Patents

Literature

33results about How to "Reduce manual processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

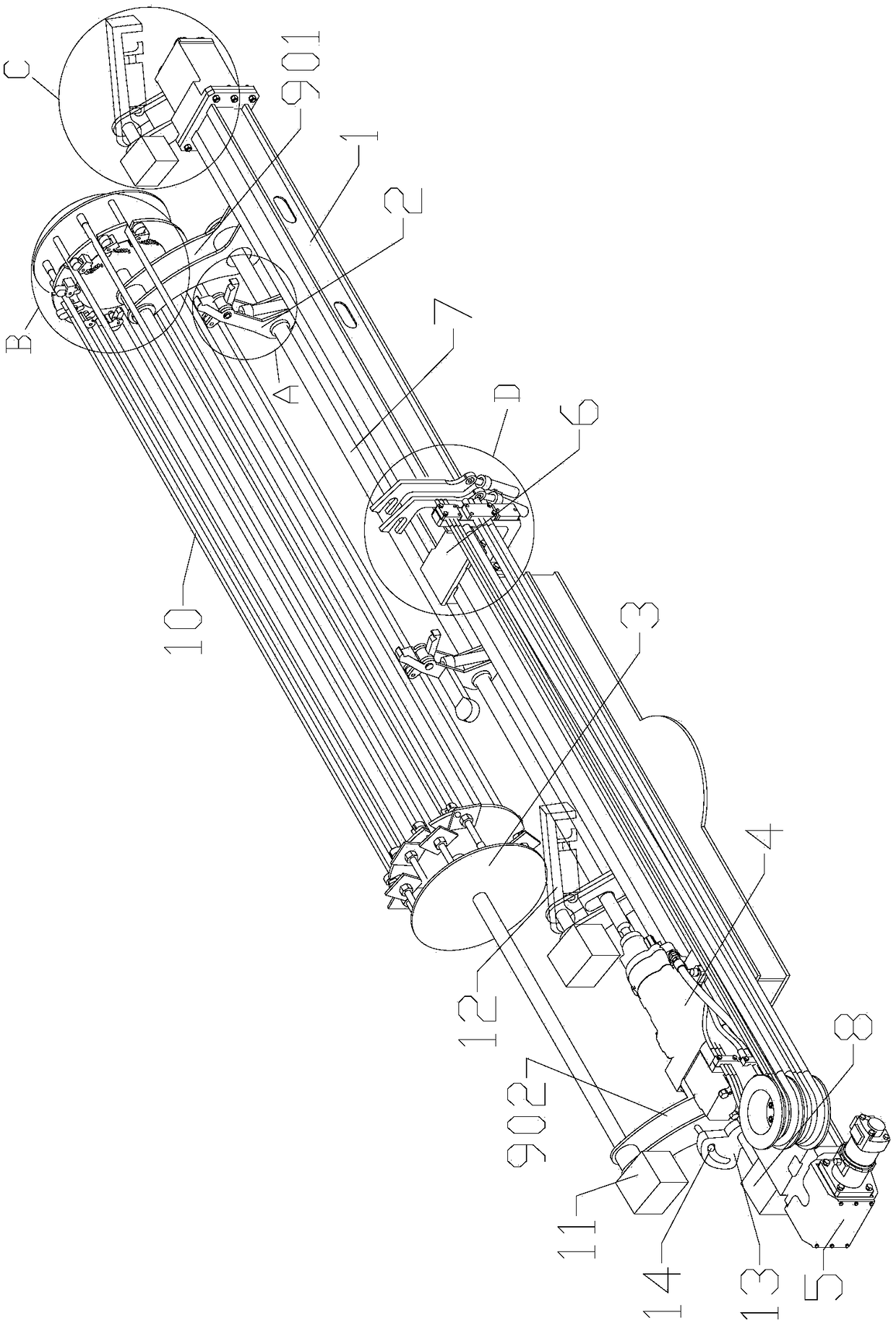

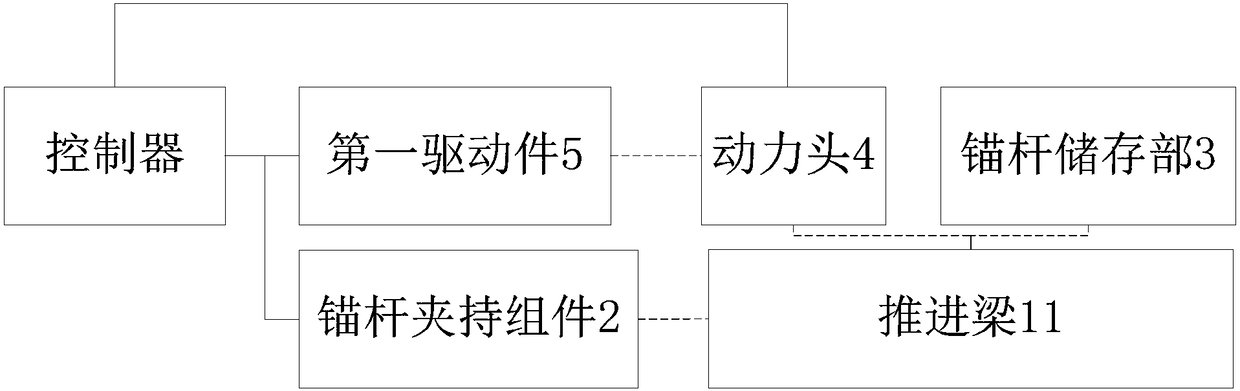

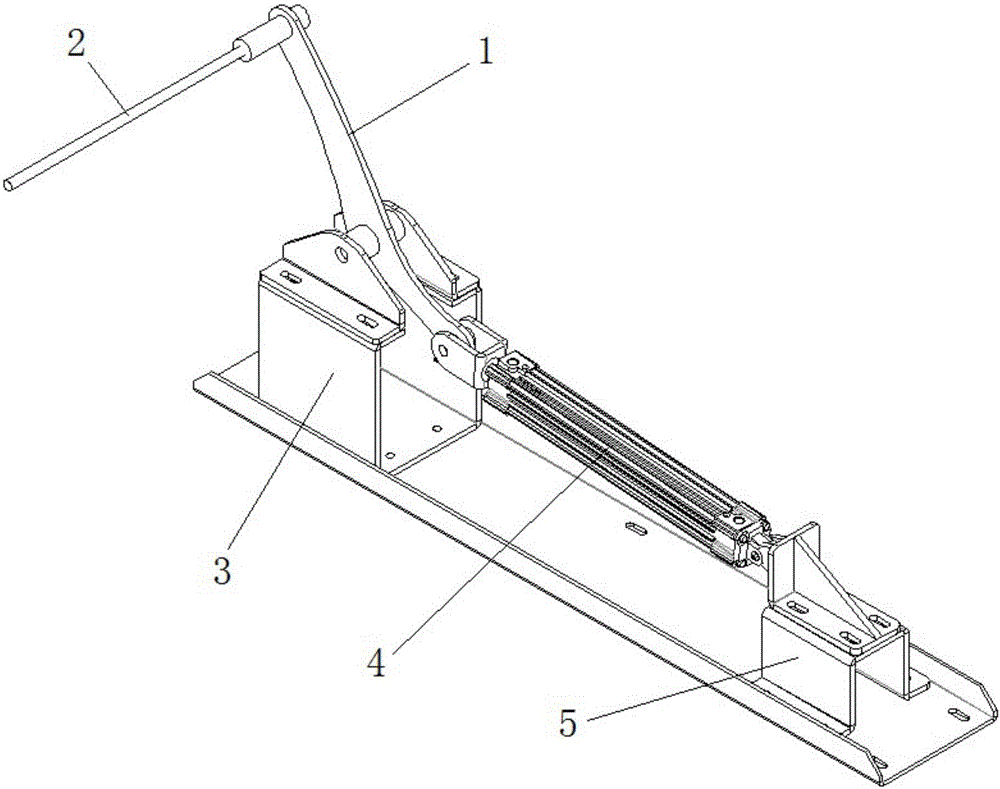

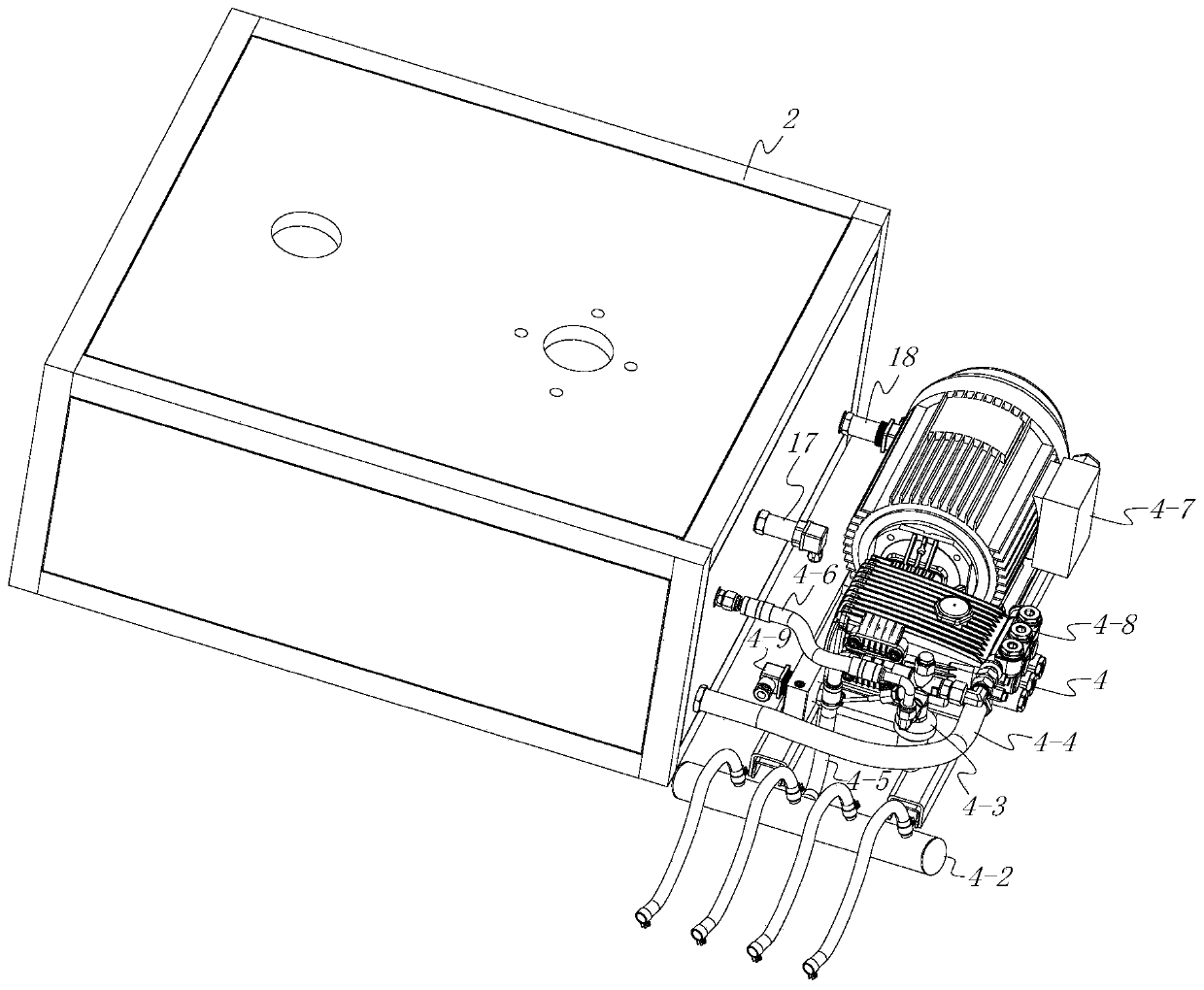

