Environment-friendly oil immersion device for chain production

An environmentally friendly, oil-immersed technology, applied in transportation and packaging, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the cumbersome process of picking up the chain, consume a lot of effort, and take a long time for the chain, etc. problem, to achieve the effect of reducing the probability of washing hands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

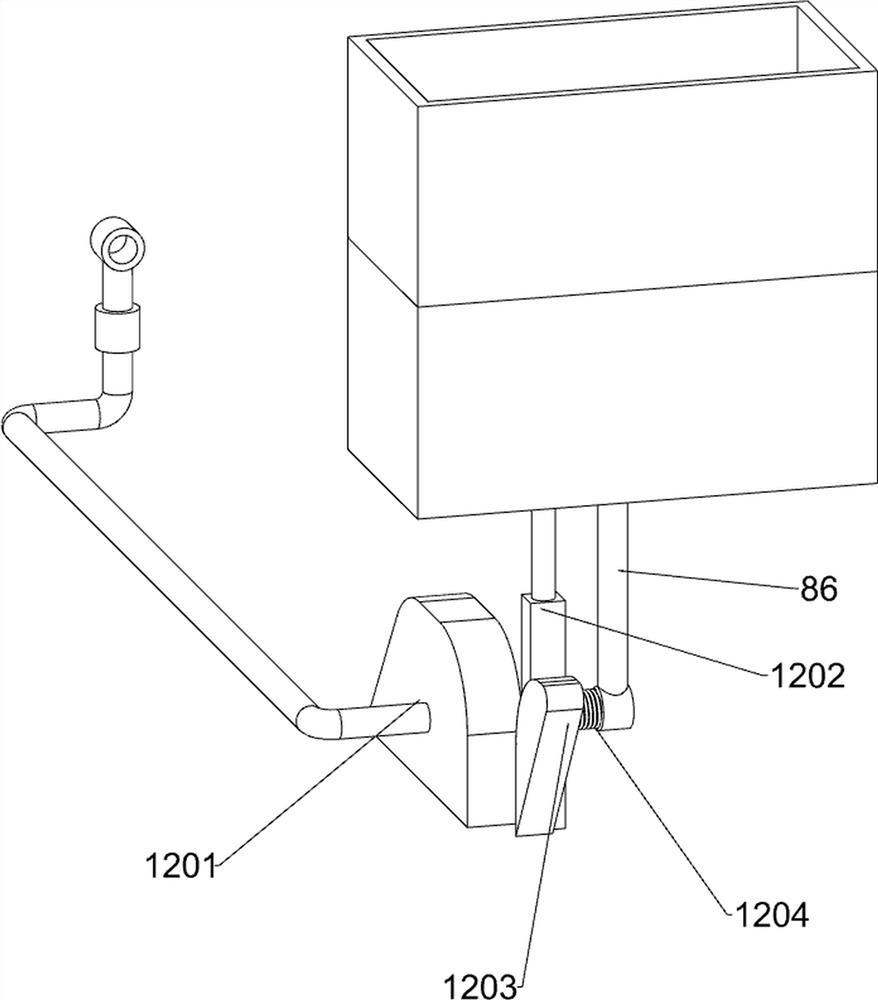

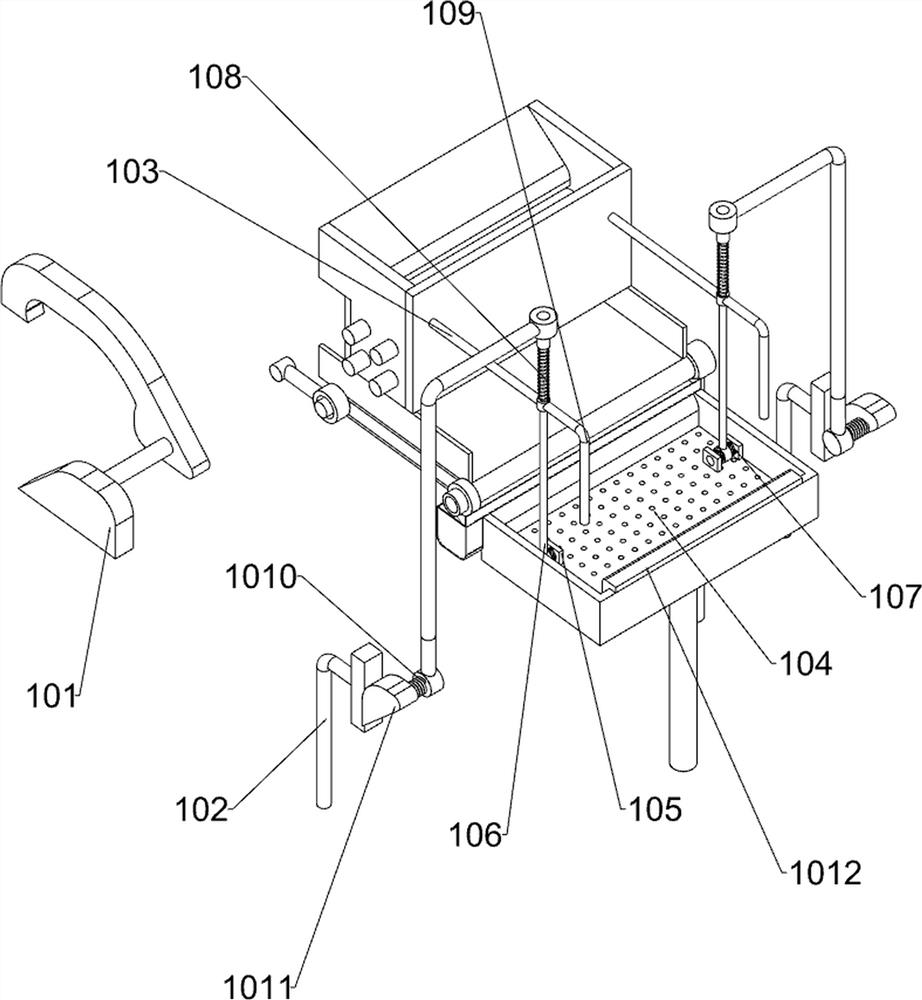

[0085] An environment-friendly oil immersion device for chain production, such as figure 1 As shown, it includes a base 1, a first support rod 2, a material storage frame 3, a derusting agent soaking and lifting mechanism 4, a water wiping mechanism 5, a conveying mechanism 6 and an oil soaking mechanism 7, and the front side of the top of the base 1 is fixed symmetrically There are first support rods 2, and a material storage frame 3 is connected between the two first support rods 2, and a derusting agent soaking and picking mechanism 4 is installed in the storage frame 3, and a wiper is installed on the front side of the material storage frame 3. Water mechanism 5, water wiping mechanism 5 cooperates with derusting agent soaking and lifting mechanism 4, conveying mechanism 6 is installed on the front side of the top of the base 1, and the conveying mechanism 6 is located below the water wiping mechanism 5, and an oil soaking mechanism is welded on the front side of the top of...

Embodiment 2

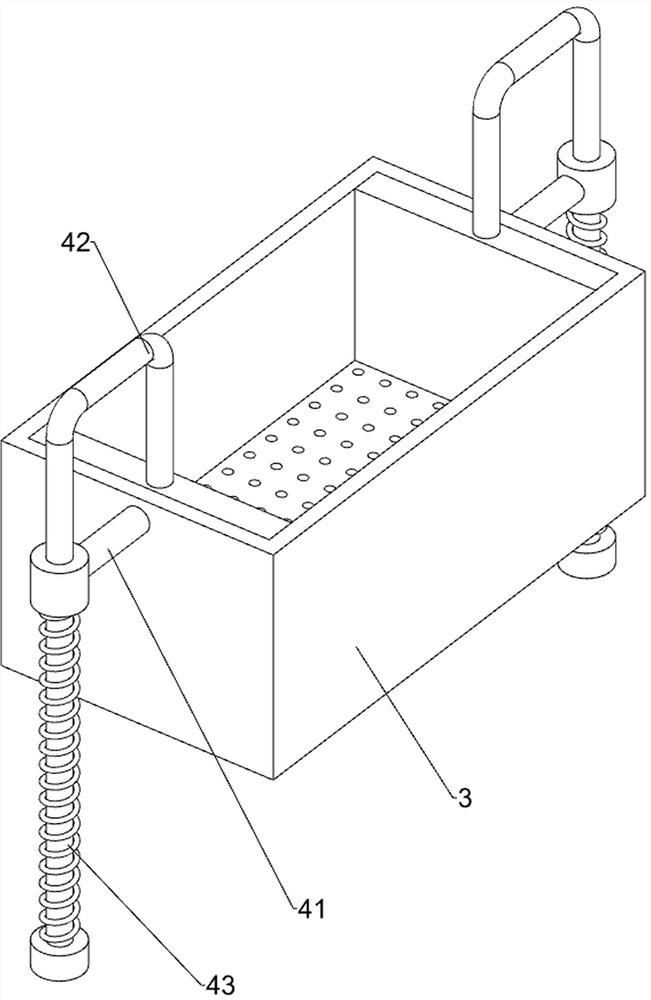

