A reflective film for small-size backlight and a small-size backlight module

A technology of backlight module and reflective film, applied in the field of reflective film, can solve the problems of reflective film affecting backlight display, high cost, high requirements, etc., and achieve the effects of reducing uneven brightness, improving reflectivity, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

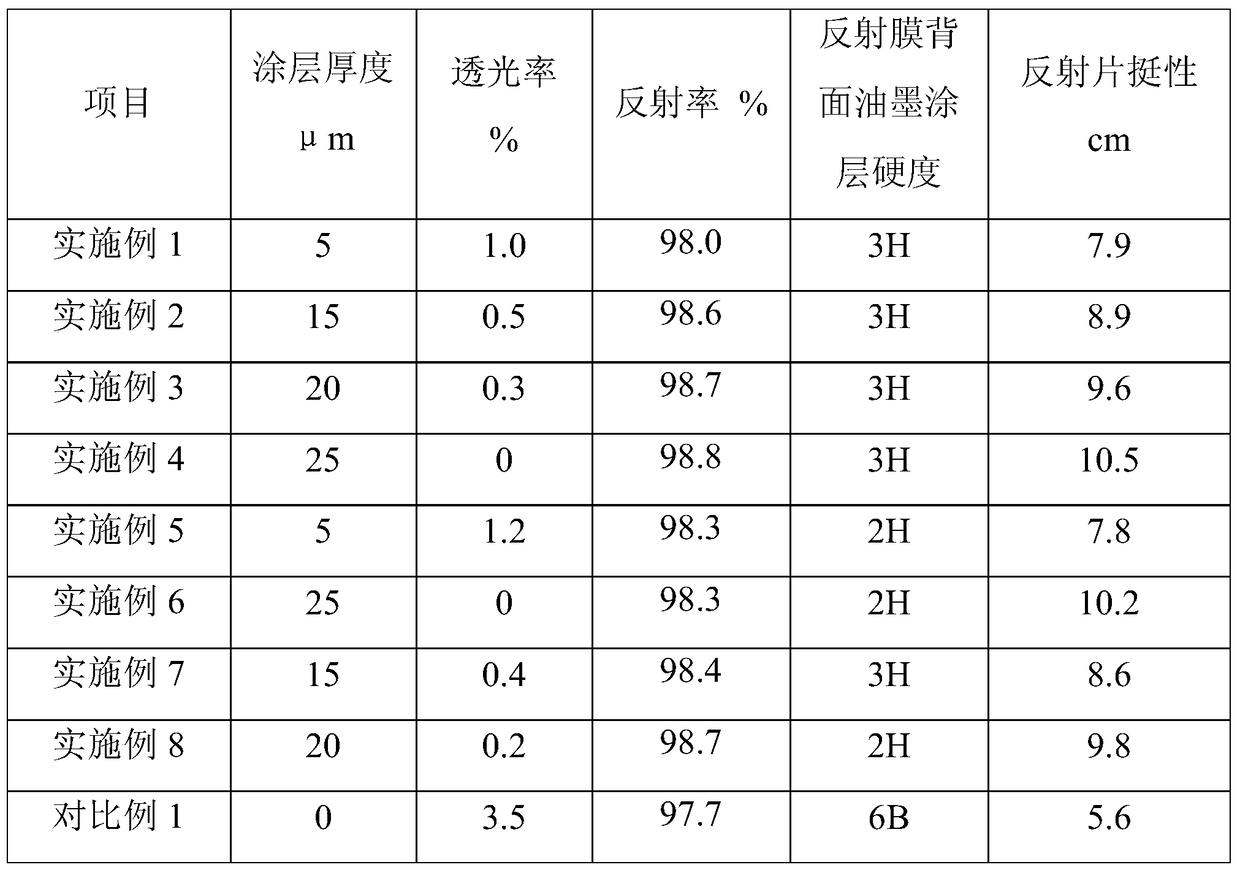

Embodiment 1

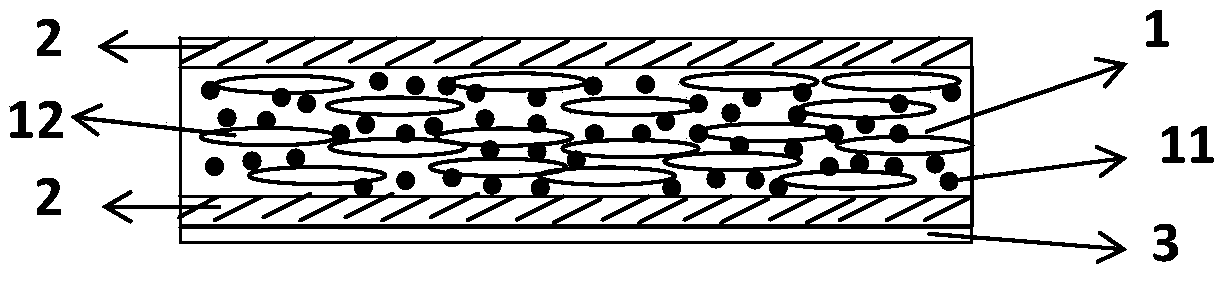

[0054] The invention provides a reflective film for small size backlight. The reflective film comprises a reflective film substrate and a white ink coating, and the white ink coating is coated on one side of the substrate.

[0055] The thickness of the white ink coating is 5 μm.

[0056] The base material includes a main layer and auxiliary layers arranged on both sides of the main layer; the raw materials of the main layer include 75% PET, 15% polypropylene, and 10% titanium dioxide particles. The raw materials of the auxiliary layer include 94% PET, 2% SiO 2 , 4% ethoxylated alkylamines.

[0057] The base material is an ABA three-layer co-extruded structure, the main layer is a B layer, and the auxiliary layer is an A layer. The thickness ratio of the A layer and the B layer in the ABA three-layer co-extrusion structure is: A:B=10:100. The thickness of the main layer was 50 μm.

[0058] The average particle diameter of the titanium dioxide particles is 0.2 μm.

[0059] ...

Embodiment 2

[0066] The invention provides a reflective film for small size backlight. The reflective film comprises a reflective film substrate and a white ink coating, and the white ink coating is coated on one side of the substrate.

[0067] The thickness of the white ink coating is 15 μm.

