Linear tester for testing plug-in boards

A testing machine and patch panel technology, which is applied in electrical connection testing, measuring electricity, measuring devices, etc., can solve problems such as large footprint, large position deviation, and bad alignment, and achieve accurate positioning, strong stability, and applicability. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

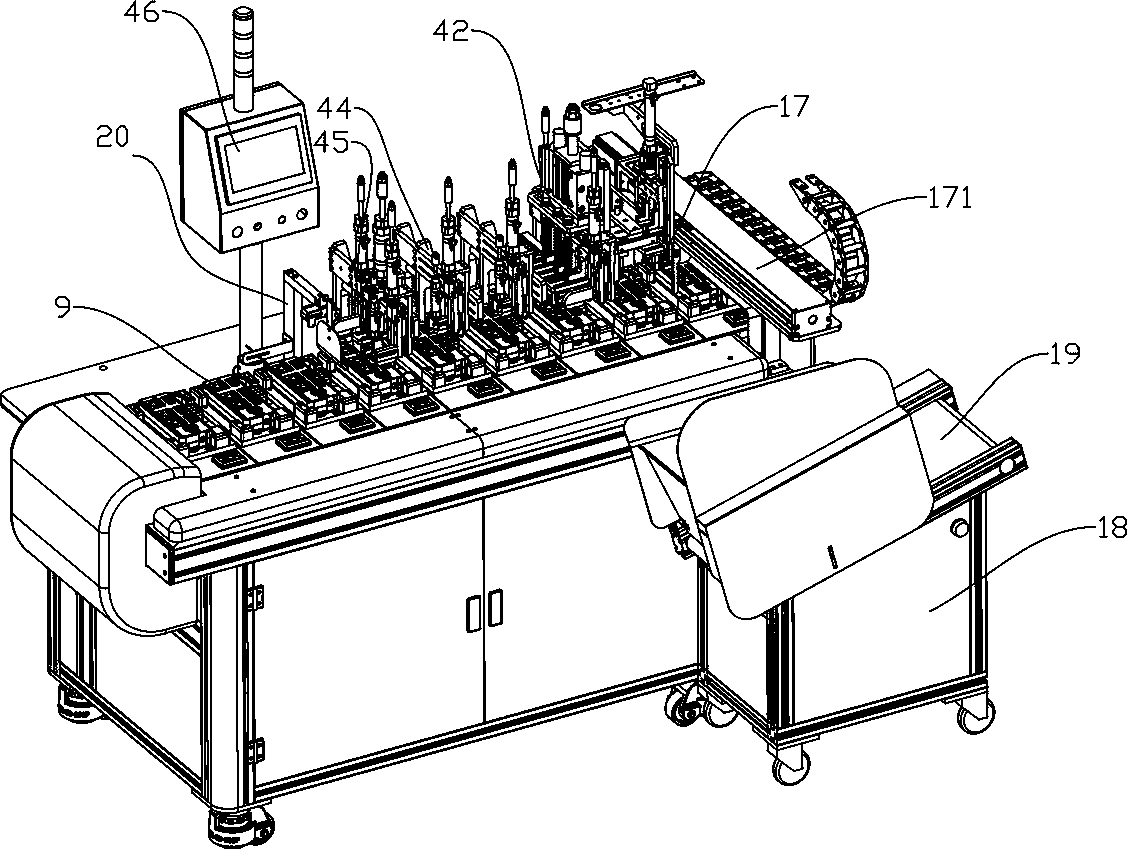

[0051] See figure 1 , figure 1 Shown is the linear testing machine in the present invention, which includes a main body, which is provided with a chain-structured circular conveying system, which can transport the plug-in boards 9 on the carrier one by one for multiple performance tests, and grasp them by the manipulator after the test is completed Put it into the material box; the main body is provided with an operating platform 46.

