Separator for alkaline batteries, and alkaline battery

A technology for alkaline batteries and separators, applied in the direction of alkaline batteries, battery pack parts, electrical components, etc., can solve problems such as difficult to increase at the same time, and achieve the effect of reducing the resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

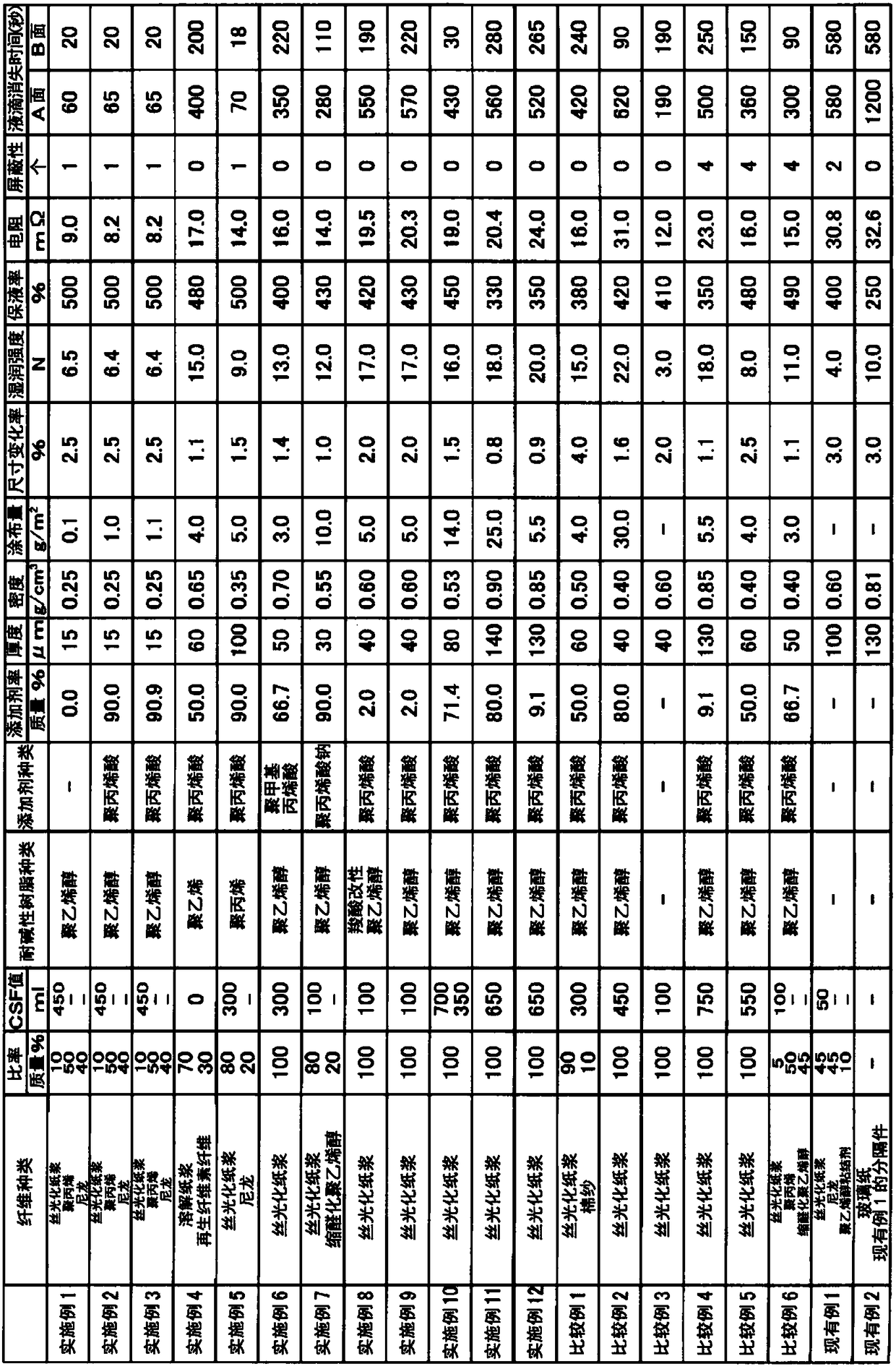

Examples

Embodiment 1

[0170] 10% by mass of a raw material having a CSF value of 450 ml obtained by beating and mercerizing softwood kraft pulp, 50% by mass of polypropylene fibers, and 40% by mass of nylon fibers were mixed and short-wired to obtain a substrate. A coating liquid in which polyvinyl alcohol was dissolved was applied on the base material and dried to obtain a thickness of 15 μm and a density of 0.25 g / cm 3 , coating amount 0.1g / m 2 , Dimensional change rate of 2.5%, wet strength of 6.5N, liquid retention rate of 500%, electrical resistance of 9.0mΩ, shielding property of 1 piece, droplet disappearance time of 60 seconds on the A side and 20 seconds on the B side.

Embodiment 2

[0172] On a base material subjected to short-wire papermaking using the same raw materials as in Example 1, a coating solution in which polyvinyl alcohol and polyacrylic acid were dissolved was applied and dried to obtain a thickness of 15 μm and a density of 0.25 g / cm 3 , coating amount 1.0g / m 2 , Dimensional change rate of 2.5%, wet strength of 6.4N, liquid retention rate of 500%, electrical resistance of 8.2mΩ, shielding property of 1, droplet disappearance time of 65 seconds on the A side and 20 seconds on the B side. In addition, the additive content rate of this coating layer was 90.0%.

Embodiment 3

[0174] On a base material subjected to short-wire papermaking using the same raw materials as in Example 1, a coating solution in which polyvinyl alcohol and polyacrylic acid were dissolved was applied and dried to obtain a thickness of 15 μm and a density of 0.25 g / cm 3 , coating amount 1.1g / m 2 , Dimensional change rate of 2.5%, wet strength of 6.4N, liquid retention rate of 500%, electrical resistance of 8.2mΩ, shielding property of 1, droplet disappearance time of 65 seconds on the A side and 20 seconds on the B side. In addition, the additive content rate of this coating layer was 90.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com