Regular shearing and packaging equipment for fiber material for manufacturing masks

A fiber material and packaging equipment technology, which is applied in the field of regular cutting and packaging equipment for fiber materials used in masks, can solve the problems that fiber materials consume a lot of effort, and it is difficult to cut fiber materials into uniform specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

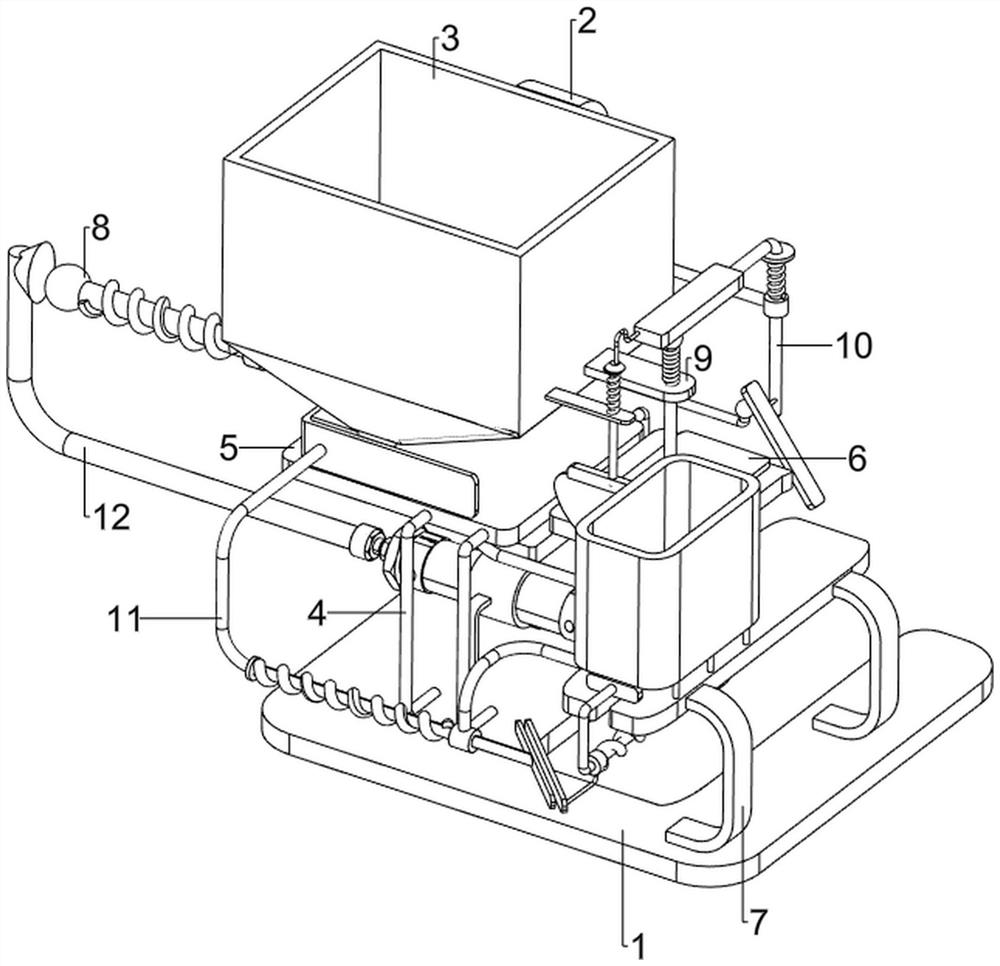

[0064] A kind of fiber material regular cutting packaging equipment for making masks, such as figure 1As shown, it includes a base plate 1, a first support rod 2, a discharge frame 3, a second support rod 4, a first table plate 5, a shearing mechanism 6 and a packaging mechanism 7, and the rear side of the top of the base plate 1 is fixed with a first Support rods 2, the top left side of the first support rod 2 is fixedly connected with a discharge frame 3, the rear side of the top of the bottom plate 1 is symmetrically provided with a second support rod 4, and the tops of the left and right second support rods 4 are connected with a first Table 5, a shearing mechanism 6 is installed on the first table 5, a packing mechanism 7 is arranged on the top front side of the bottom plate 1, and the packing mechanism 7 cooperates with the shearing mechanism 6.

