Microwave shield plate of microwave oven door

A technology for shielding plates and microwave ovens, which can be used in household stoves/stoves, household heating, lighting and heating equipment, etc. It can solve the problems of high cost and difficult processing of microwave shielding structures, and achieve low manufacturing costs, simple structure, and difficult processing small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

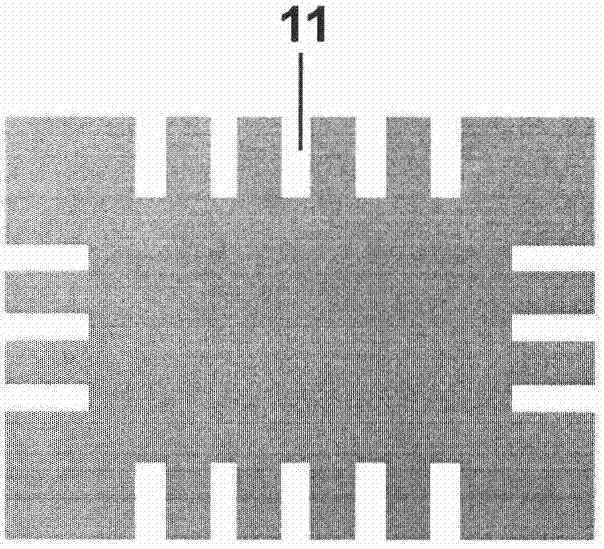

[0027] The schematic diagram of the structure of the microwave shielding plate in the first embodiment of the present invention and the schematic diagram of its relative position in contact with the metal furnace mouth of the microwave oven door are shown in Figure 2, wherein: Figure 2a Before the microwave shielding plate is pressed against the metal furnace mouth, that is: before the furnace door is closed, Figure 2b After the microwave shielding plate and the metal furnace mouth are pressed together, that is, after the furnace door is closed. The microwave shielding plate 21 of this embodiment is selected from an aluminum alloy plate with elastic and plastic deformation capabilities, and the thickness of the plate is 1mm. The surrounding of the shielding plate adopts a rectangular opening structure. The opening width A of the rectangular opening 22 is 3mm, and the opening depth is 20mm. Adjacent openings The width of the rectangular protrusions 23 between them (that is: t...

Embodiment 2

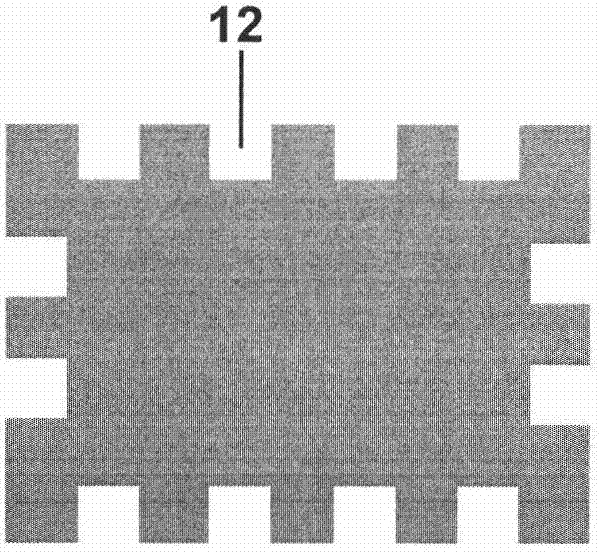

[0029] The structure diagram of the microwave shielding plate of the microwave oven door described in the second embodiment of the present invention is as follows: image 3shown. The microwave shielding plate of this embodiment is made of 304 stainless steel plate with elastic and plastic deformation ability, and the thickness of the plate is 1mm. The surrounding of the shielding plate adopts a rectangular opening structure, the opening width C is 2mm, the opening depth D is 12mm, and the corners of the rectangular opening are rounded. Arc structure, the arc radius R is 1mm, and the rectangular protrusions between adjacent openings adopt two sizes, namely: the width E of the rectangular protrusions (ie: the opening distance E) is 2 mm, and the width F of the rectangular protrusions (ie: the opening distance E) is 2 mm. The distance F) is 10mm. The outer dimension of the microwave shielding plate is 10mm larger than the size of the metal furnace mouth of the microwave oven. Th...

Embodiment 3

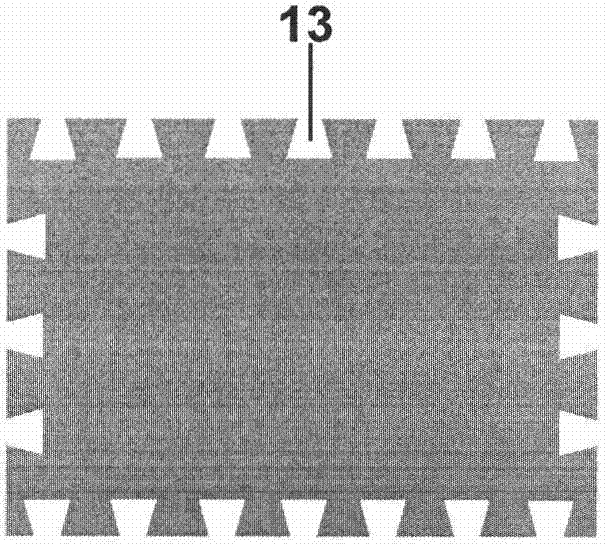

[0031] The structural schematic diagram of the microwave shielding plate of the microwave oven door described in the third embodiment of the present invention is as follows Figure 4 shown. The microwave shielding plate in this embodiment is made of 304 stainless steel plate with elastic and plastic deformation ability, the thickness of the plate is 0.8mm, and two opening structures of rectangle and isosceles trapezoid are adopted around the shielding plate. The width G of the rectangular opening is 2mm, the opening depth H is 12mm, the corners of the rectangular opening adopt a circular arc structure, the radius R of the circular arc is 1mm, and the width I of the rectangular protrusions between adjacent openings (that is: opening distance I) is 2mm. The upper bottom dimension J of the isosceles trapezoidal opening is 2mm, the lower bottom dimension K is 4mm, and the opening depth L is 12mm. The outer dimension of the microwave shielding plate is 12mm larger than the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com