A feeding device for non-destructive testing of steel pipes

A technology of non-destructive testing and feeding device, which is used in measurement devices, analysis materials, transportation and packaging, etc., can solve the problems of heavy workload, time-consuming and labor-intensive testing personnel, and improve stability, improve testing quality, and ensure smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

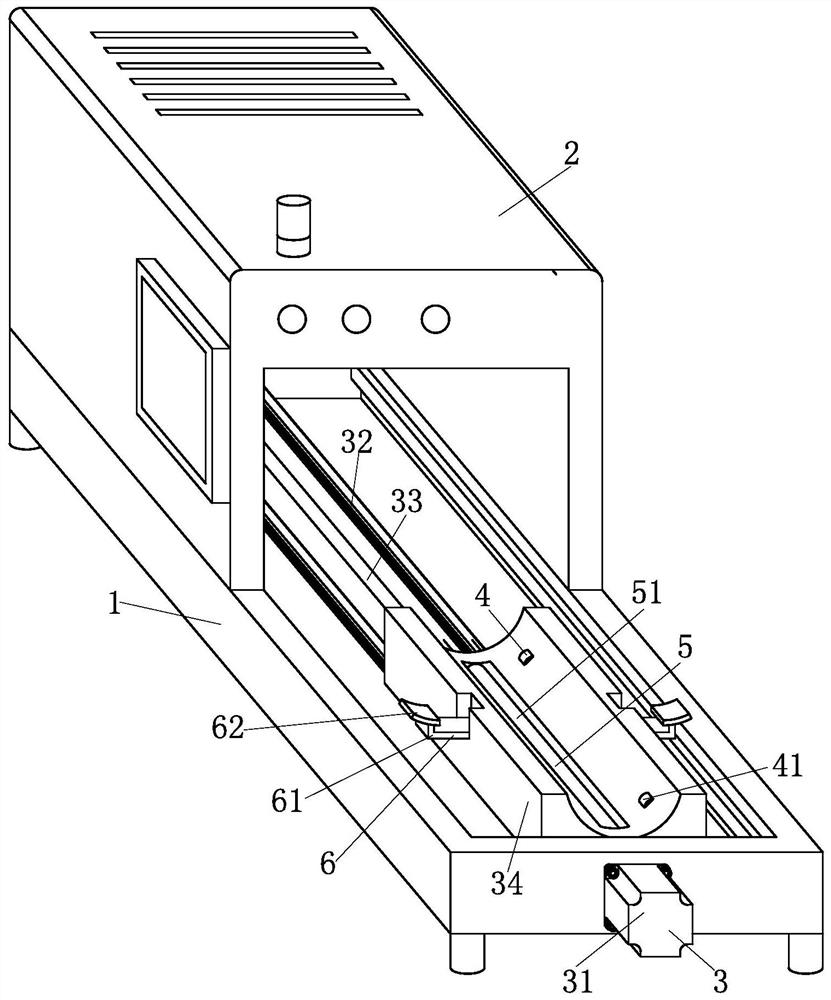

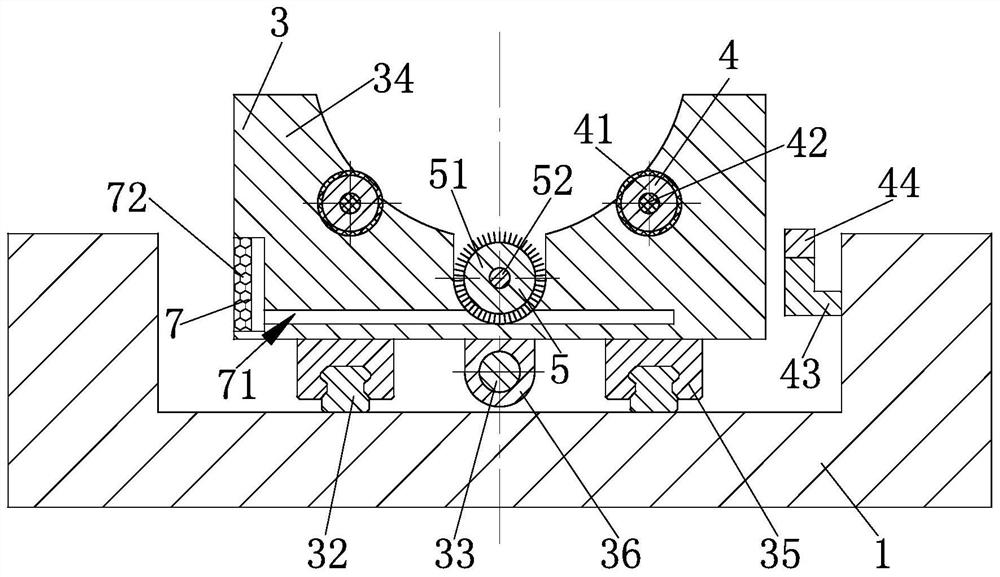

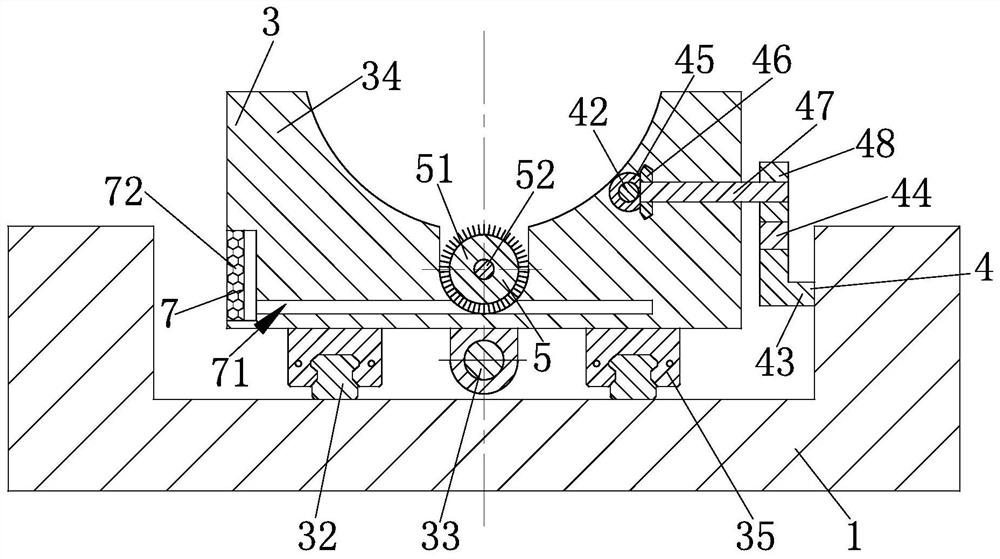

[0027] like Figure 1 - Figure 8 As shown in, for a steel pipe according to the present invention, non-destructive testing feeding apparatus includes a base 1, a testing machine 2, the feed structure 3, the structure 4 is rotated, the cleaning structure 5, 6 and cleaning structure holding structure 7, for play and said base is fixed to the top supporting the role of other components for the mounting of a testing machine for non-destructive inspection of the inner tube 2, in the interior of the base 1 is mounted into the steel pipe to be tested for the detection region is detected the feed structure 3; the internal structure 3 of said feed drive mounted for rotation detection of the rotation steel pipe structure 4, mounted inside the structure 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com