Rotary jig device of hydraulic pump assembly machine and jig rotating method

A technology of hydraulic pump and assembly machine, applied in the field of rotating fixture device, can solve the problems of affecting assembly accuracy, easy displacement of hydraulic pump, affecting sealing performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

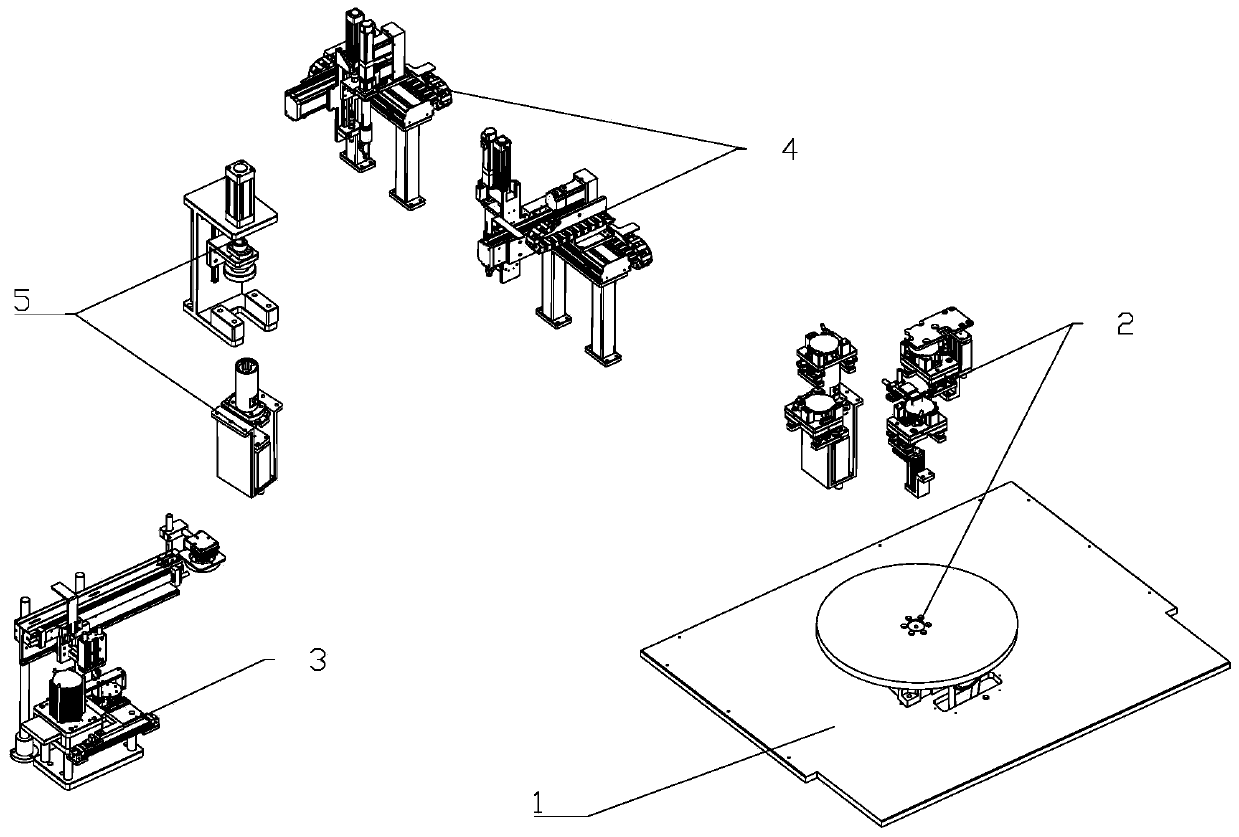

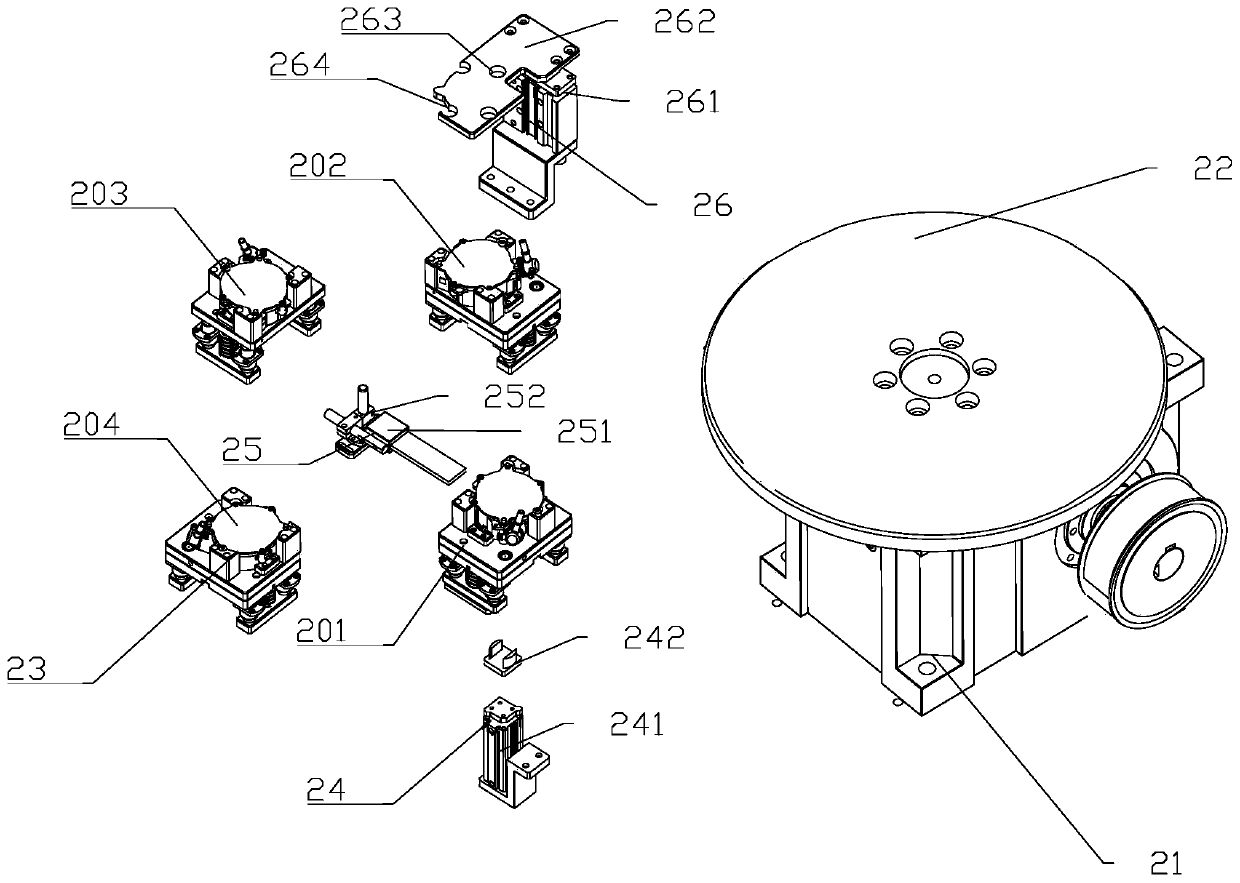

[0025] Such as figure 1 As shown, a hydraulic pump assembly machine includes a frame 1 and a rotating fixture device 2 installed on the frame 1, a pump cover feeding device 3, a screw locking device 4 and a sealing detection device 5; The jig device 2 is arranged at the center of the frame, and the pump cover feeding device 3, the locking screw device 4 and the seal detection device 5 respectively correspond to a station of the rotating jig device 2, and the rotating jig device 2 is There are four stations, and the remaining one station is equipped with a loading and unloading device.

