Self-tapping method for machine screw and self-tapping pre-manufactured hole of machine screw

A technology of prefabricating holes and screws, which can be used in motor vehicles, parts of lighting devices, road vehicles, etc., can solve problems such as inability to penetrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

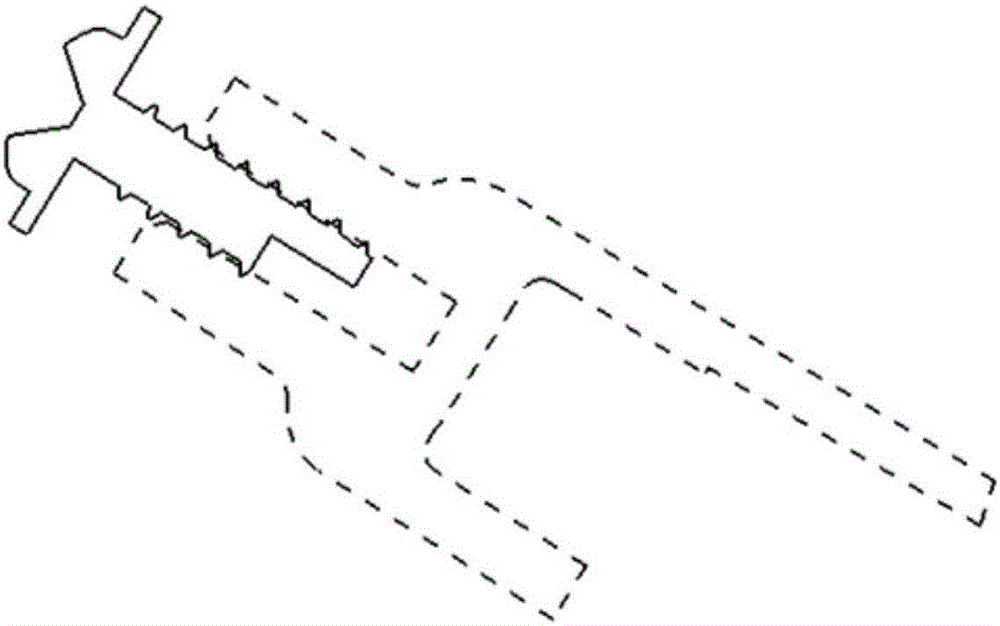

[0047] A self-tapping method for a machine screw, comprising: preset a prefabricated hole before the machine screw is tapped, and the prefabricated hole is a prefabricated hole with an inwardly convex "four petals" structure formed around the inner wall of a hole.

[0048] A prefabricated hole with a convex "four petals" structure is formed around the inner wall of the prefabricated hole mold. The prefabricated hole mold is a slider core-pulling directly outside.

[0049] Radius of the transition hole / radius of the prefabricated hole>1.1, the transition hole is the outermost hole at the top of the prefabricated hole, and the radius of the prefabricated hole is the outer radius of the screw thread. The ratio of the four-lobed orthographic projection area of the inwardly convex "four lobes" formed around the inner wall of the prefabricated hole / the orthographic projection area of the machine screw is between 0.4-0.5.

[0050] In addition, the inwardly convex "four petals" s...

Embodiment 2

[0052] Except for the following differences, others are the same as in embodiment 1, implementing the self-tapping of the mechanism screw:

[0053] The inward convex "four petals" structures formed around the inner wall of the prefabricated hole are symmetrically distributed at intervals of 90°, and the inwardly convex "four petals" structures formed around the inner wall of the prefabricated hole are asymptotically convex inward.

[0054] The ratio of the four-lobed orthographic projection area of the inwardly convex "four lobes" formed around the inner wall of the prefabricated hole / the orthographic projection area of the machine screw is 0.6.

[0055] According to the mechanism screw self-tapping method of the present invention, the screw teeth can be prevented from slipping by reducing the resistance of the mechanism screw while ensuring the meshing quantity of the screw teeth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com