Rear wheel camber angle adjusting device of automobile

A technology for adjusting devices and camber angles, which is applied to vehicle components, transportation and packaging, steering mechanisms, etc., can solve problems that affect the accurate positioning of the car, and eccentric bolts are easy to shake, so as to avoid sliding teeth, avoid deflection, and reduce frequency and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

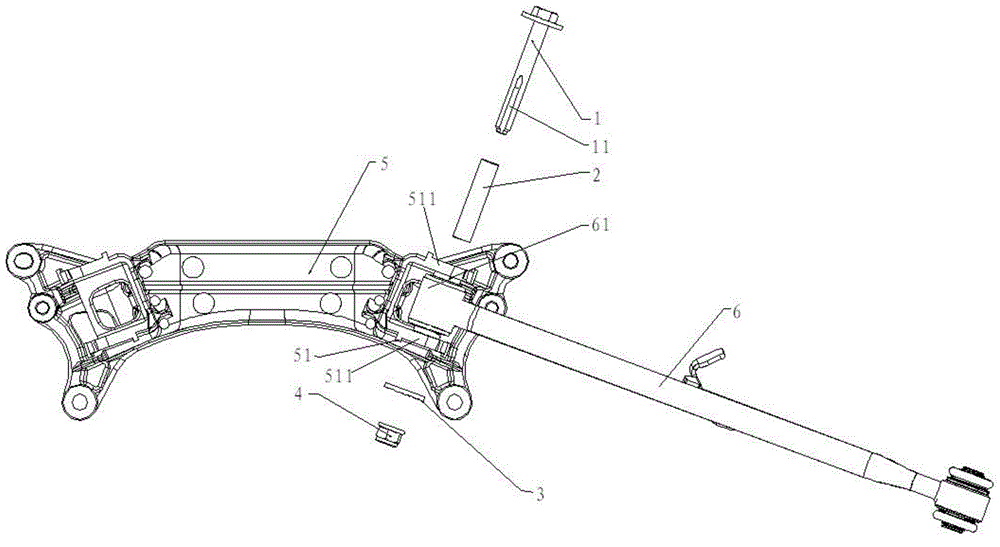

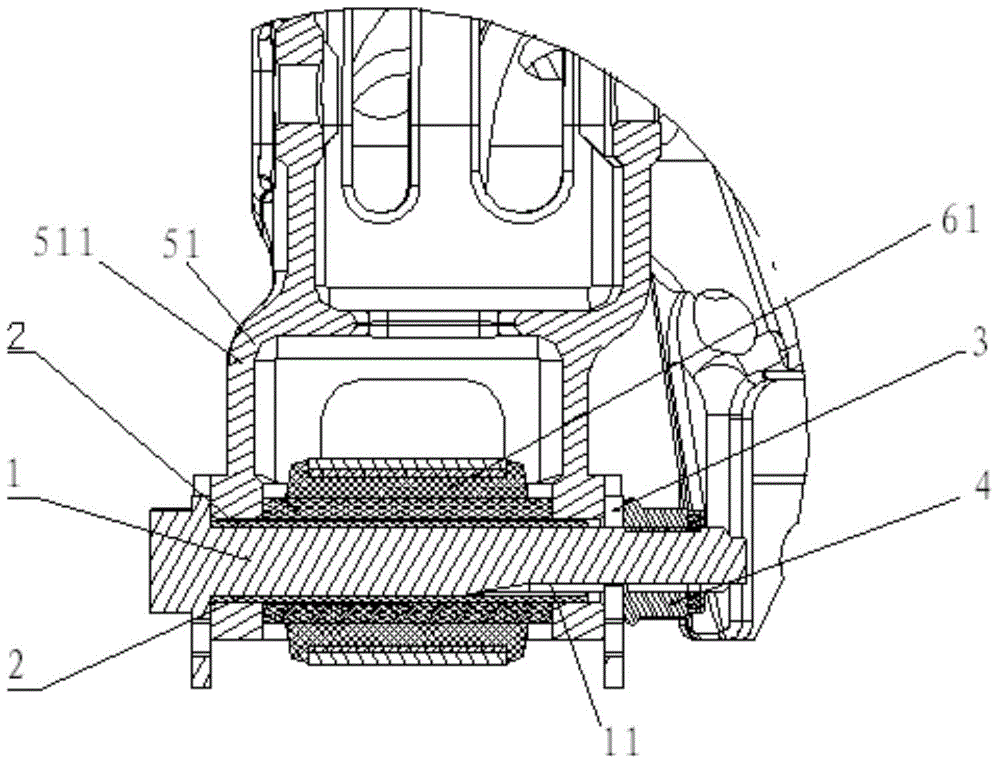

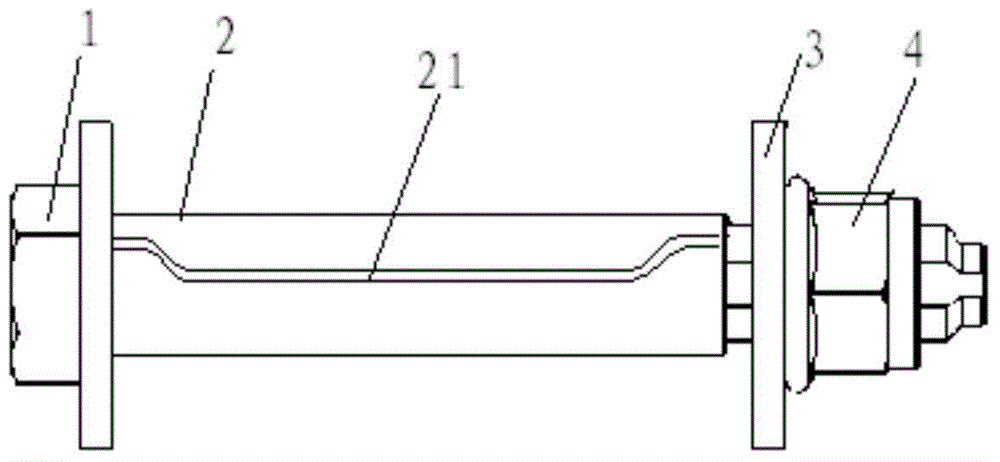

[0031] like figure 1 shown, see also figure 2 and image 3 , the embodiment of the present invention provides an automobile rear wheel camber adjustment device, said automobile rear wheel camber adjustment device comprising: eccentric bolt 1, elastic sleeve 2, eccentric washer 3 and lock nut 4, said eccentric The bolts 1 are sequentially passed through the two legs 511 of the lower swing arm mounting bracket 51, and the eccentric bolts 1 are also passed through the lower swing arm mounting head 61 between the two legs 511. The sleeve 2 is set on the eccentric bolt 1, and the elastic sleeve 2 is located between the eccentric bolt 1 and each of the legs 511, between the eccentric bolt 1 and the installation head 61 of the lower swing arm. Between, the eccentric washer 3 and the lock nut 4 are both sleeved on the eccentric bolt 1, and the lock nut 4 is located outside the leg 511 near the tail of the eccentric bolt 1, so The eccentric washer 3 is arranged between the locking ...

Embodiment 2

[0036] like figure 1 shown, see also figure 2 and image 3Another embodiment of the present invention provides a rear wheel camber adjustment device for an automobile, which includes: an eccentric bolt 1, an elastic sleeve 2, an eccentric washer 3 and a lock nut 4, the The eccentric bolts 1 are sequentially threaded on the two legs 511 of the lower arm mounting bracket 51, and the eccentric bolts 1 are also threaded in the lower arm mounting head 61 between the two legs 511, so that The elastic sleeve 2 is sleeved on the eccentric bolt 1, and the elastic sleeve 2 is located between the eccentric bolt 1 and each of the legs 511, the eccentric bolt 1 and the installation head of the lower swing arm 61, the eccentric washer 3 and the lock nut 4 are set on the eccentric bolt 1, and the lock nut 4 is located outside the leg 511 near the tail of the eccentric bolt 1 , the eccentric washer 3 is arranged between the locking nut 4 and the leg 511 , and the elastic sleeve 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com