Roll-cutting shear quality monitoring system and method based on laser and visual inspection

A visual inspection and quality monitoring technology, applied in general control systems, control/regulation systems, program control, etc., can solve the dependence of detection accuracy and evaluation standards, time-consuming and labor-intensive, and cannot be comprehensive, real-time, accurate and traceable Problems such as recording and evaluation can achieve the effect of realizing traceability and monitoring, improving the quality of cutting, and improving the level of cutting automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

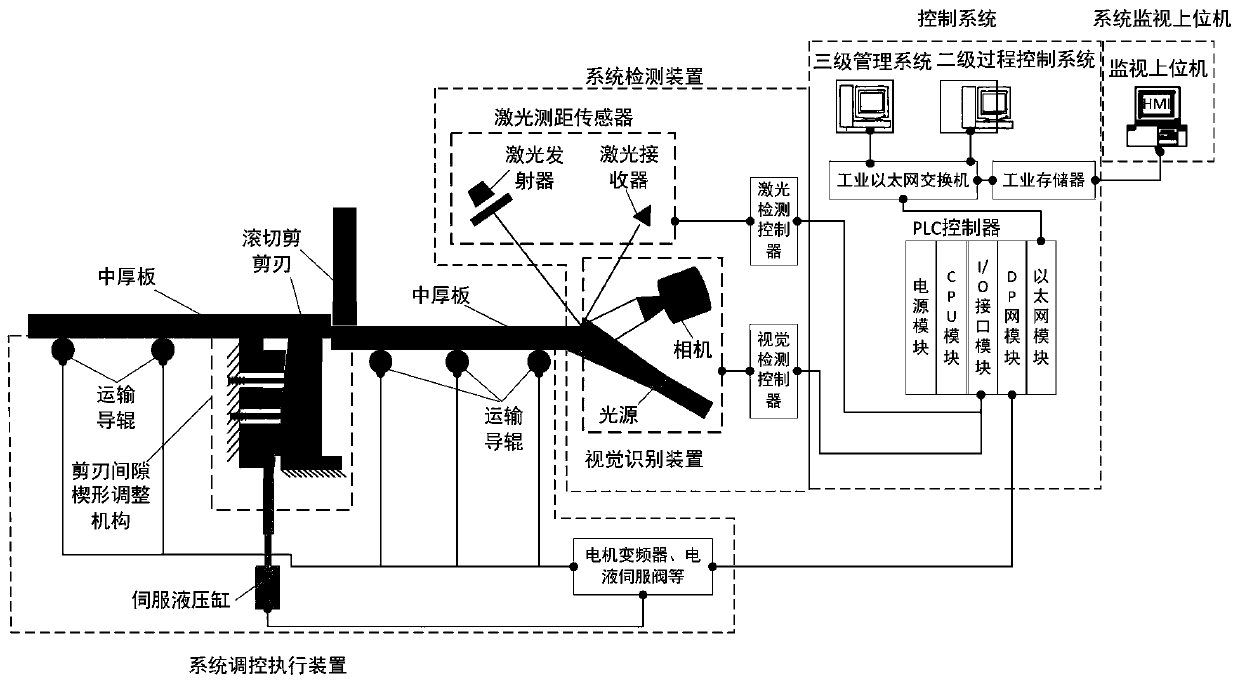

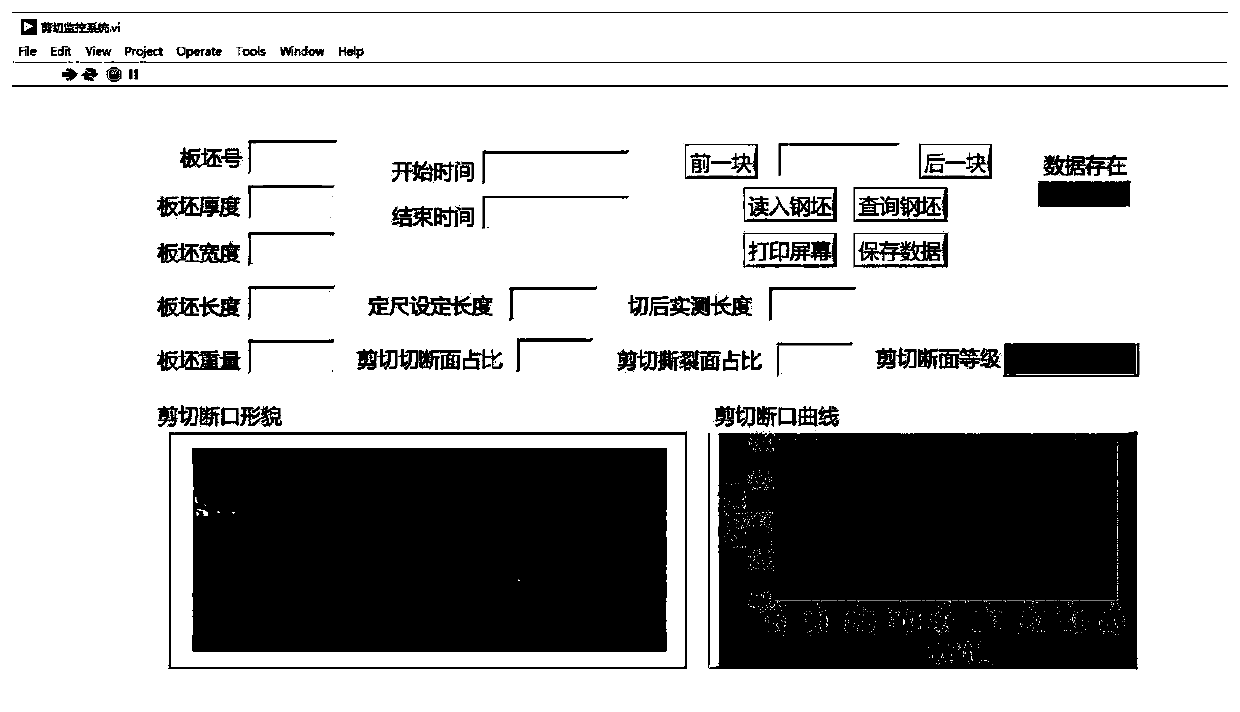

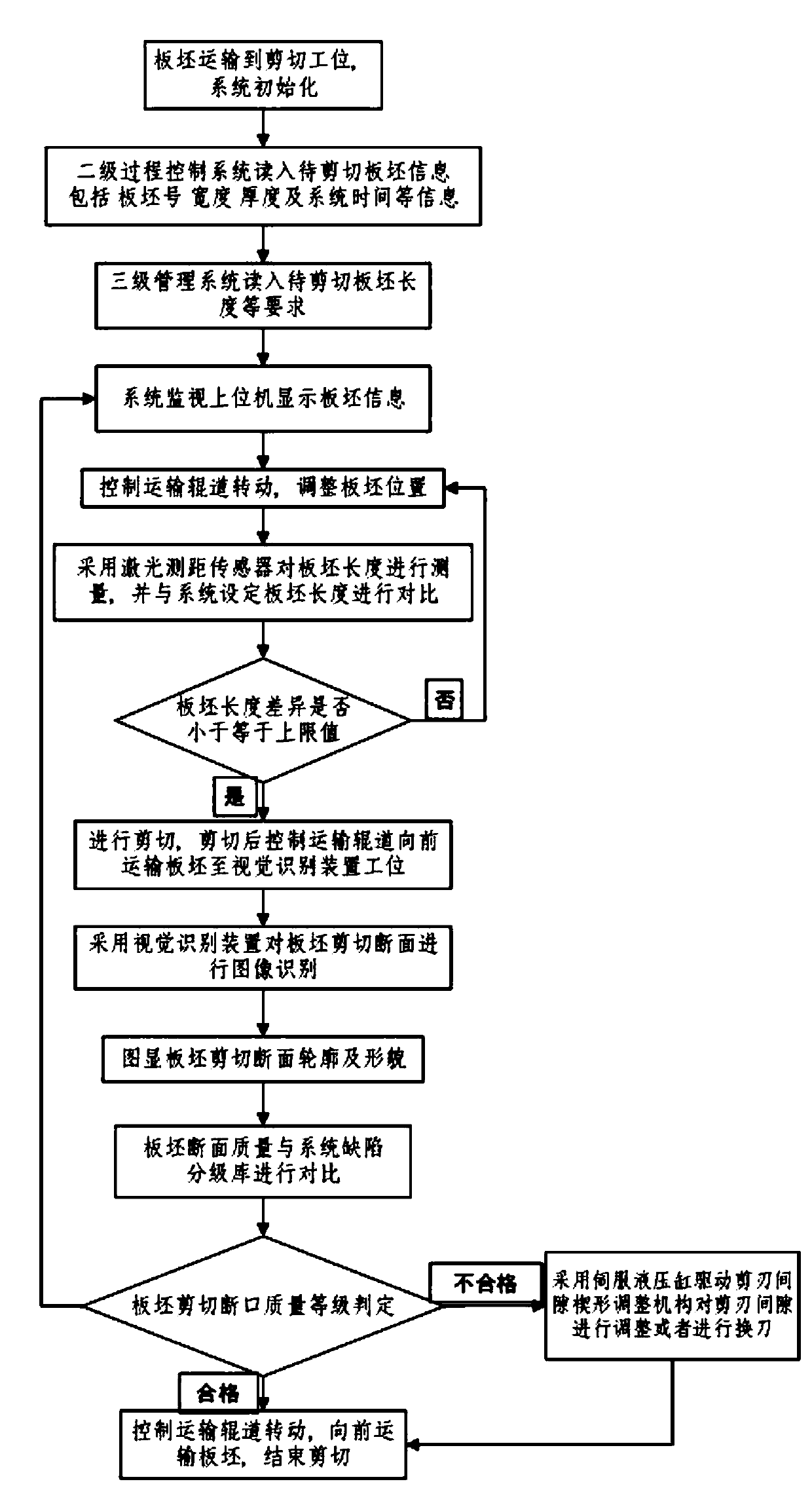

[0041] Such as figure 1 , Figure 3-12 , a rolling shear quality monitoring system based on laser and visual detection, including a system monitoring host computer, a system detection device, a system regulation execution device, and a control system, and the system monitoring host computer is used for real-time display, export, and printing of medium and thick The detection results of the quality of the shear fracture of the plate and the actual shear length of the cut-to-length; the system detection device is used to detect the quality of the shear fracture of the medium-thick plate and the length of the cut-to-length, and transmits the relevant data to the control system, and the control system is based on The detection results and the system model determine whether to start the system regulation and control actuator, and control the system regulation and control actuator to adjust the steering, speed and the size of the cutting blade gap of the adjustable speed conveying r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com