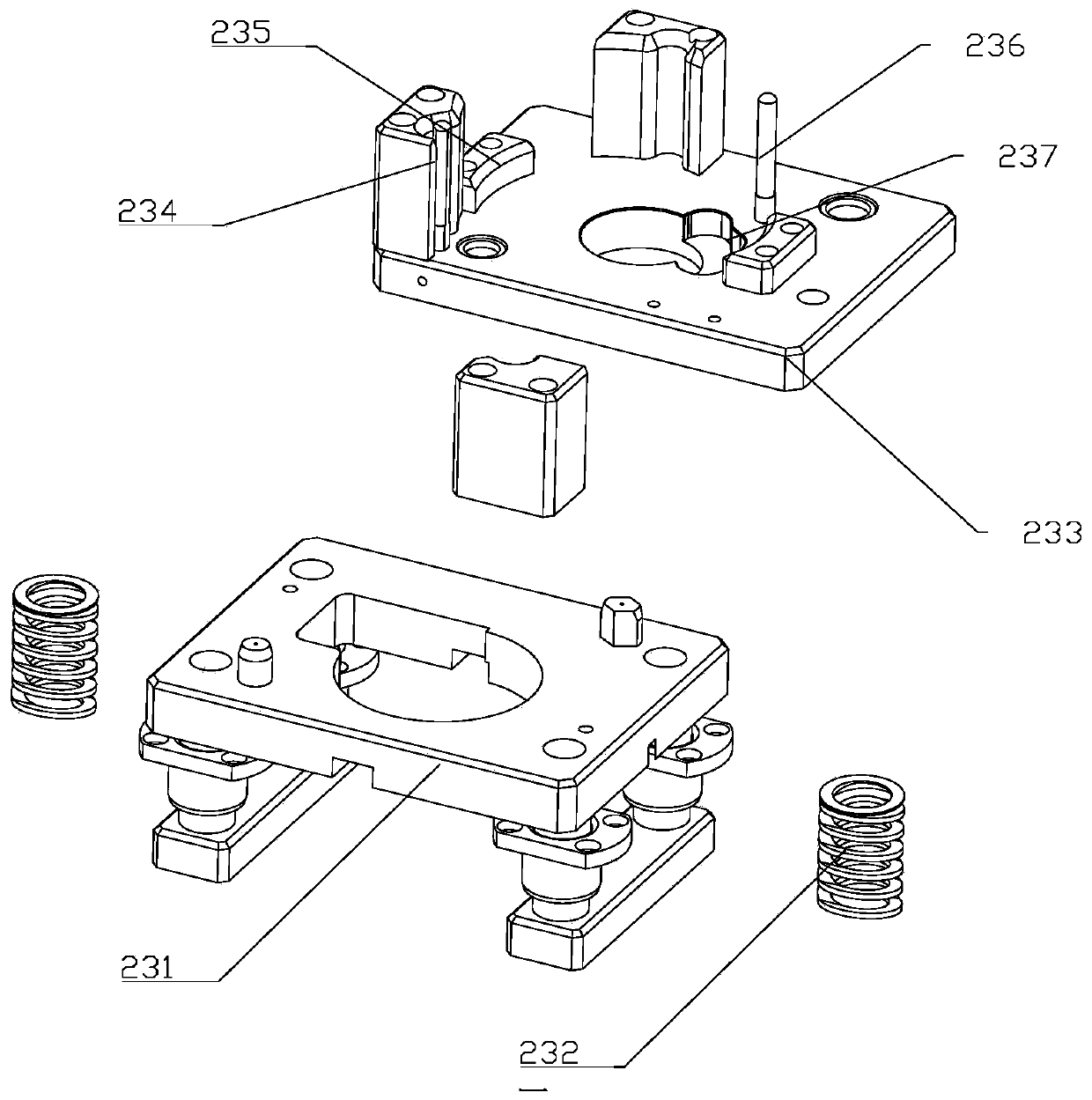

[0026] The rotating jig device 2 is used to set the hydraulic pump, and drives the hydraulic pump to circulate between various stations, and the pump cover feeding device 3 is used to separate the pump cover and transport it to the pump body. The screw locking device 4 described above is used for assembling screws into the pump body, and connects the pump cover and the pump body; the described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com