High-efficiency, electrostatic-prevention and laminated magnetic bead

An anti-static, stacking technology, applied in the direction of preventing/reducing unwanted electric/magnetic influences, circuits, electrical components, etc., can solve problems such as unreasonable graphic structure, coil open circuit failure, poor antistatic effect, etc., to achieve Ensure coil current carrying capacity, reduce coil temperature rise, and enhance anti-mite performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

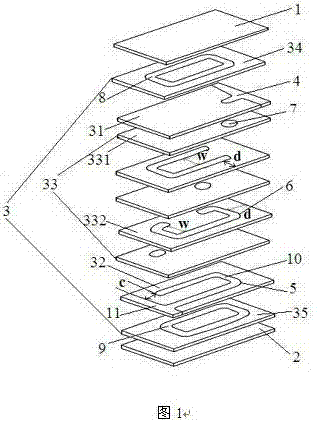

[0021] see Figure 1 ~ Figure 2 A high-efficiency anti-static laminated chip magnetic bead, comprising an upper cover 1, a lower cover 2, and a plurality of superimposed dielectric layers 3 sandwiched between the upper cover 1 and the lower cover 2, the upper dielectric The layer 31 is embedded with an upper lead-out electrode 4 extending to the side of the dielectric layer 3, the lower dielectric layer 32 is embedded with a lower lead-out electrode 5 extending to the side of the dielectric layer 3, and each layer of the intermediate dielectric layer 33 is embedded with an inner The electrode coil 6 or the connection point 7, the intermediate dielectric layer A331 with the connection point 7 and the intermediate dielectric layer B332 with the inner electro...

PUM

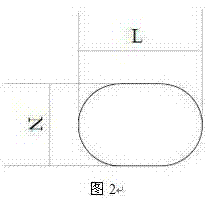

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com