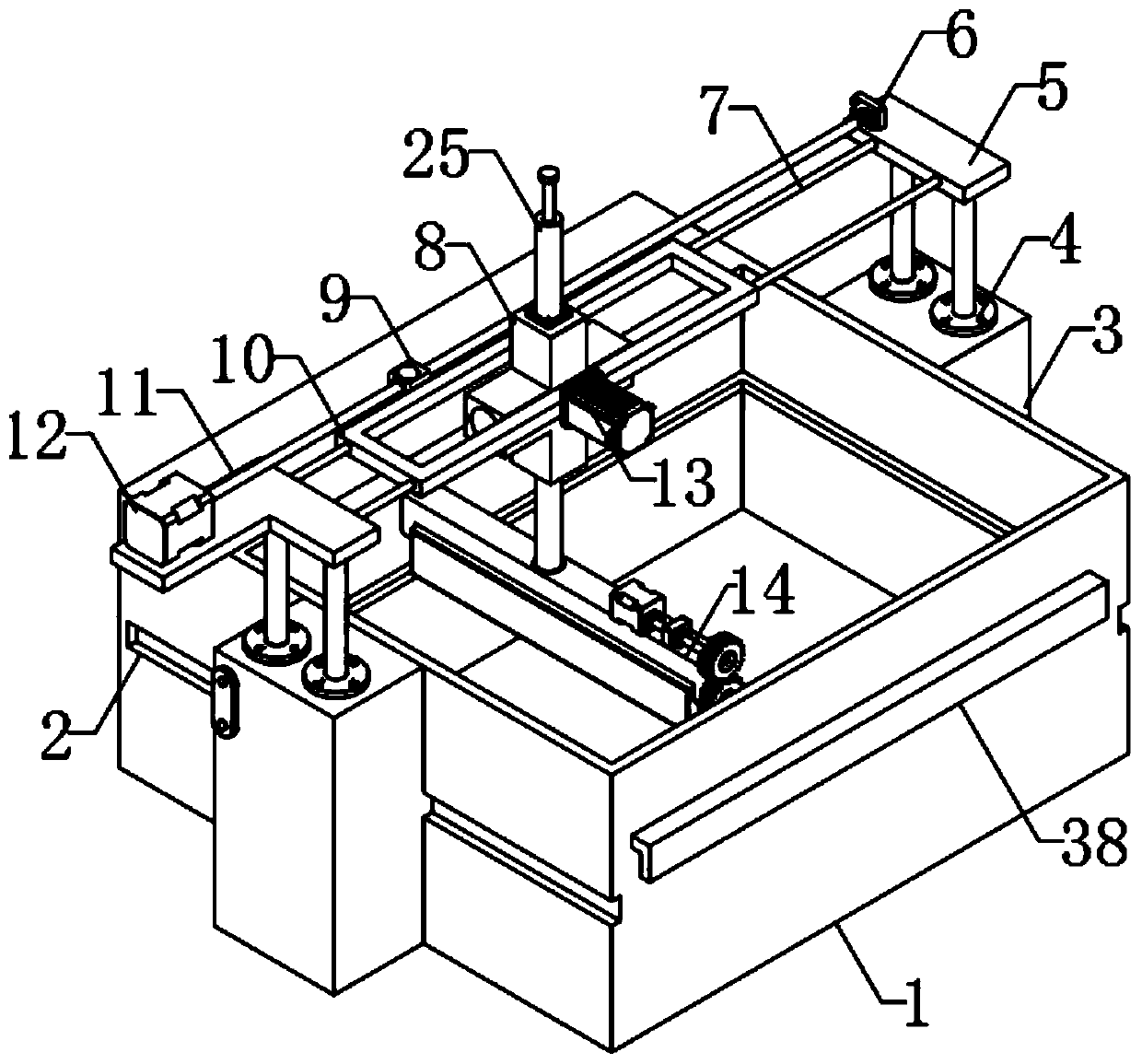

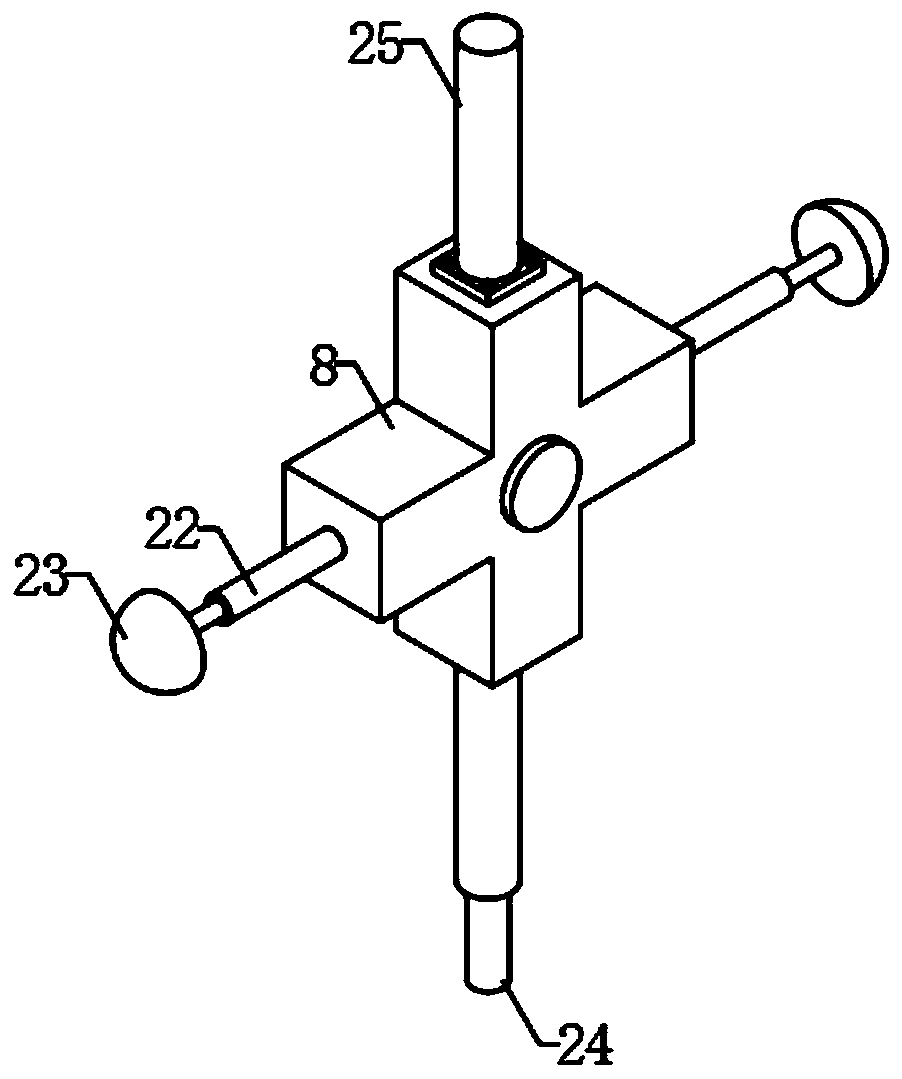

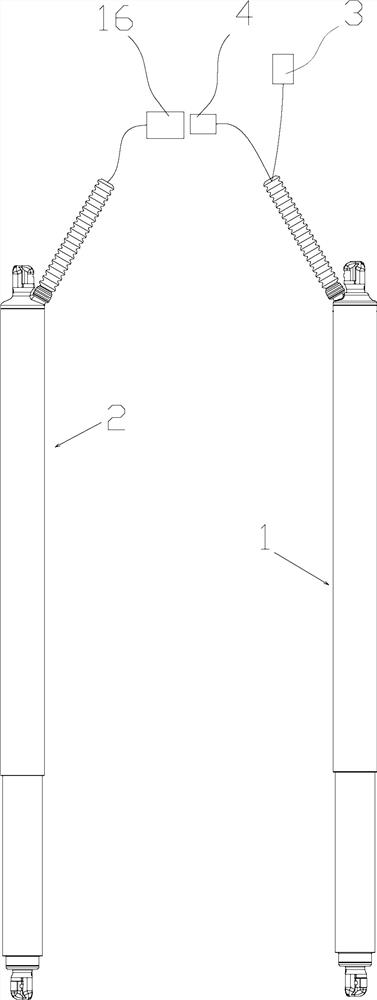

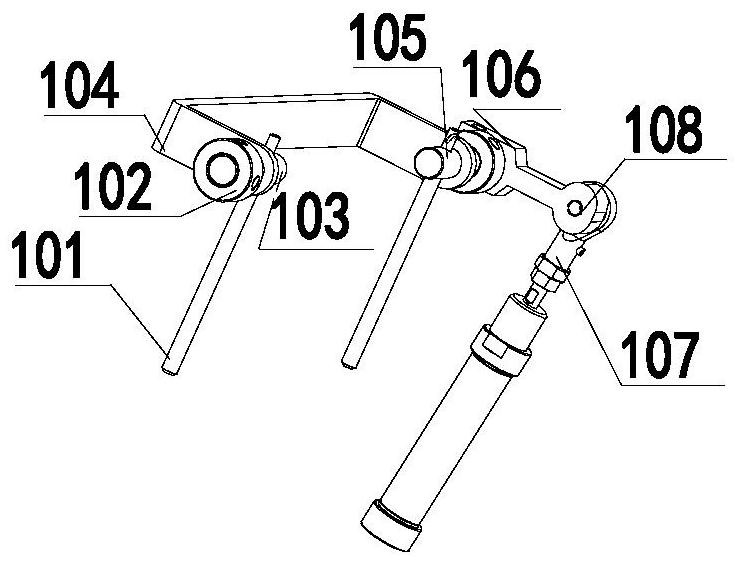

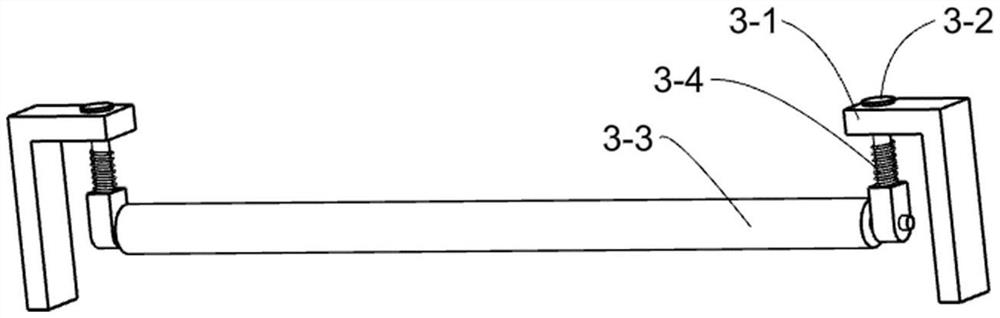

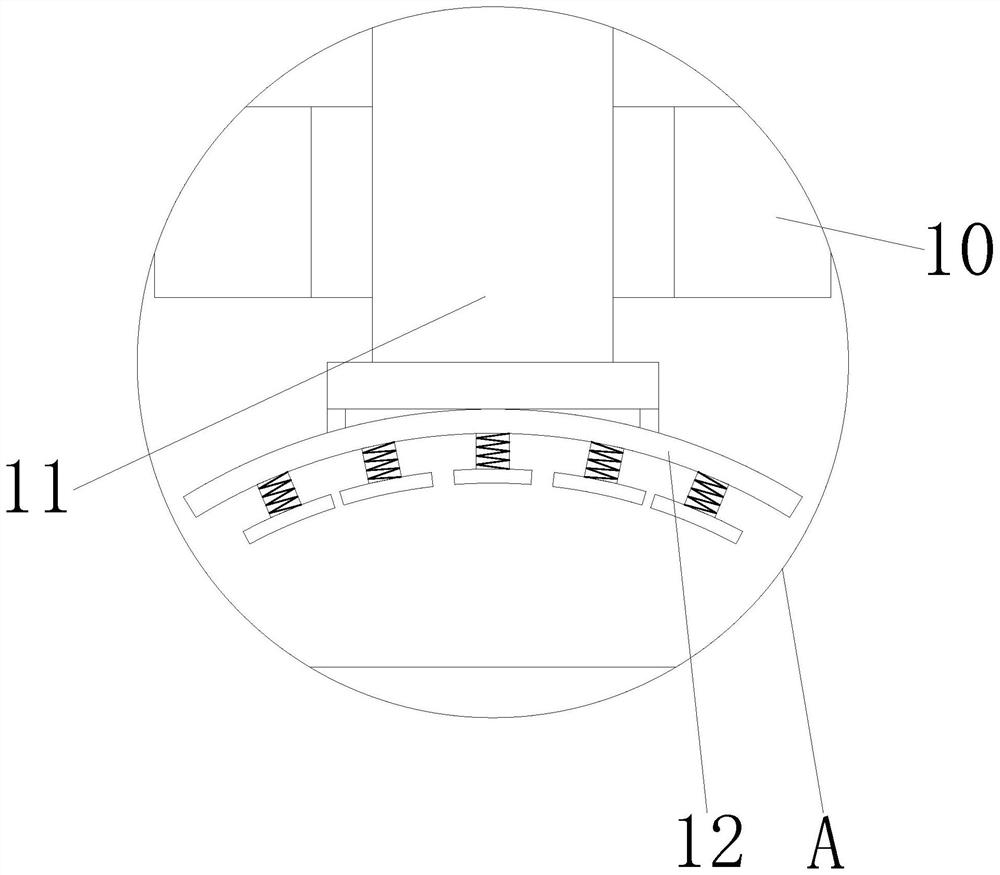