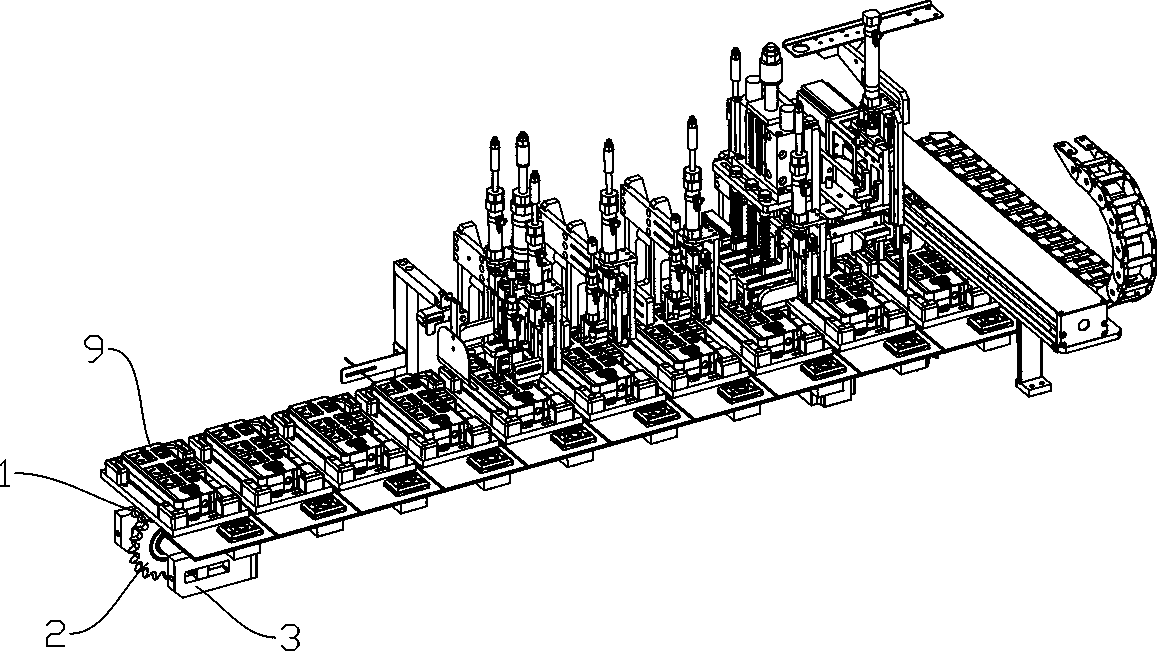

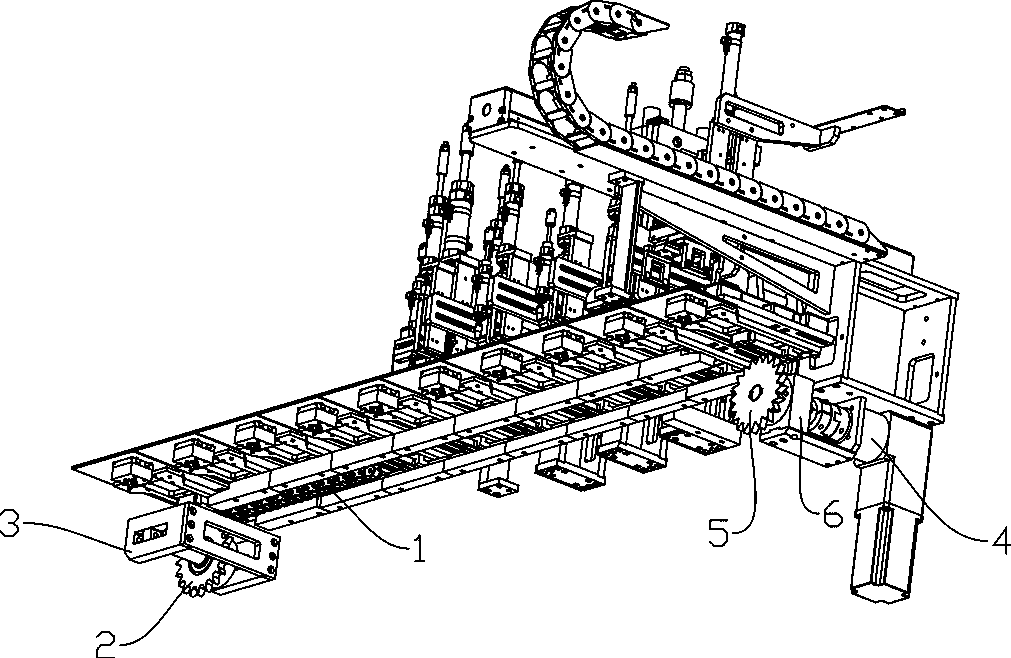

[0052] See Figure 2 to Figure 7 , a circular conveying system, including an endless chain 1 for conveying workpieces and a gear assembly that engages with the endless chain 1 and drives the endless chain 1 to rotate (the complete endless chain 1 is not shown in the figure, and the endless chain 1 is provided with There is a carrier mount 11 on which a carrier is fixed.

[0053] In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com