[0065] When the worker needs to cut and pack the fiber material, the worker first needs to put the fiber material into the di...

Embodiment 2

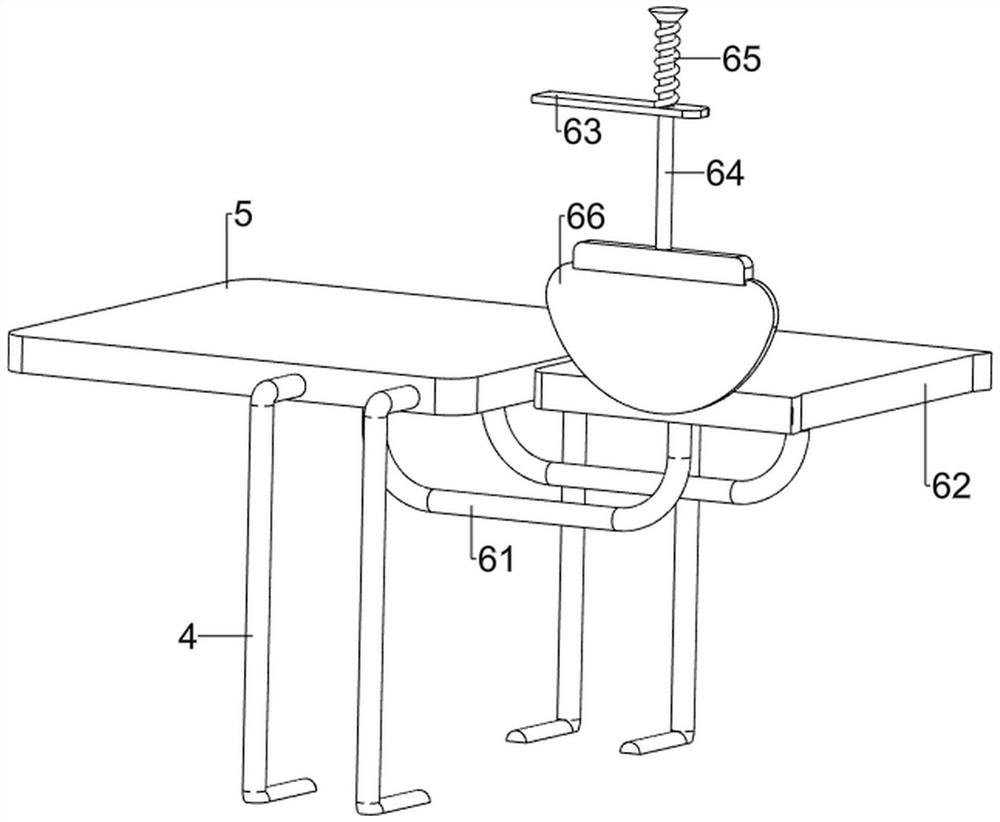

[0067] In a preferred embodiment of the present invention, as figure 2 As shown, the shearing mechanism 6 includes a first connecting rod 61, a second table 62, a first fixed plate 63, a cutting bar 64, a first spring 65 and a cutter 66, and the bottom of the first table 5 is welded with a first The connecting rod 61, the top of the front side of the first connecting rod 61 is fixedly connected with the second table board 62, the lower part of the front side of the discharge frame 3 is welded with the first fixed plate 63, and the first fixed plate 63 is provided with a sliding type cutting rod 64, The top of the cutting bar 64 is sheathed with a first spring 65, and the two ends of the first spring 65 are respectively connected to the first fixed plate 63 and the cutting bar 64, and the bottom end of the cutting bar 64 is equipped with a cutting knife 66.