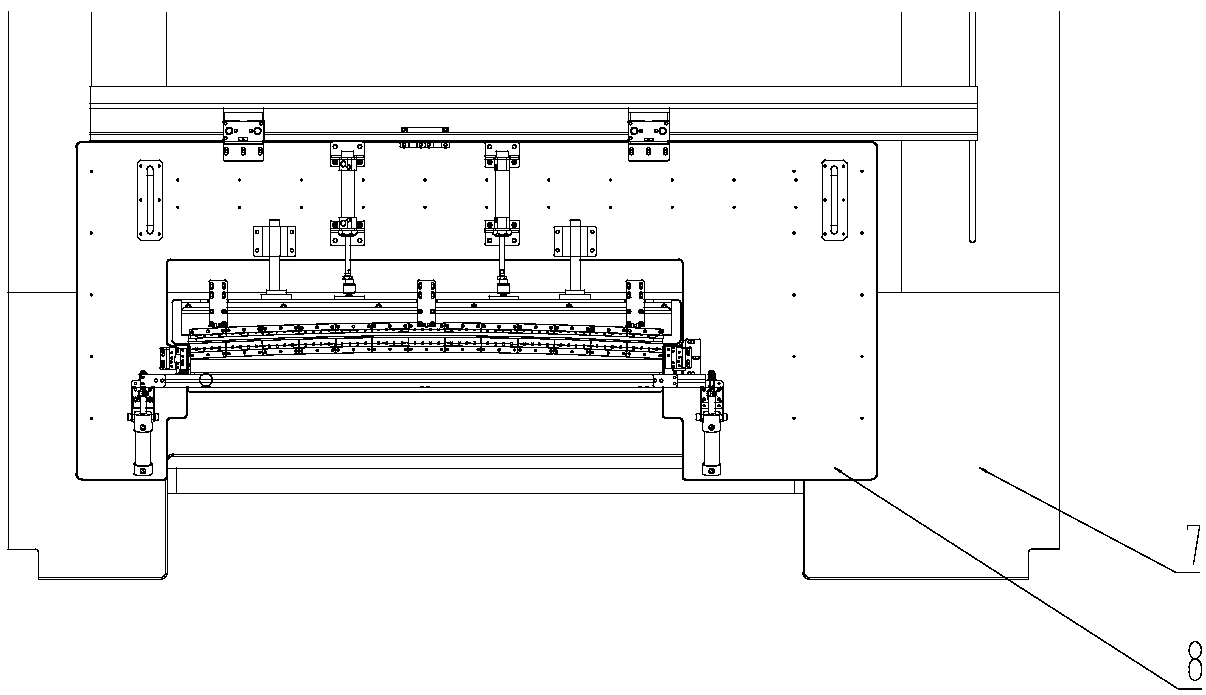

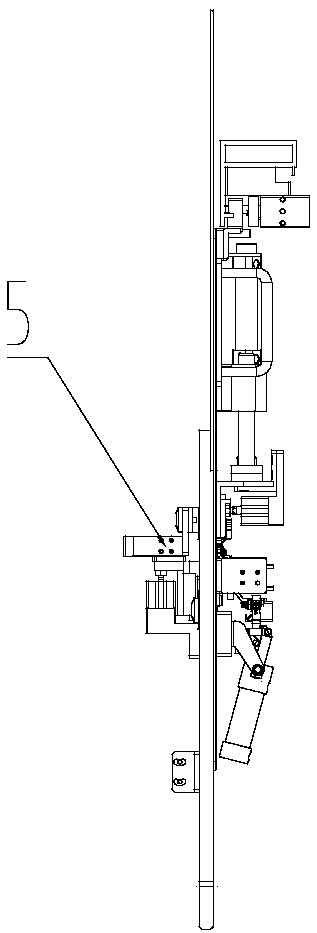

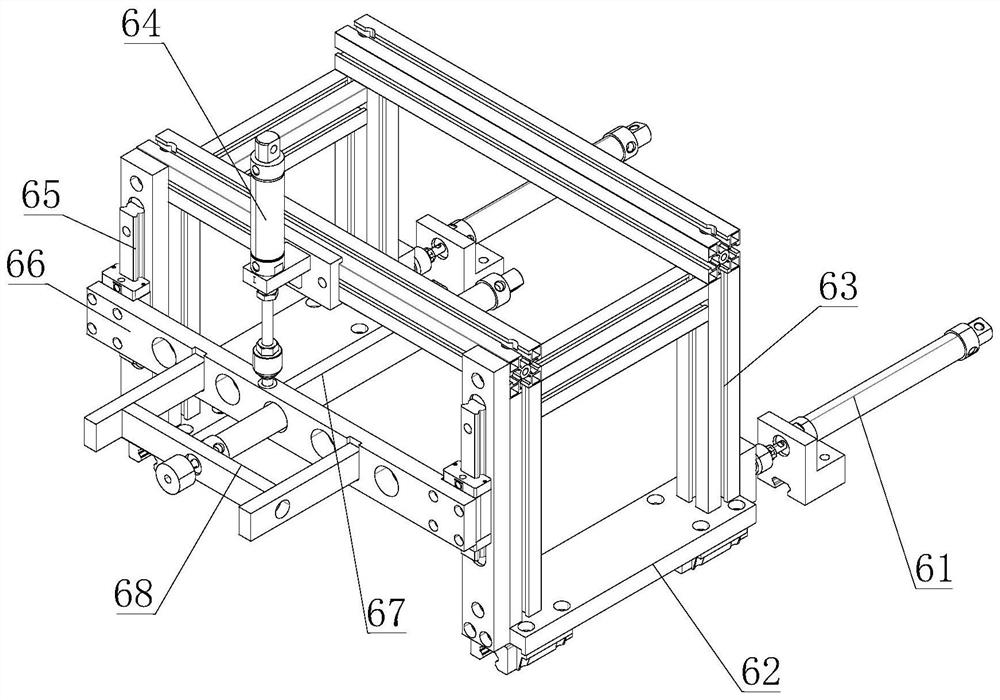

Anchor rod mounting device

ActiveCN108222987AReduce manual processesAccurate acquisitionDerricks/mastsWind energy generationEngineeringRock bolt