[0068] The base material includes a main layer and auxiliary layers arranged on both sides of the main layer; the raw materials of the main layer include 78% PET, 12% polypropylene, and 10% titanium dioxide particles. The raw materials of the auxiliary layer include 93% PET, 2% SiO 2 , 5% ethoxylated alkylamines.

[0069] The base material is an ABA three-layer co-extruded structure, the main layer is a B layer, and the auxiliary layer is an A layer. The thickness ratio of the A layer and the B layer in the ABA three-layer co-extrusion structure is: A:B=10:100. The thickness of the main layer was 150 μm.

[0070] The average particle diameter of the titanium dioxide particles is 0.5 μm.

[0071...

Embodiment 3

[0078] The invention provides a reflective film for small size backlight. The reflective film comprises a reflective film substrate and a white ink coating, and the white ink coating is coated on one side of the substrate.

[0079] The thickness of the white ink coating is 20 μm.

[0080] The base material includes a main layer and auxiliary layers arranged on both sides of the main layer; the raw materials of the main layer include 75% PET, 13% polypropylene, and 12% titanium dioxide particles. The raw materials of the auxiliary layer include 94% PET, 2% SiO 2 , 4% ethoxylated alkylamines.

[0081] The base material is an ABA three-layer co-extruded structure, the main layer is a B layer, and the auxiliary layer is an A layer. The thickness ratio of the A layer and the B layer in the ABA three-layer co-extrusion structure is: A:B=10:100. The thickness of the main layer was 100 μm.

[0082] The average particle diameter of the titanium dioxide particles is 0.5 μm.

[0083...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com