Hydraulic pressure expander

A technology of expander and hydraulic pressure, which is applied in the direction of underwater operation equipment, fluid pressure actuators, servo motor components, etc. It can solve the problems of reduced working life of components, increased pressure loss, and reduced tool efficiency, so as to improve reliability Enhanced performance and longevity, increased operating depth, and less tidal current disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

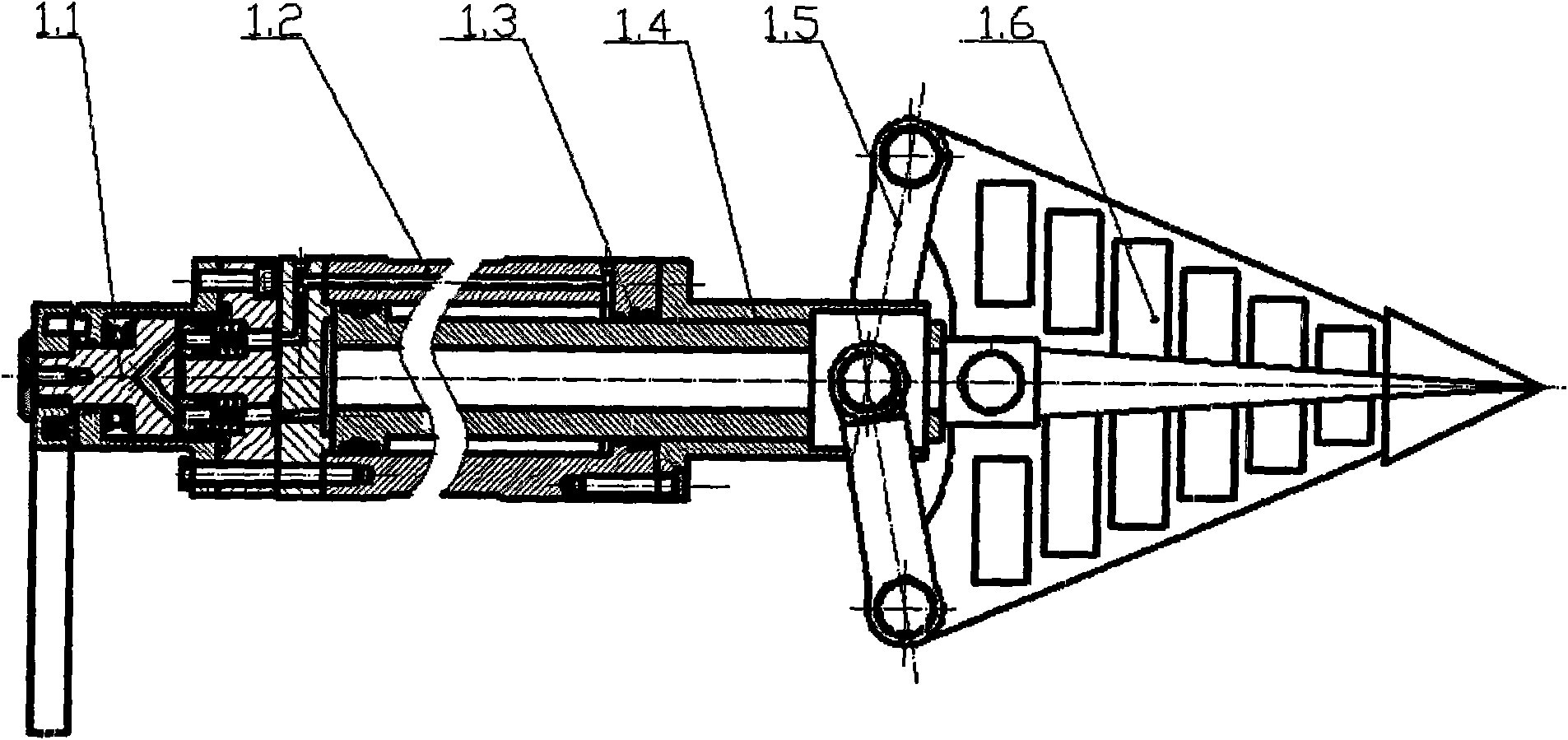

[0028] figure 1 The overall structure of the seawater hydraulic expander is given, including the reversing valve 1.1, the seawater hydraulic cylinder and the expansion mechanism. The reversing valve is connected with the seawater hydraulic cylinder to control the expansion and contraction of the seawater hydraulic cylinder; the seawater hydraulic cylinder is connected with the expansion mechanism, and the expansion arm is opened and closed through expansion and contraction to realize expansion and traction.