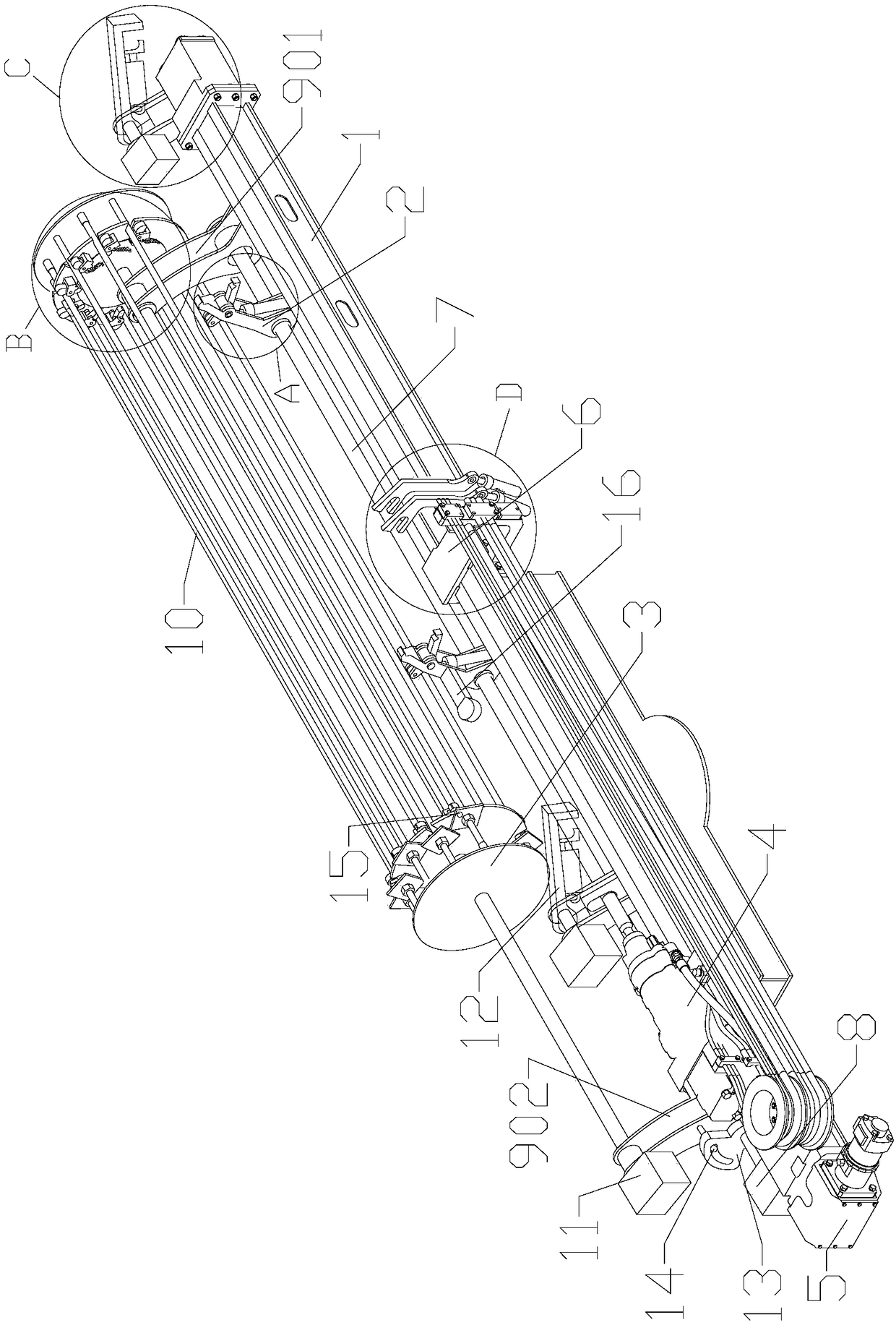

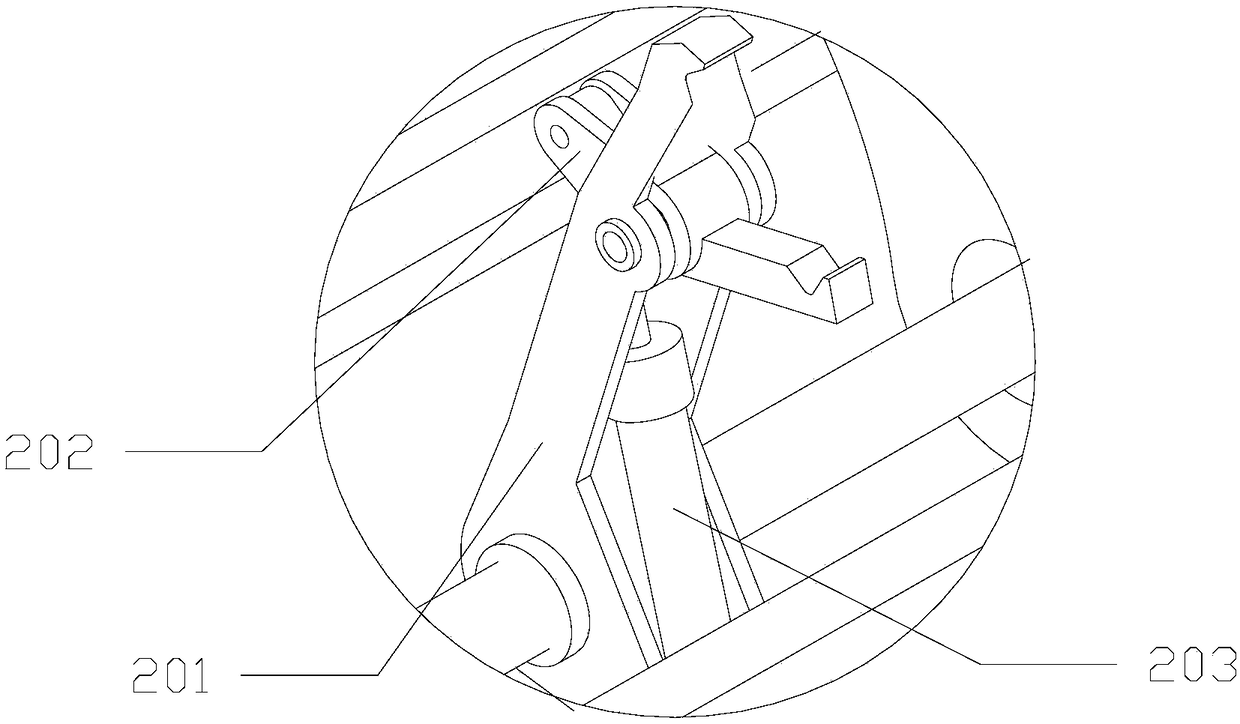

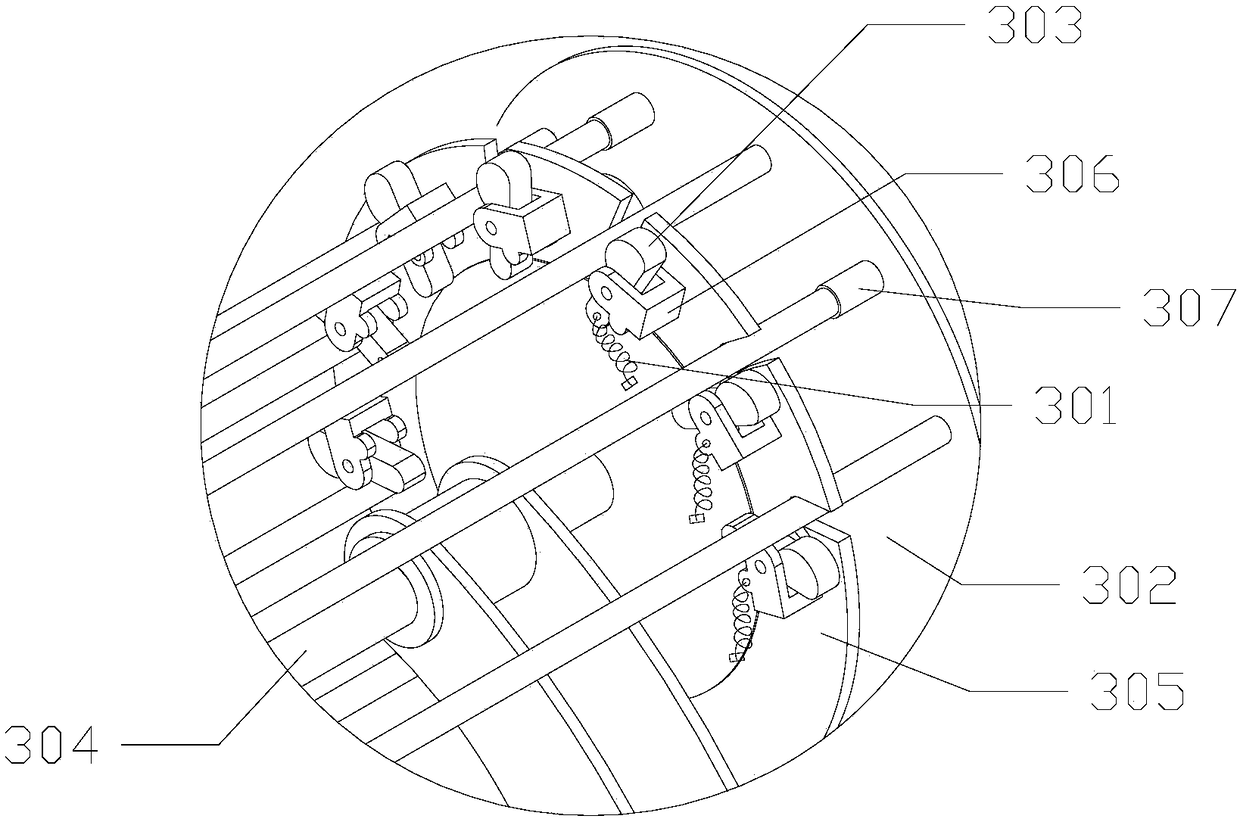

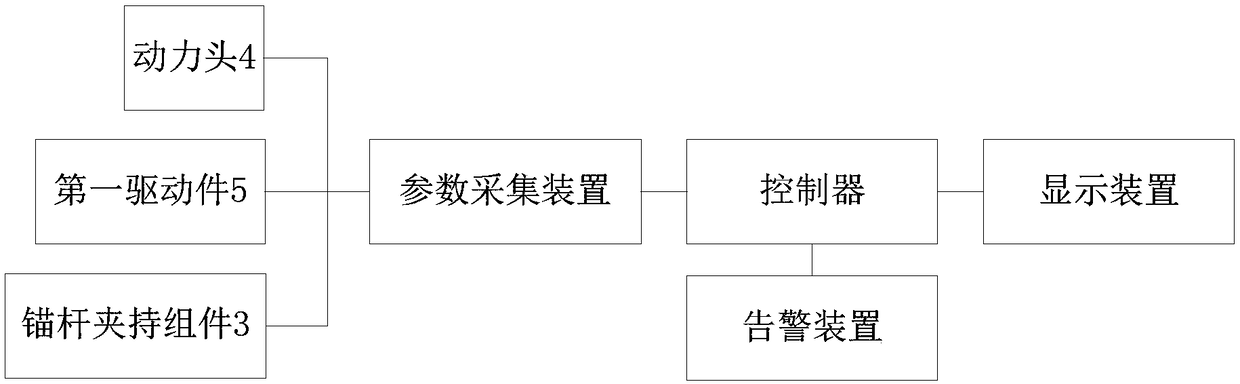

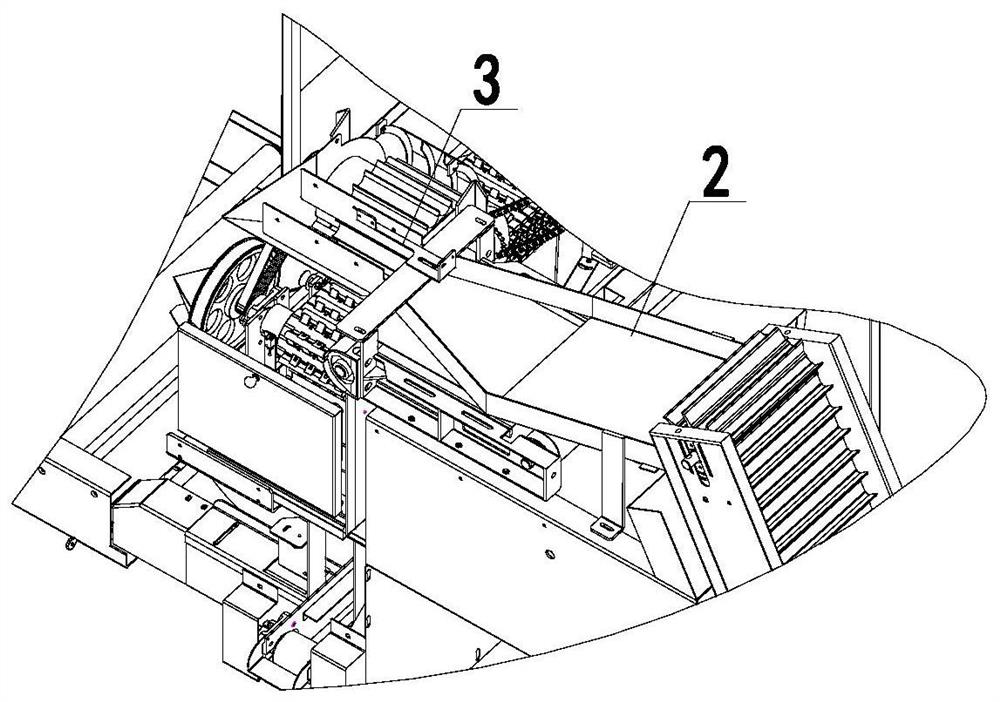

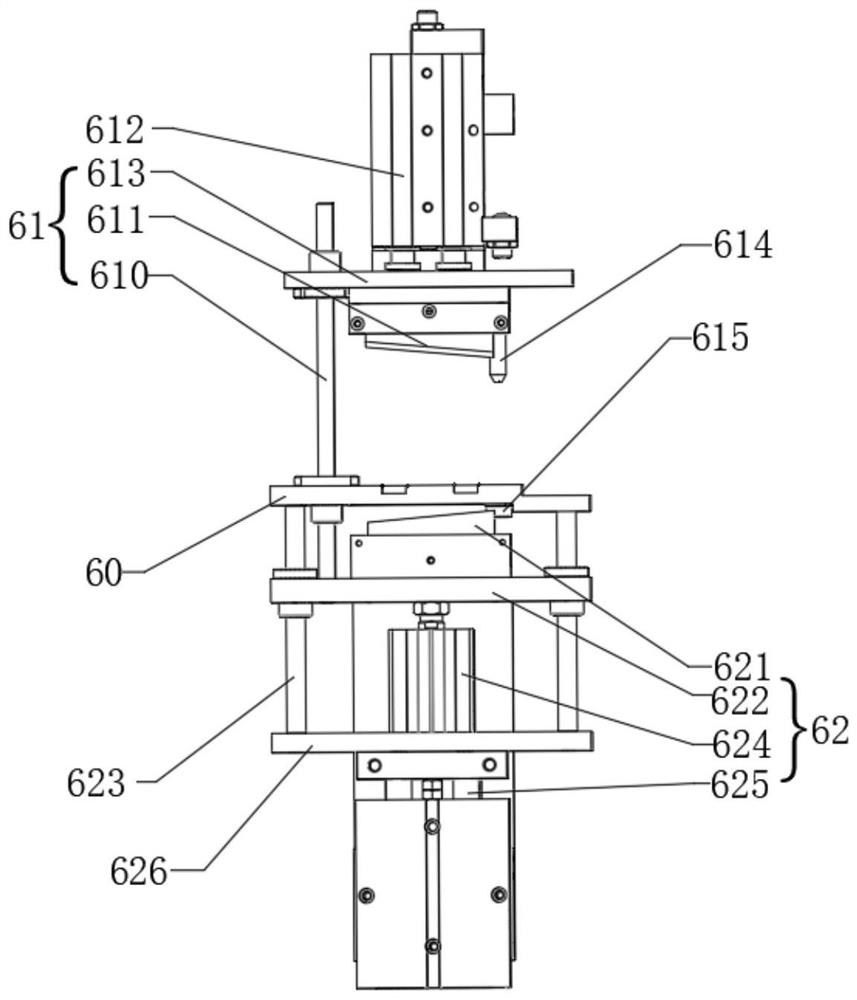

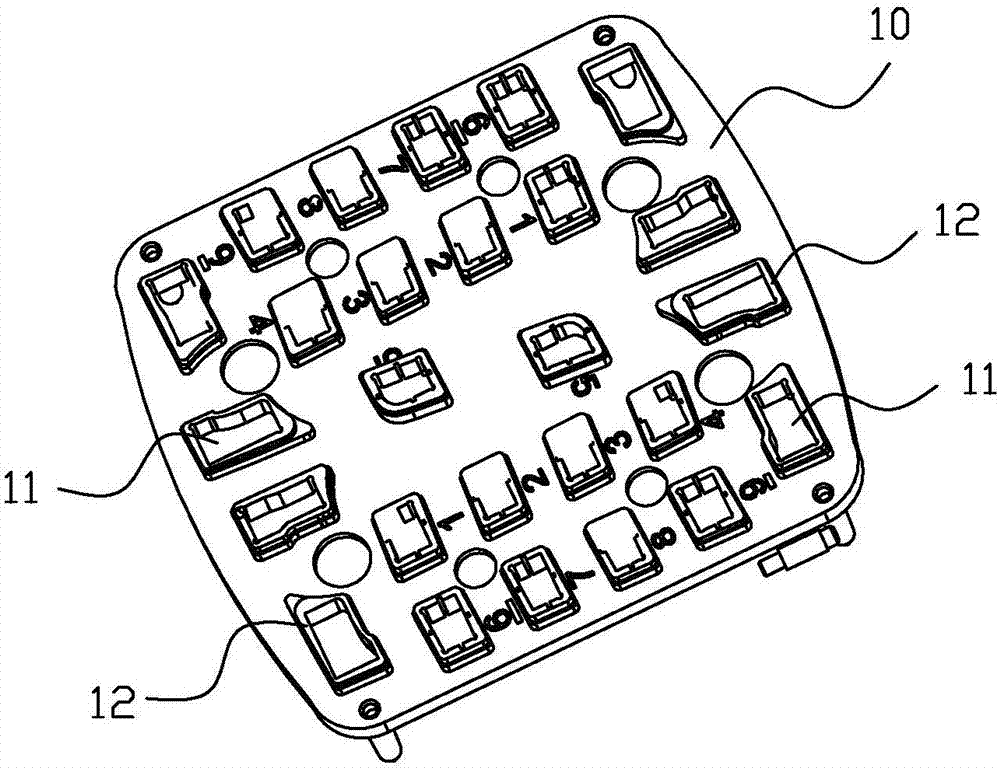

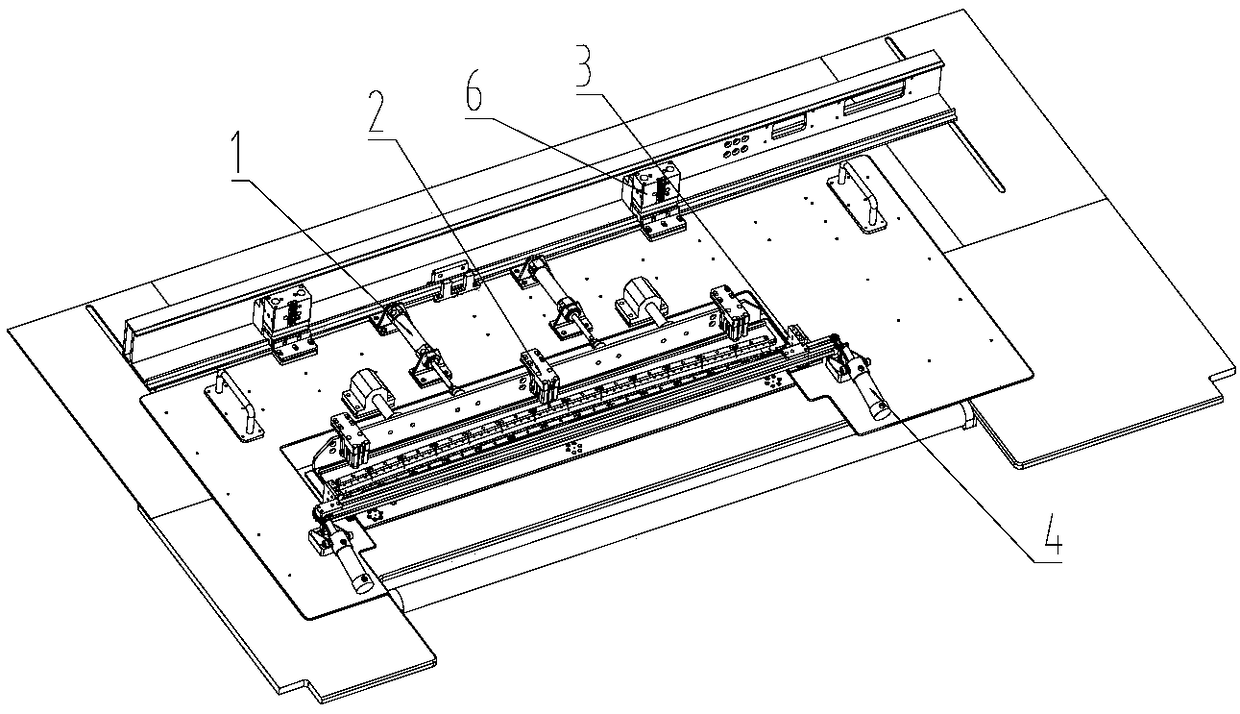

The invention relates to an anchor rod mounting device which comprises a thrusting beam, a power head, a first driving part, anchor rod storage portions and anchor rod clamping components. The power head is slidably mounted on the thrusting beam, the first driving part is used for driving the power head to slide along the thrusting beam, the anchor rod storage portions are fixed onto one side of the thrusting beam and used for placing a plurality of anchor rods, a recognizable label is arranged on each anchor rod, and the anchor rod clamping components are rotatably mounted on one side of thethrusting beam and used for placing the anchor rods of the anchor rod storage portions at the front end of the power head in a clamping manner, so that the anchor rods can be pushed by the power head.The anchor rod mounting device is integrated on a drilling machine, the anchor rod clamping components can place the anchor rods at the front end of the power head in a clamping manner after holes are drilled by the drilling machine, and the push force of the power head pushes the anchor rods to enter anchor rod holes. The recognizable label is arranged on each anchor rod, and information and mounting positions of the anchor rods can be accurately acquired when a reading device capable of recognizing the recognizable labels approaches to the anchor rods.

