Plugging method and plugging device for high sub-level open draw shaft mouth

A plugging device and a technology for sky-sliding wells, which are applied in sealing/isolation, wellbore/well components, earthwork drilling and mining, etc., and can solve problems such as the impact of mining equipment and miners' access, hidden safety hazards, and illegal operations, etc., to achieve plugging Ease of operation, safe construction, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

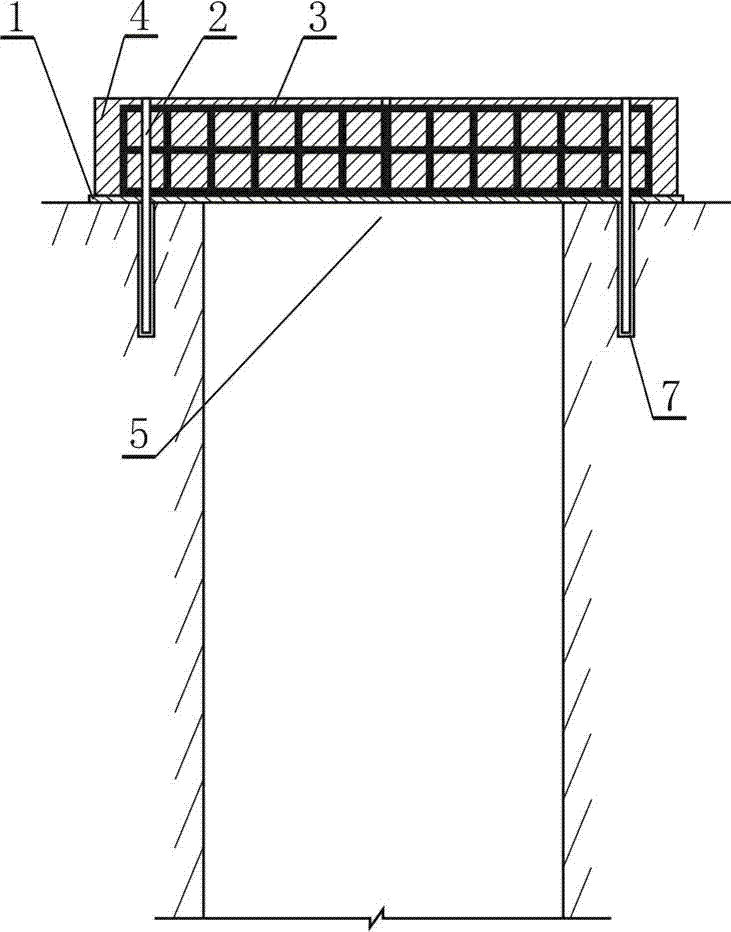

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or replacements made according to the teaching of the present invention belong to the protection scope of the present invention.

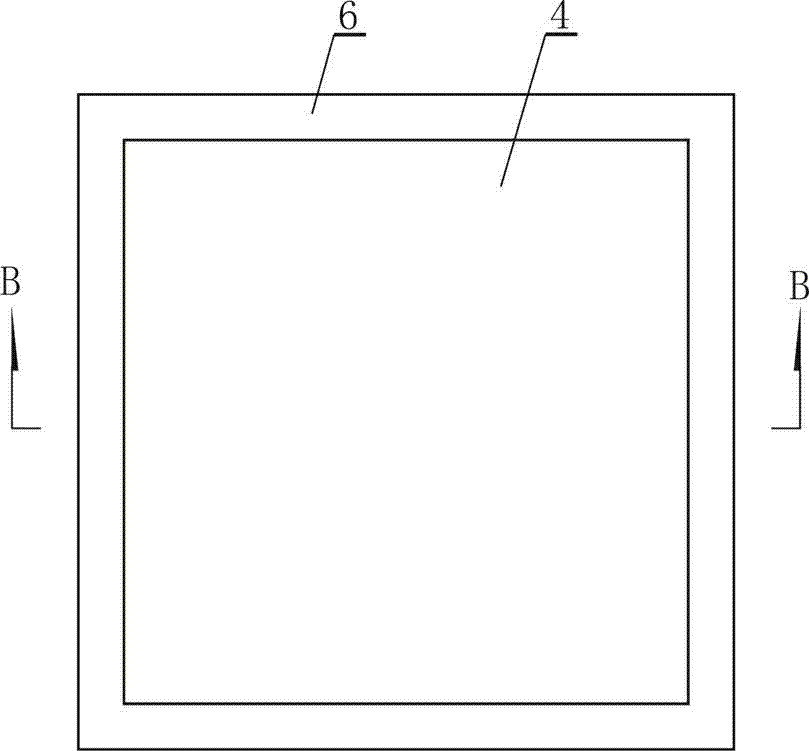

[0018] Such as figure 1 , 2 As shown, the method of the present invention includes on-site treatment, material preparation, and plugging procedures, specifically:

[0019] The on-site treatment system treats around the wellhead according to the range of 1.5 to 2.5 times of the designed wellhead diameter, leveling and cleaning up;

[0020] The material preparation is to prepare the structural substrate according to 1.5 to 2.5 times the diameter of the designed wellhead, and set bridging holes along the periphery of the substrate, and prepare the same number of anchor rods 2 corresponding to the number of bridging holes 9; prepare the metal according to the size of the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com