Three-way electricity guard wall structure and manufacturing method thereof

A manufacturing method and technology of anti-electricity wall, applied in lighting and heating equipment, fluid heaters and other directions, can solve the problems of difficult to guarantee insulation, water leakage, large water flow resistance, etc., to ensure absolute waterproofness, uniform wall thickness, The effect of water flow improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] It should be noted that the following "left" and "right" are only for better description of the technical solution, rather than any limitation.

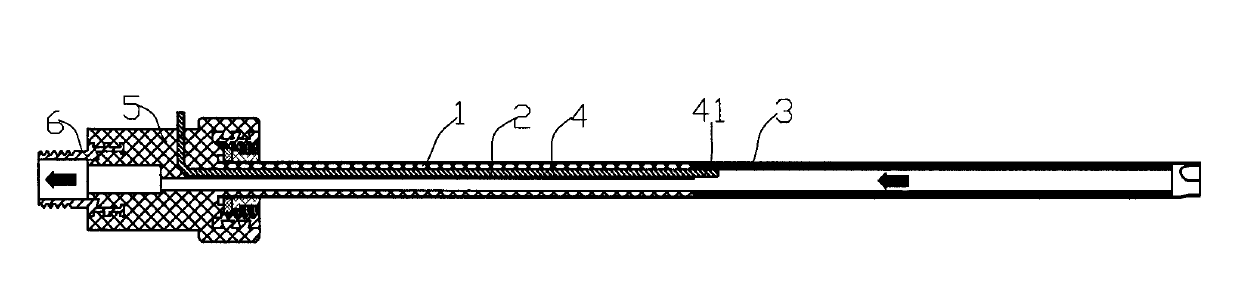

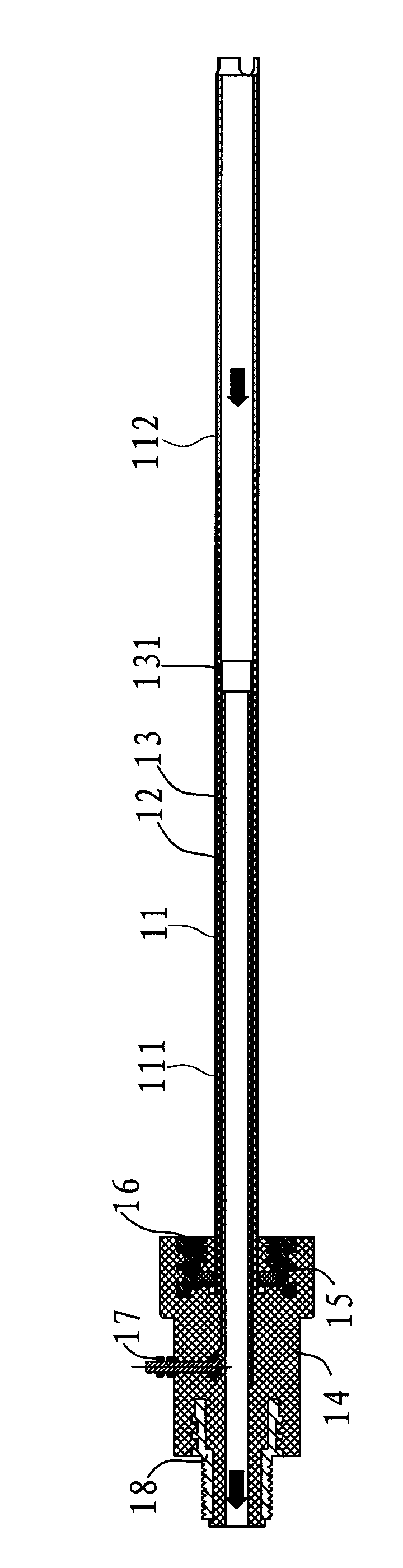

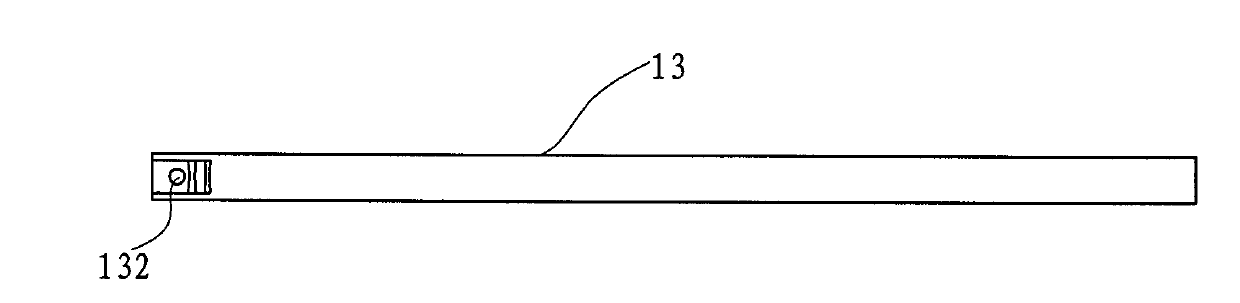

[0031] see figure 2 , a three-way anti-electric wall structure. Here, the anti-electric wall connected to the water outlet is taken as an example. The two water pipes 12 are buried with a grounding copper pipe 13 between the two water pipes, and the grounding copper pipe 13 is also connected in a socketed manner. The left ends of the first water pipe 11 and the second water pipe 12 all extend into the joint structure 14, and the connection between the first water pipe 11 and the joint structure 14 is provided with a plastic ring 15, which is used to fix and prevent the water heater from extending into the water heater. Deformation of electric wall. The outer periphery of the plastic ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com