Owner:山西新能正源智能装备有限公司

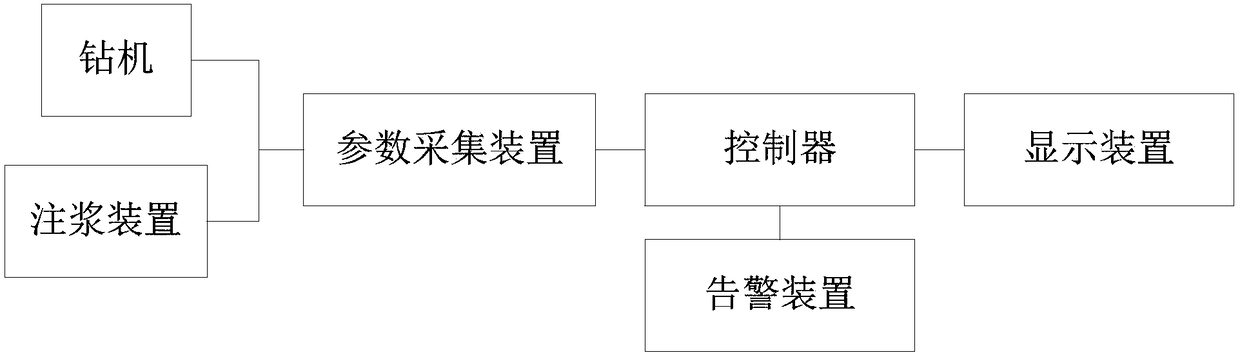

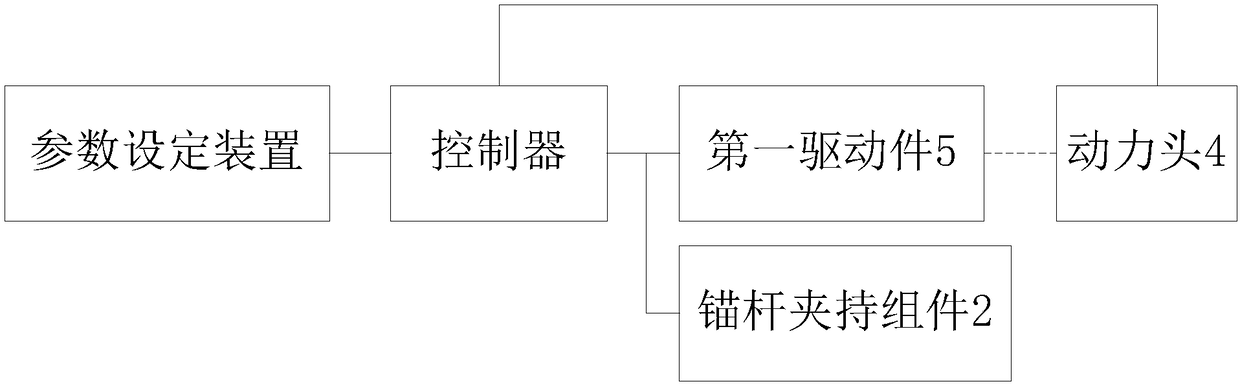

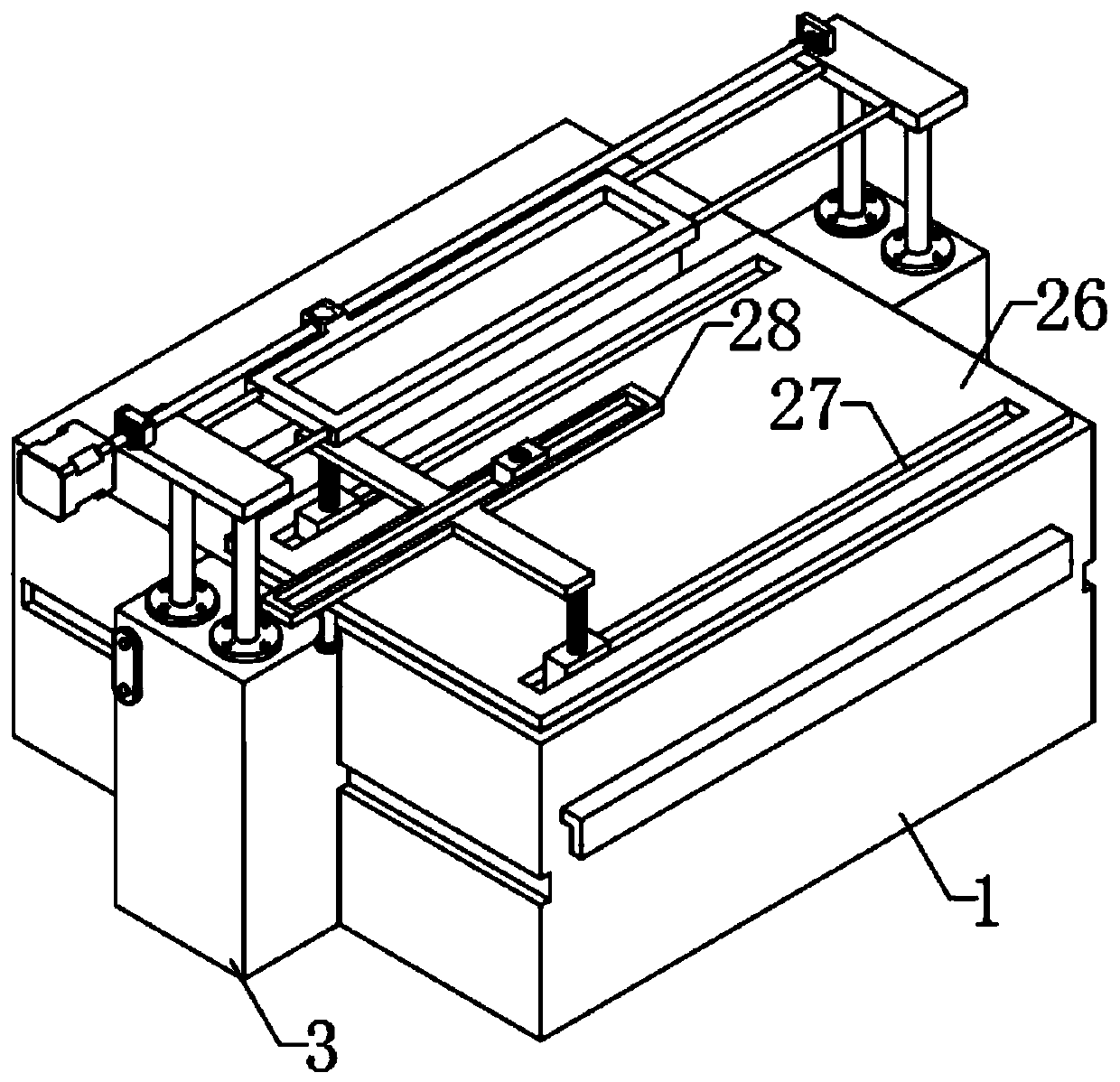

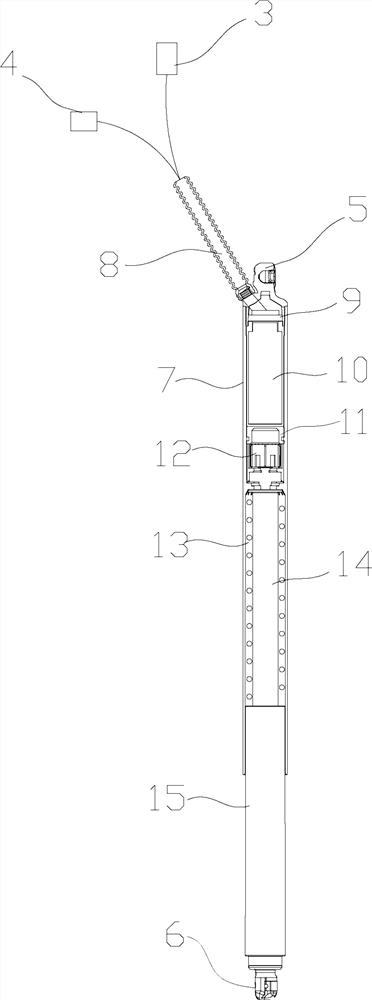

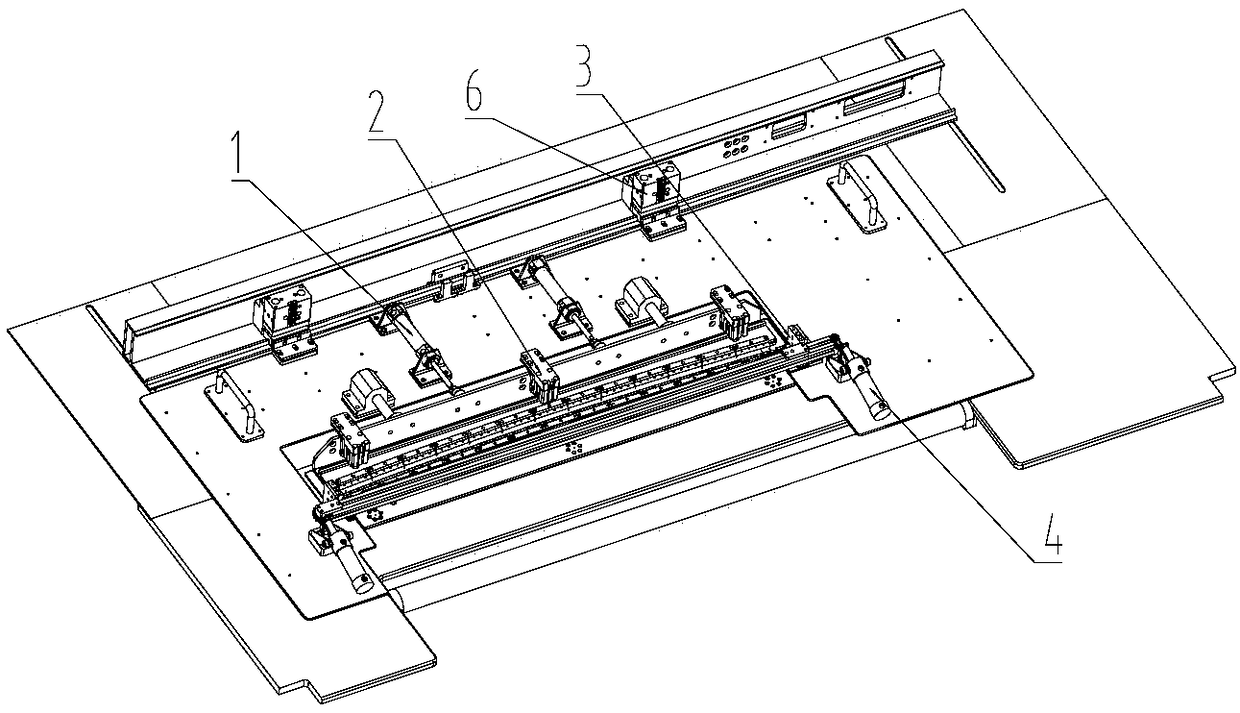

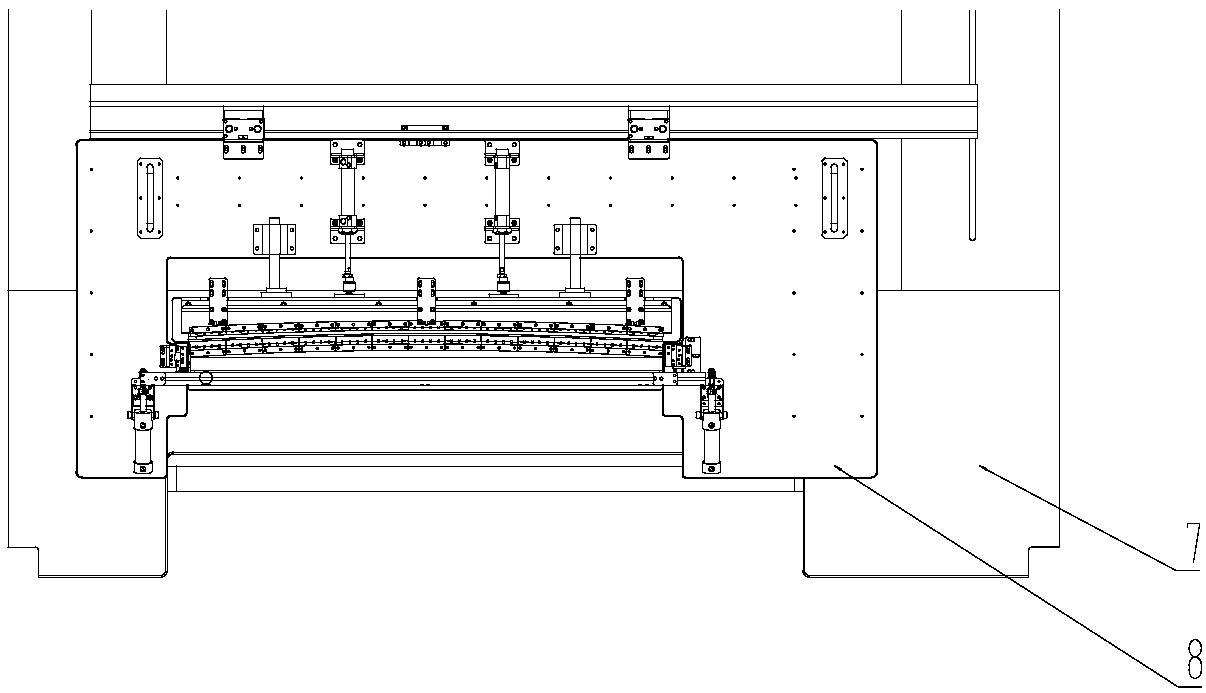

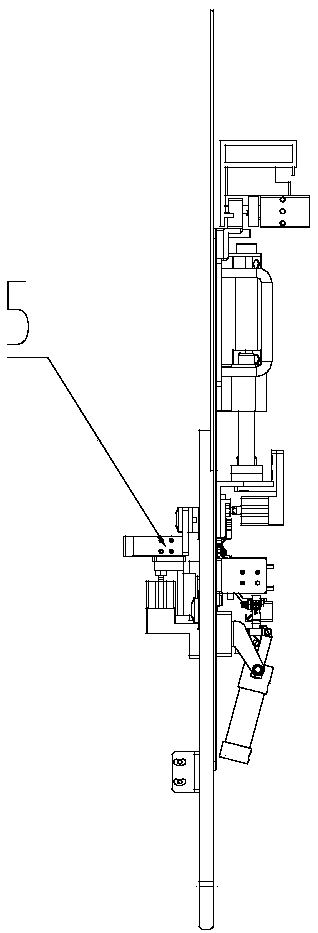

