Uniform crushing device for rubber

A crushing device and uniform technology, applied in the direction of filter screen, grid, solid separation, etc., can solve the problems of long crushing time and uneven particle size of rubber particles, achieve uniform particle size, reduce occupied space, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

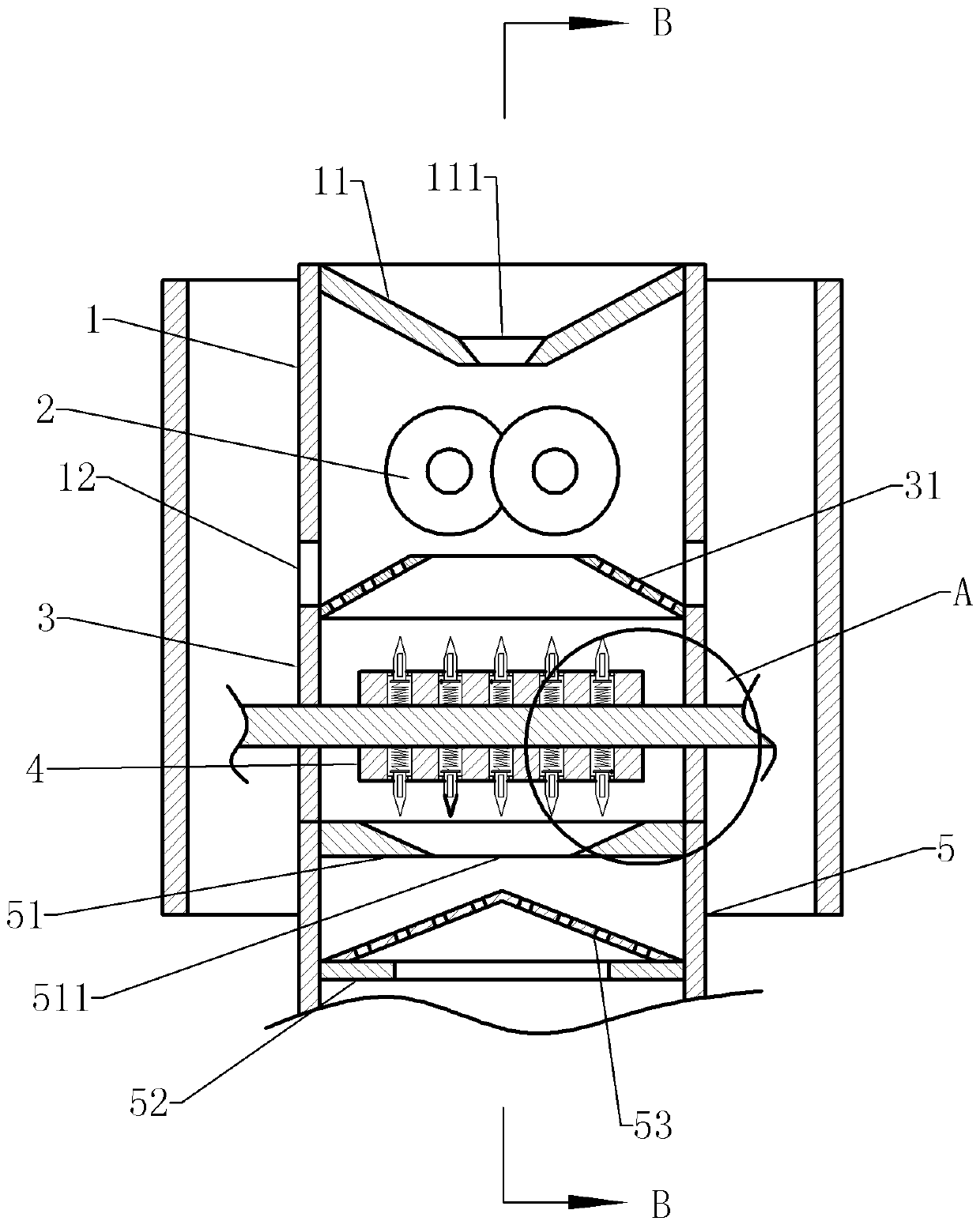

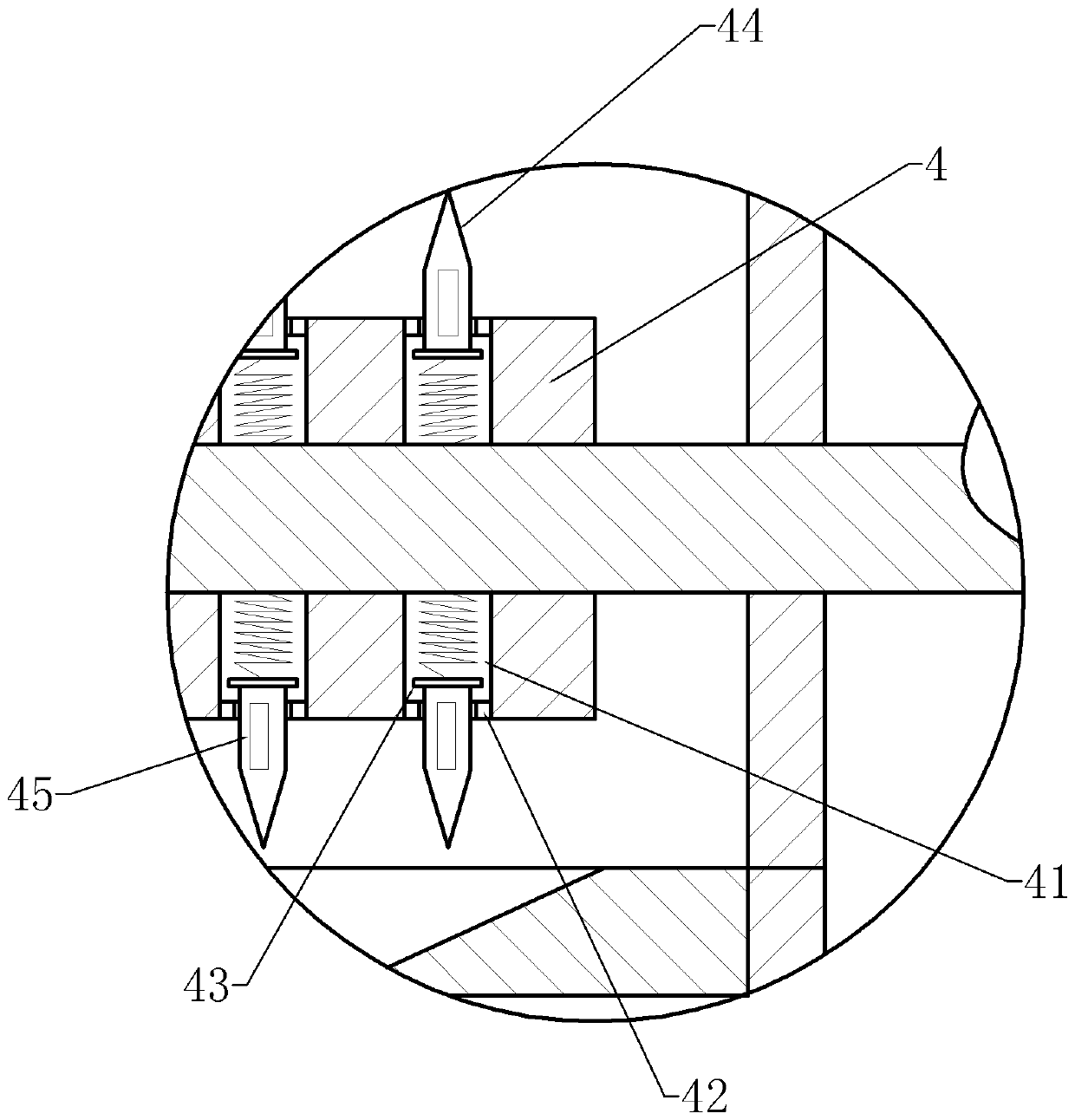

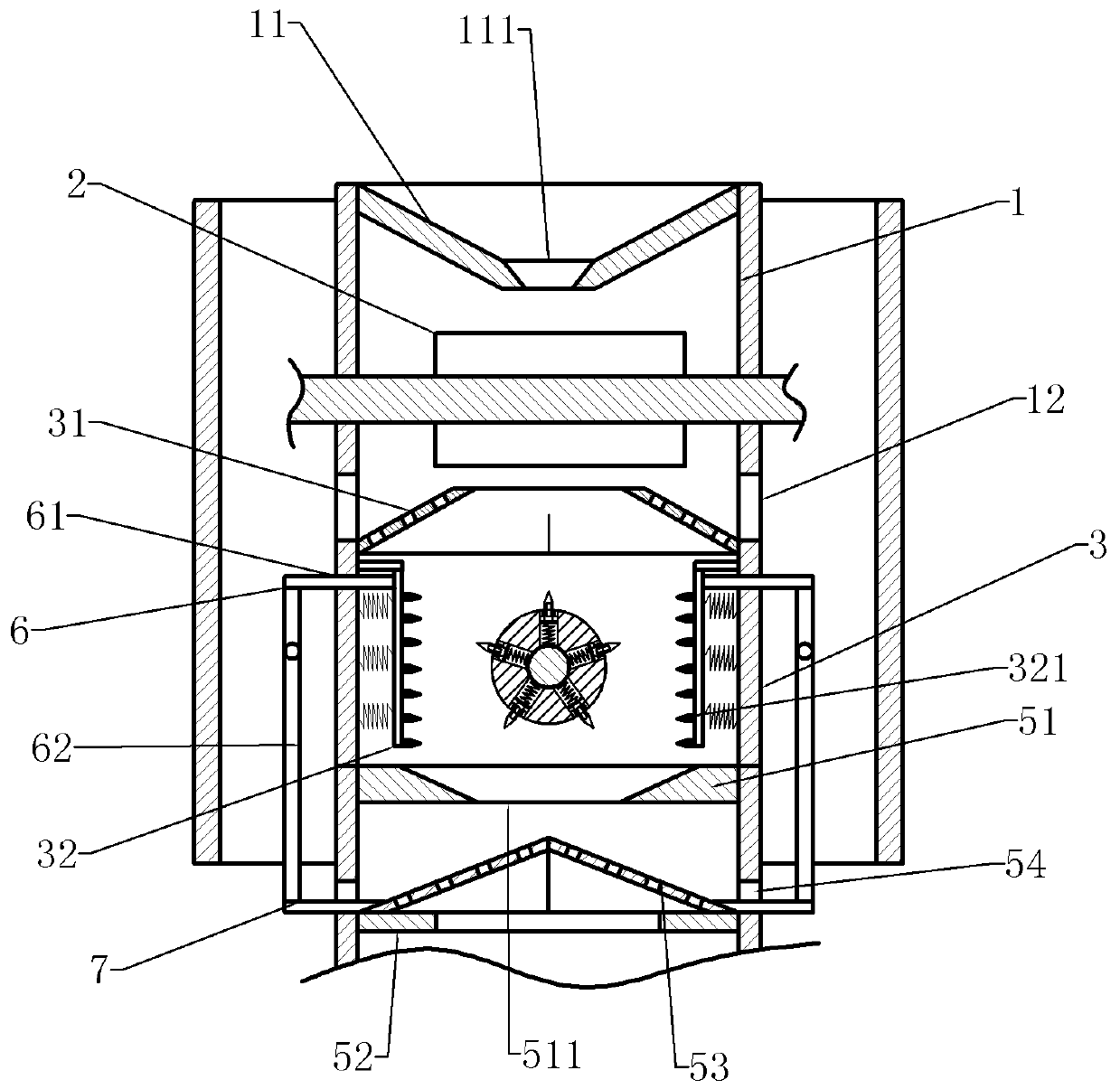

[0033] The reference signs in the accompanying drawings of the specification include: the first crushing barrel 1, the material guide cylinder 11, the discharge port 111, the collecting port 12, the crushing roller knife 2, the second crushing barrel 3, the screening net 31, and the retaining plate 32. Second shear knife 321, sleeve 4, through hole 41, limit ring 42, limit block 43, first shear knife 44, bar magnet 45, receiving barrel 5, guide block 51, guide hole 511, support block 52, screen 53, discharge port 54, push rod 6, push rod 61, pole 62, material receiving rod 7.

[0034] like figure 1 As shown, a rubber uniform crushing device includes a machine body on which two motors are arranged, and a first crushing barrel 1, a second crushing barrel 3 and a receiving barrel 5 arranged in sequence from top to bottom are arranged in the body. The top of the first crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com