Manual pressure-maintaining and skipping floating reversing valve for tractor

A tractor and reversing valve technology, applied in the field of hydraulic reversing valve, can solve the problems of troublesome maintenance, complex structure, large product volume, etc., and achieve the effects of reducing static settlement, reducing processing difficulty and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

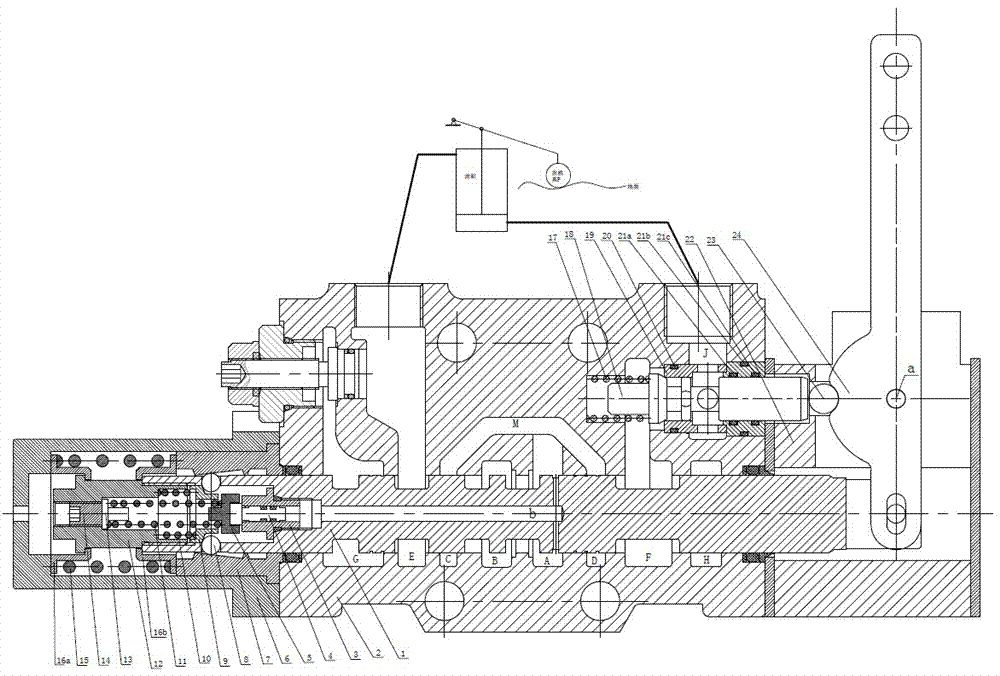

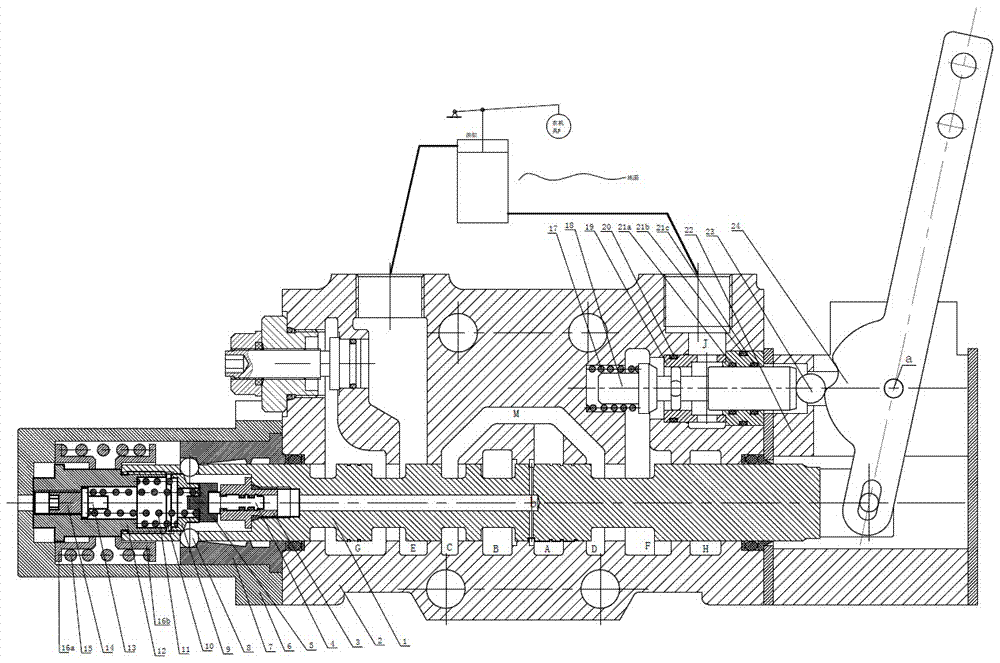

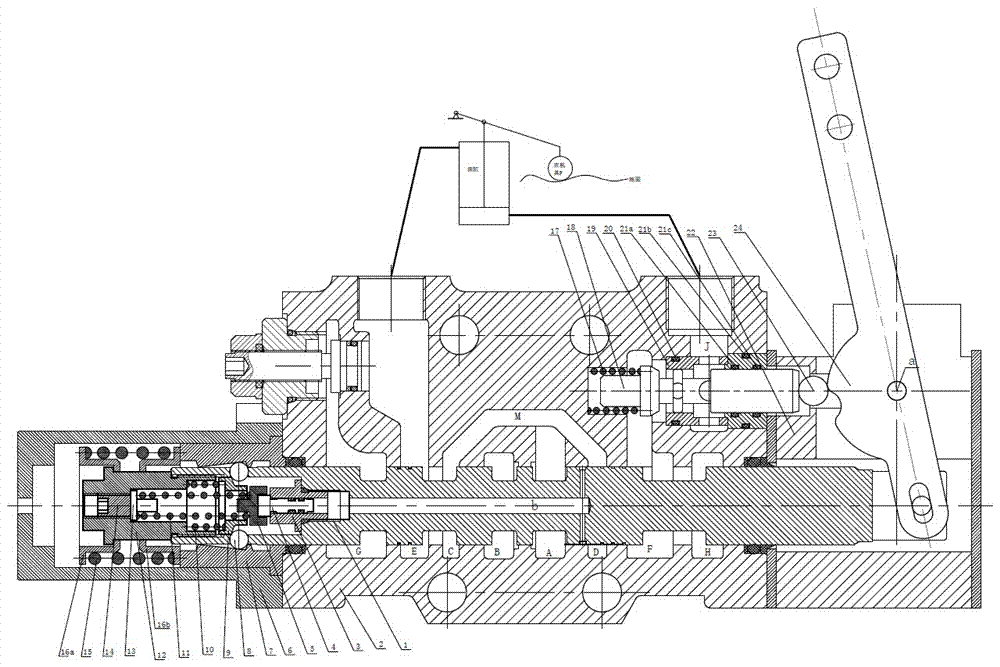

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-5 As shown, the tractor manual pressure-holding jump floating reversing valve includes a valve core 1, a valve body 2, a front end cover 6 and a rear end cover 22. The valve core 1 is assembled in the valve body 2, and the front and rear ends of the valve body 2 are respectively Assemble the front end cover 6 and the rear end cover 22; it is characterized in that it also includes an oil passage conversion lock arranged in the valve body, a cam handle mechanism arranged in the rear end cover, a jump mechanism arranged in the valve core and a The positioning mechanism in the cover; the oil passage conversion lock includes a lock core 18 and a lock body 19, and the lock body 19 is assembled in the valve body 2 and is guaranteed by No. 1 to No. 4 sealing rings 20, 21a, 21b, and 21c. The cavity is in a sealed state, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com