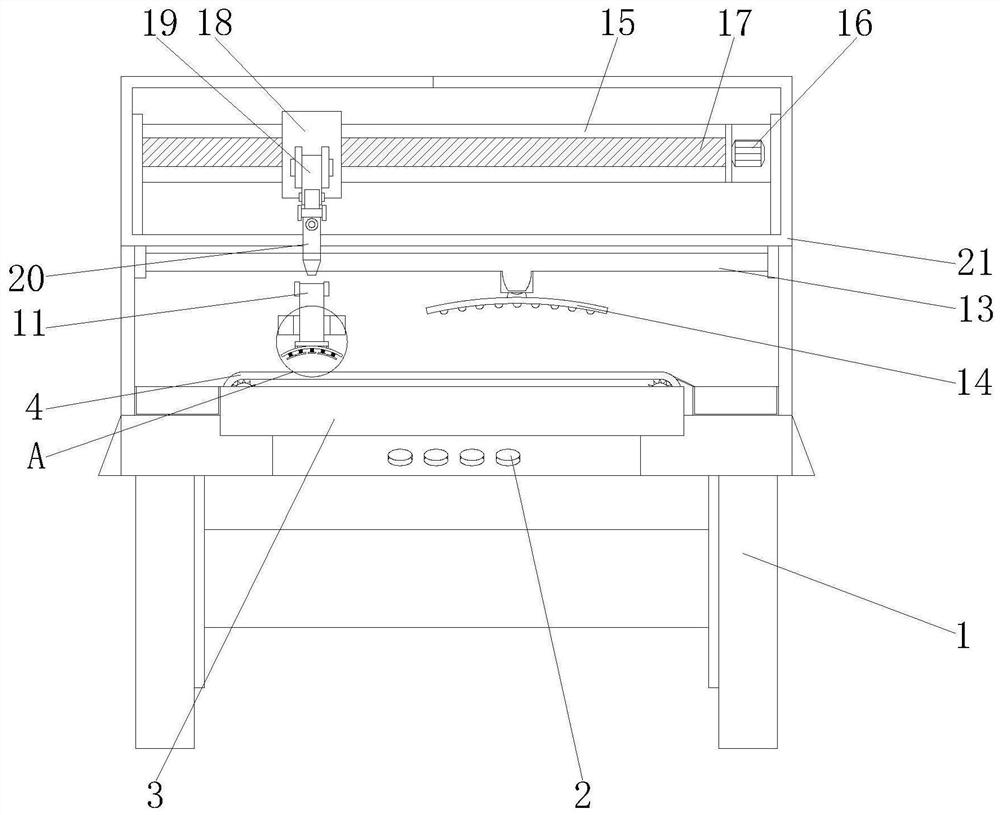

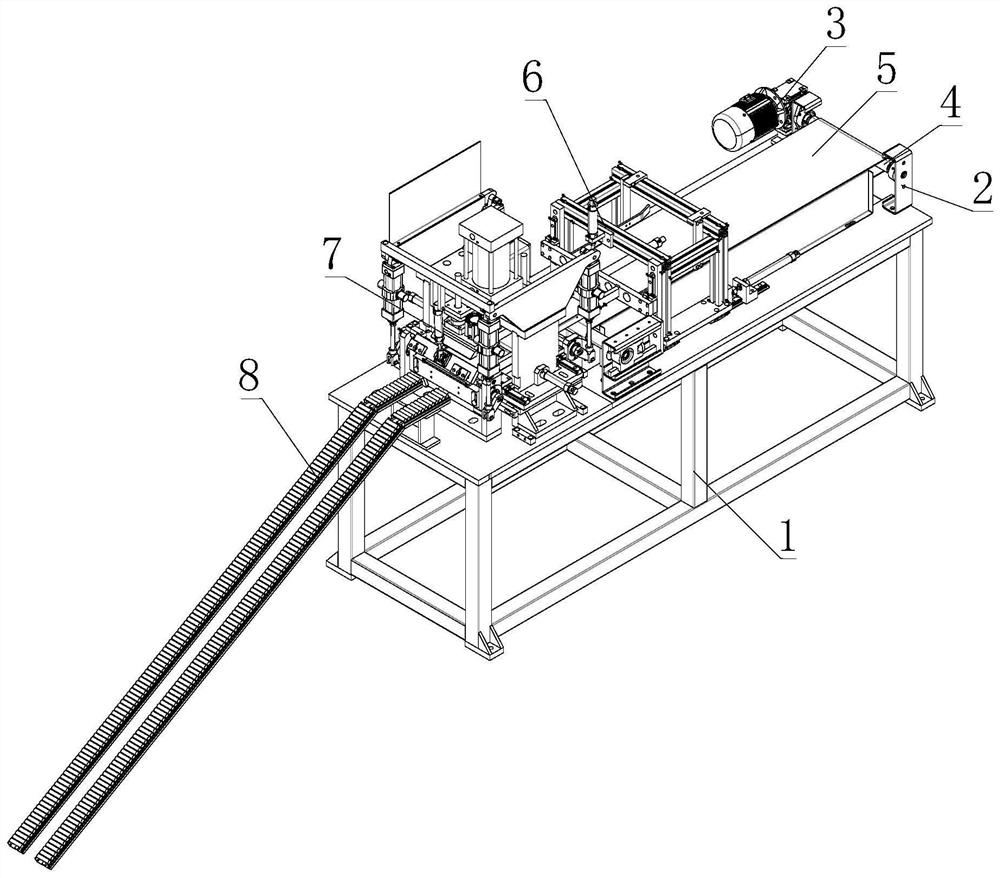

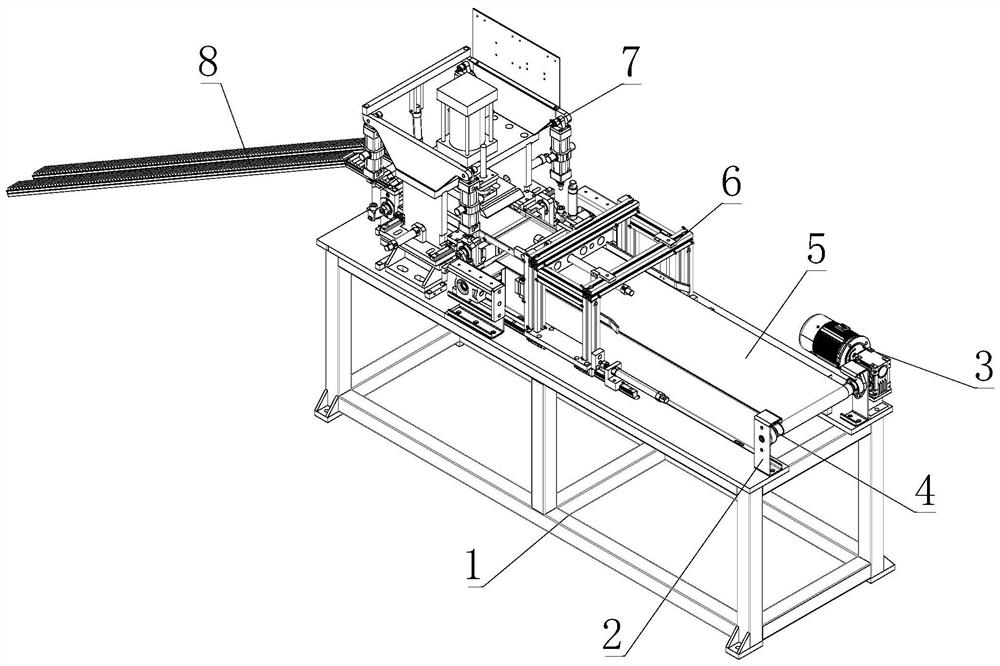

Roof bolt driller operation system

PendingCN108222986AReduce manual processesHigh degree of automationDerricks/mastsAnchoring boltsEngineeringRock bolt

