Clamping and fixing device for automobile welding

A clamping and fixing, automobile technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of troublesome welding of auto parts, inability to fix auto parts, affecting the work efficiency of staff, etc., to improve work efficiency and improve The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

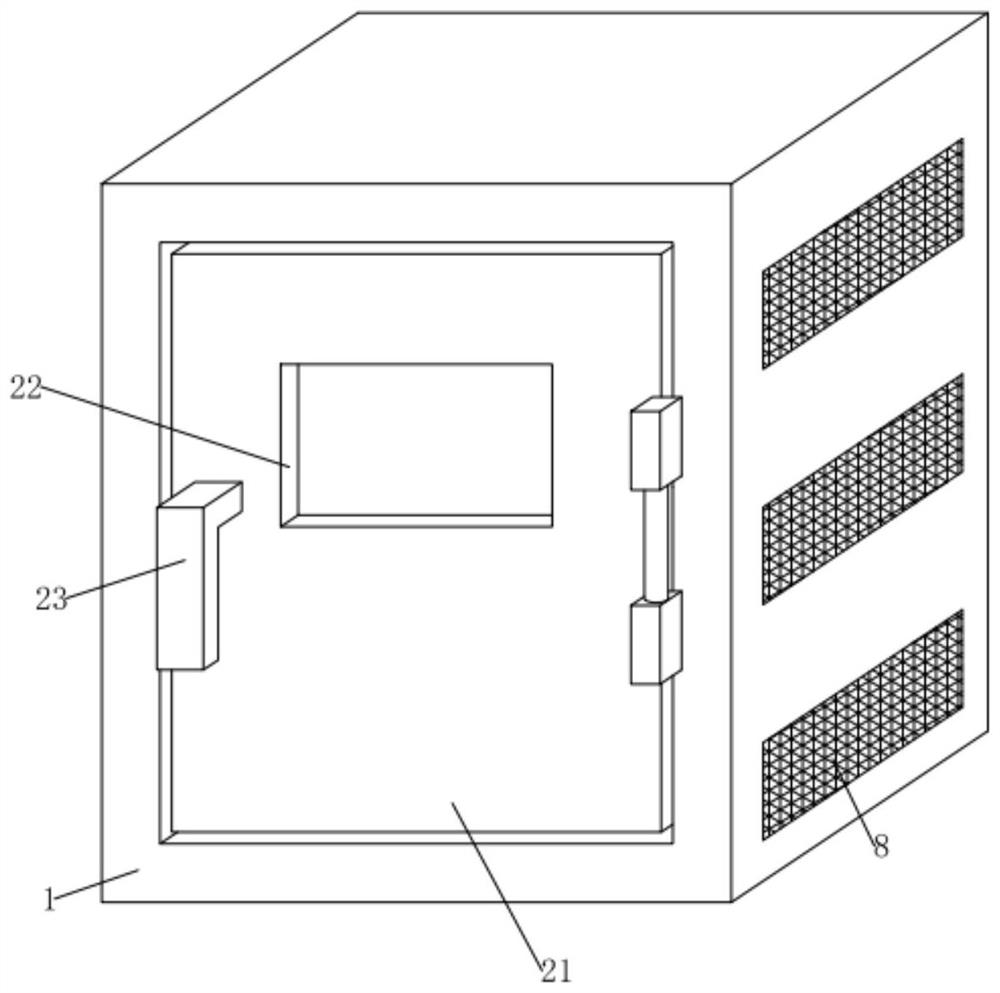

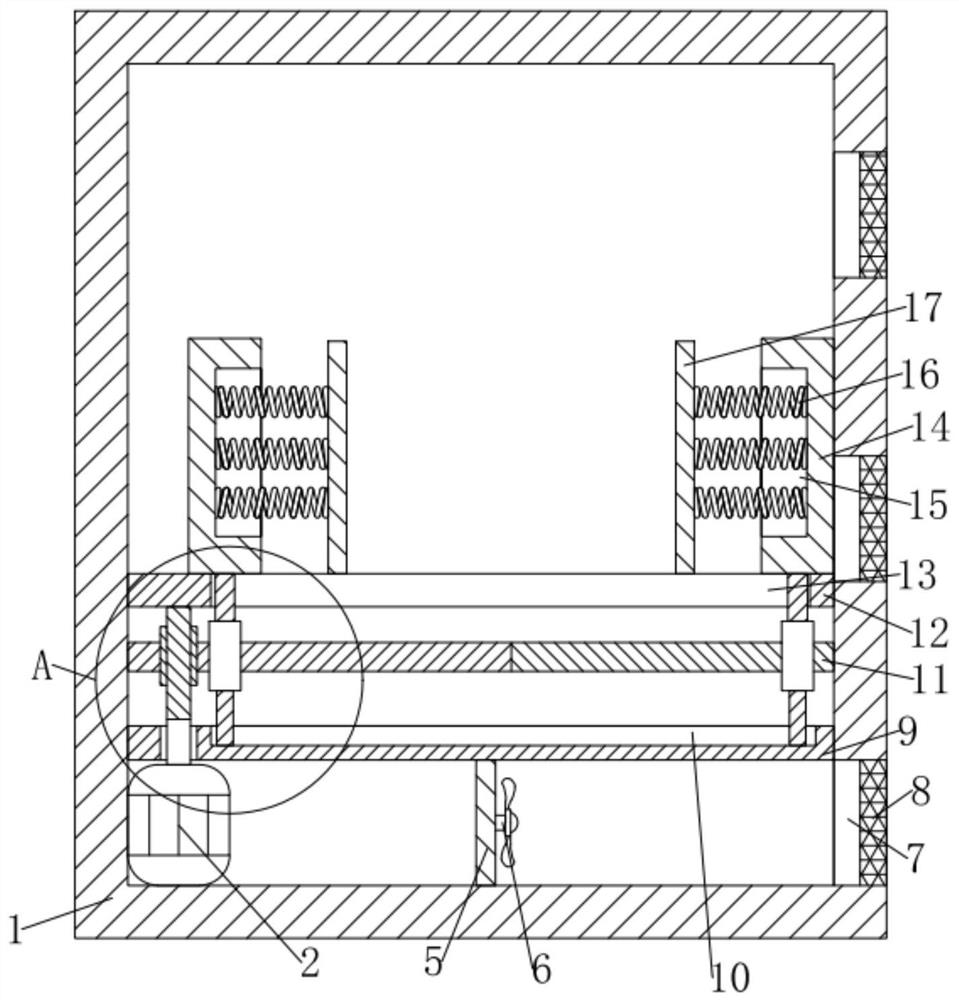

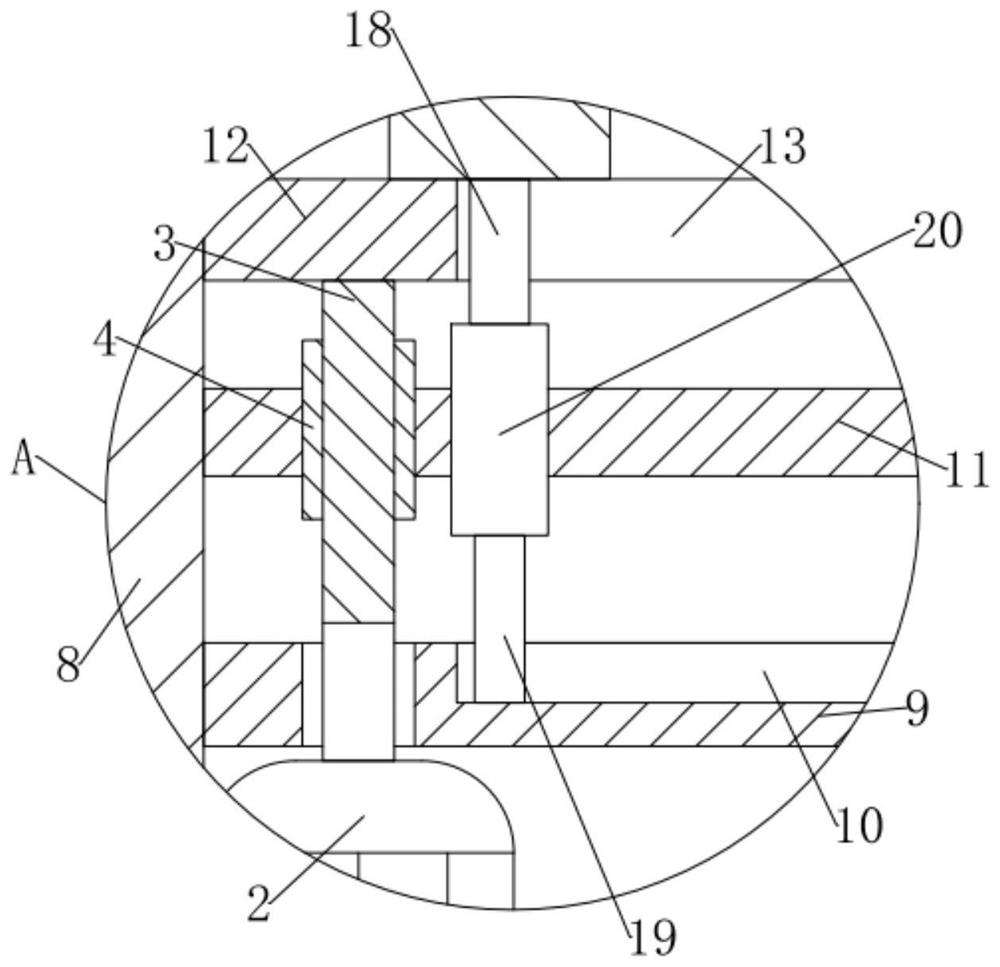

[0028] see Figure 1-3 , a clamping and fixing device for automobile welding, comprising a protection box 1, a first support plate 9 is fixedly connected between the left and right inner walls of the protection box 1, and a forward and reverse motor 2 is fixedly connected to the lower interior of the protection box 1, and the first The lower end of the support plate 9 is dug with a first installation hole, the output end of the forward and reverse motor 2 moves through the first installation hole, the output end of the forward and reverse motor 2 is fixedly connected with a worm 3, and the left and right inner walls of the protection box 1 rotate Connected with a threaded rod 11, the surface of the threaded rod 11 is fixedly connected with the worm gear 4, the worm 3 and the worm gear 4 are engaged, the threaded rod 11 is located on the top of the first support plate 9, and the surface of the threaded rod 11 is threaded with two nuts 20, The upper ends of the two nuts 20 are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com