[0088] In a preferred embodiment of the present invention, as figure 2 As shown, the derusting agent soaking and lifting mechanism 4 includes a first sliding sleeve 41, a funnel-shaped screening frame 42 and a first spring 43, and the left and right sides of the storage frame 3 are symmetrically provided with the first sliding sleeve 41, and the storage frame 3 The inner sliding type is provided with a funnel-shaped screening frame 42, and the left and right sides of the funnel-shaped screening frame 42 are slidingly matched with the first sliding sleeve 41. The funnel-shaped screening frame 42 is covered with a first spring 43, and the two ends of the first spring 43 are respectively Connected to the funnel-shaped screening frame 42 and the first sliding sleeve 41.

[0089] Workers need to put the chain on the funnel-shaped screening frame 42 first. After the chain is positioned on the funnel-shaped screening frame 42, the rust remover in the material storage frame 3 can car...

Embodiment 3

[0091] In a preferred embodiment of the present invention, as figure 1 with Figure 3-Figure 13 As shown, the water wiping mechanism 5 includes a connecting frame 51, a first rotating shaft 52, and a rotating wiping rod 53. The connecting frame 51 is installed on the front side of the storage frame 3, and the first rotating shaft is connected in a rotating manner between the left and right sides of the connecting frame 51. 52. A rotating wiping rod 53 is installed on the first rotating shaft 52, and the rotating wiping rods 53 cooperate with each other.

[0092] Part of the derusting agent will remain on the completed chain due to derusting, and the derusting agent on the chain may affect the oil immersion work of the chain, so the chain picked up by the funnel-shaped screening frame 42 will slide into the connecting frame 51, and the connecting frame will The chain in 51 will slide down between the rotating wiping rods 53. At this time, the worker needs to control the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com