[0068] After the fiber material is positioned on the first table board 5, the workman needs to take the fiber material ...

Embodiment 3

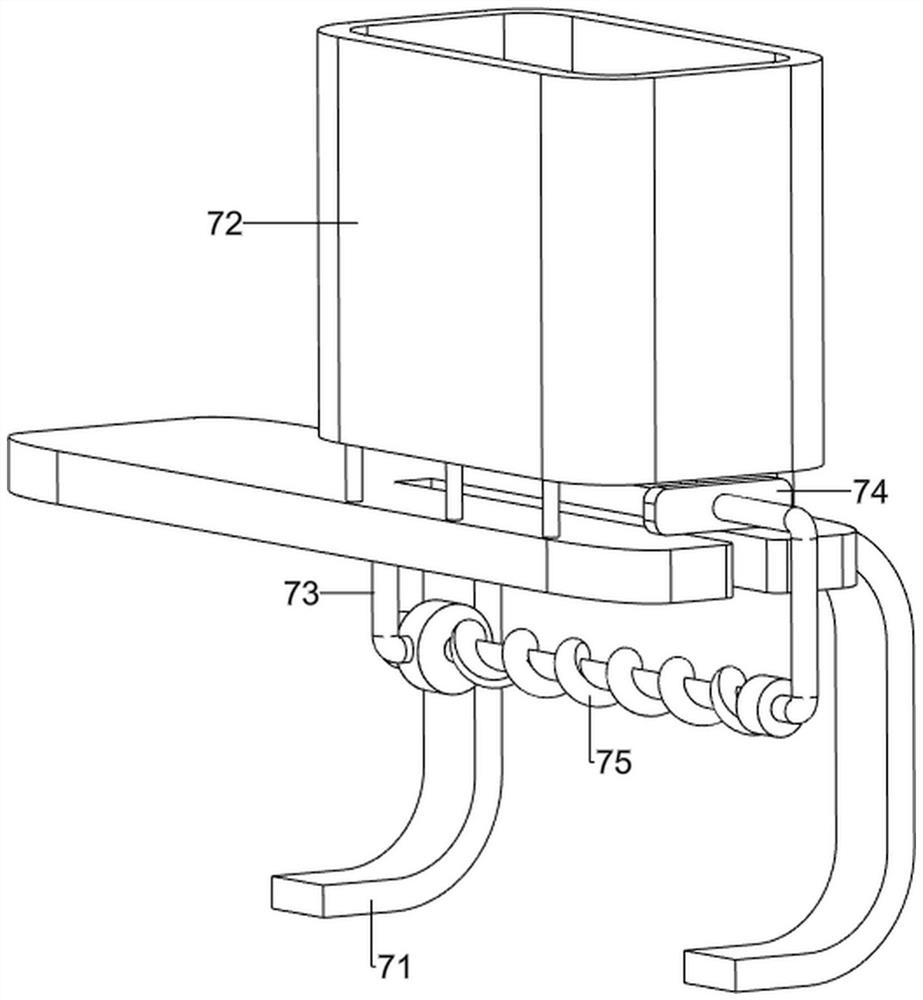

[0070] In a preferred embodiment of the present invention, as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the packaging mechanism 7 includes a third support seat 71, a box frame assembly 72, a first fixed frame 73, a first push frame 74 and a second spring 75, and a third support seat is symmetrically arranged on the front side of the bottom plate 1. 71, between the tops of the two third support bases 71, a box frame assembly 72 is affixed, and the middle part of the bottom end of the box frame assembly 72 is affixed with a first fixed frame 73, and the sliding type is provided with a first fixed frame 73 in the first fixed frame. Pushing frame 74, the first pushing frame 74 is slidably matched with putting box frame assembly 72 bottoms; On a push frame 74.

[0071] When the worker needs to pack the cut fiber material, the worker first needs to put the packing box into the box frame assembly 72, and then the worker needs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com