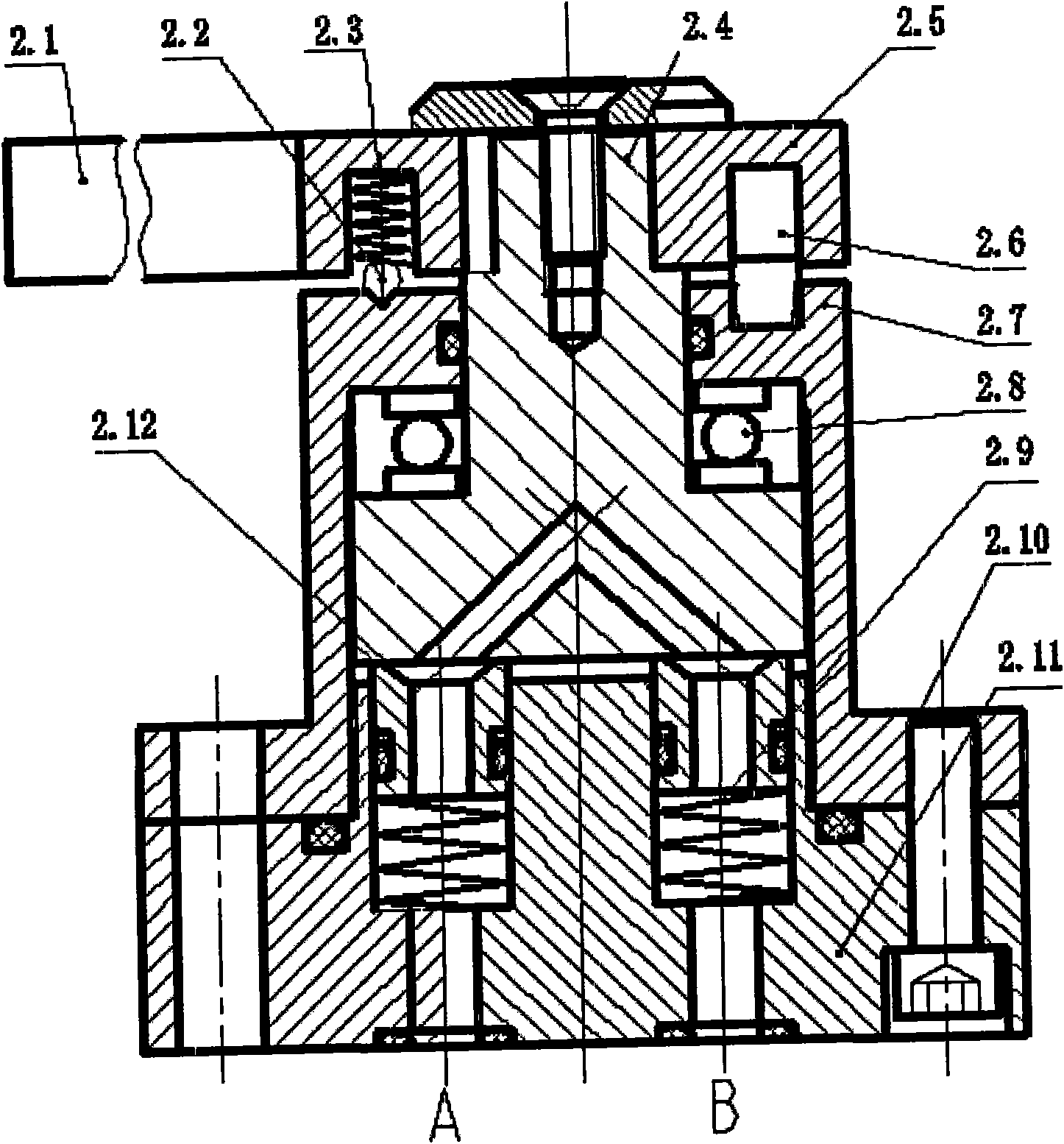

[0029] figure 2 It is a structural schematic diagram of a reversing valve, and the reversing valve includes a valve seat 2.10, a valve core 2.4, a valve body 2.7, a reversing sleeve 2.5 and a reversing handle 2.1. A spool 2.4 is placed in the valve body 2.7, and the upper end of the spool 2.4 stretches out from the valve body 2.7 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com