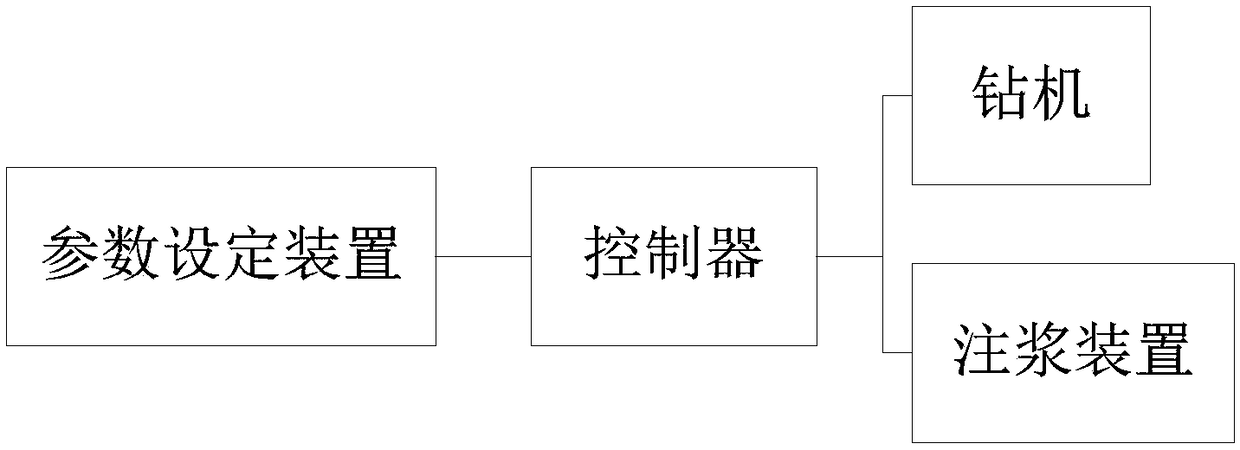

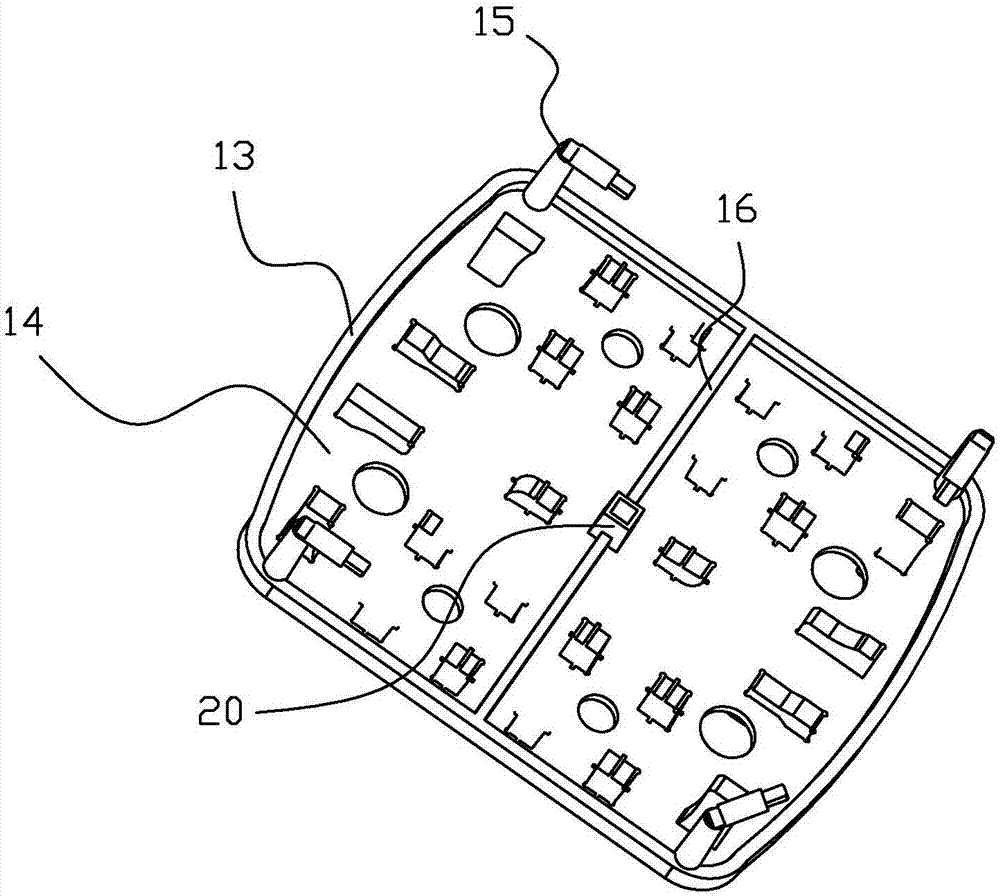

The invention relates to a roof bolt driller operation system which comprises a driller, a grouting device, a controller and a parameter setting device. The driller is used for drilling a rock mass and placing a roof bolt; the grouting device is used for grouting a roof bolt hole; the controller is electrically connected with the driller and a power portion of the grouting device; the parameter setting device is electrically connected with the controller and used for setting the action of the power portion of the grouting device. Drilling, roof bolt mounting and grouting processes of the roofbolt driller are controlled by the controller, the action of all portions is set by the parameter setting device, and the controller drives all the power portions to work. A roof bolt mounting deviceis integrated on the driller, a roof bolt clamping component can clamp the roof bolt in a roof bolt storage portion and place the roof bolt at the front end of a power head, and the roof bolt is pushed into the roof bolt hole by the aid of thrust of the power head. By the aid of the processes, automation degree can be improved, and the problems of long the construction period of the roof bolt driller in the operation process and low construction efficiency can be solved.

Owner:BEIJING XINNENGZHENGYUAN INTELLIGENT EQUIP CO LTD

Anchor rod mounting system

Owner:BEIJING XINNENGZHENGYUAN INTELLIGENT EQUIP CO LTD

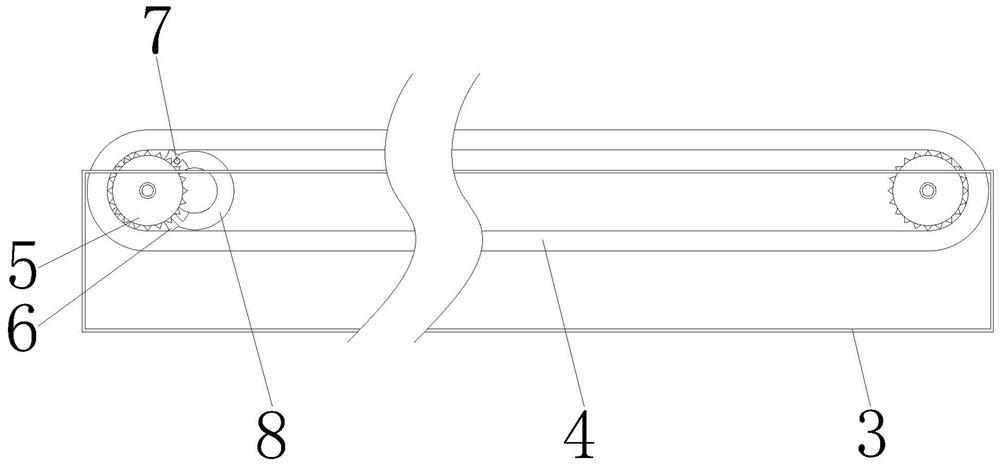

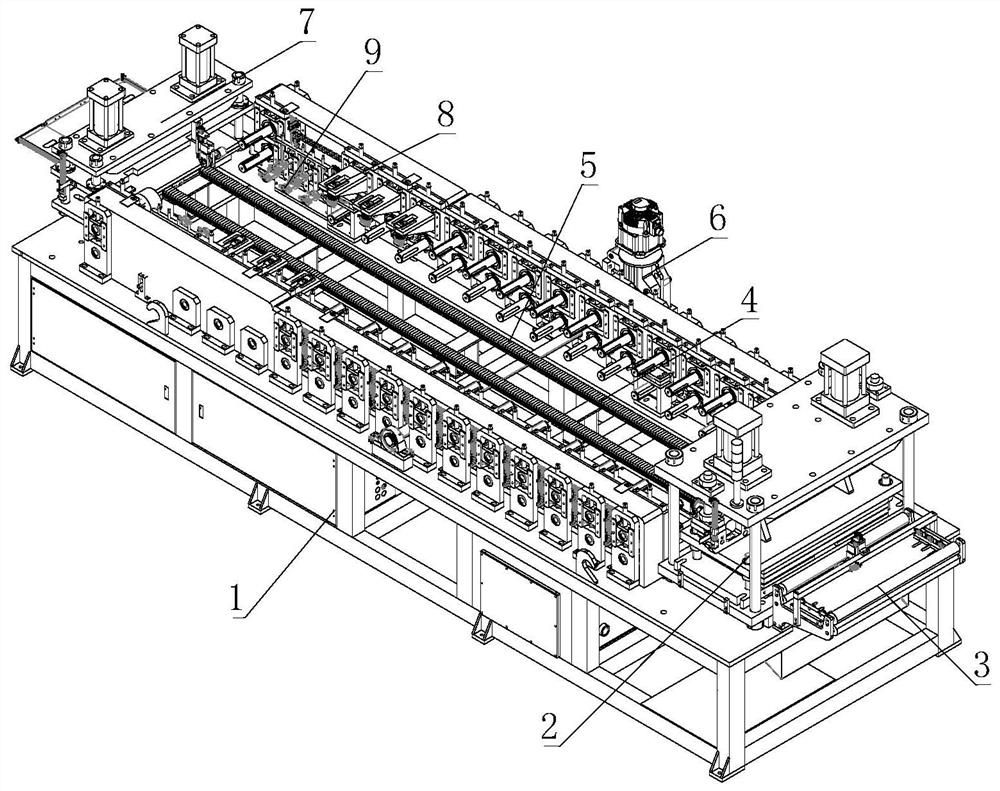

Intelligent conveying system for bobbin film sleeving and packaging production line

PendingCN112777026AIncrease installed capacityReduce work proceduresWrapping material feeding apparatusConveyor wrappingManufacturing engineeringBobbin

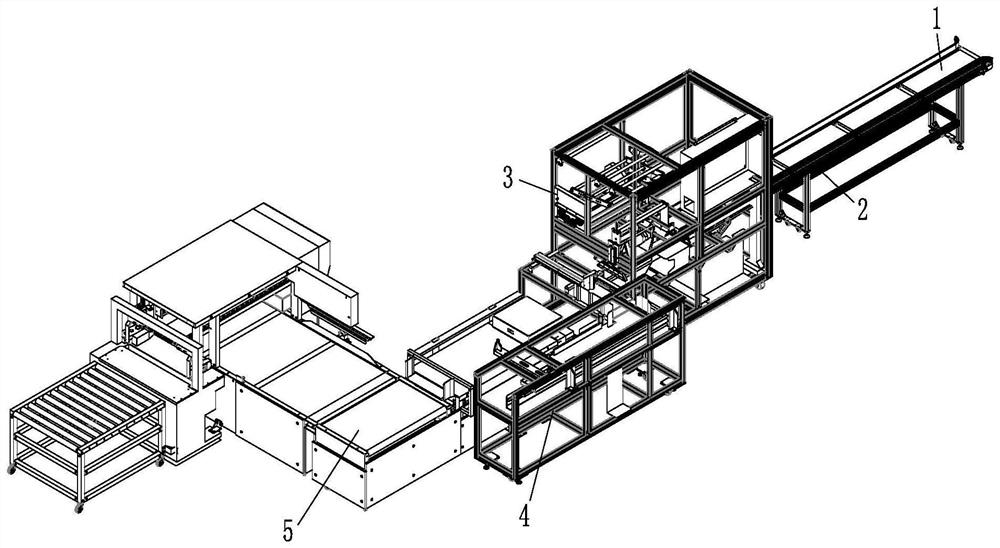

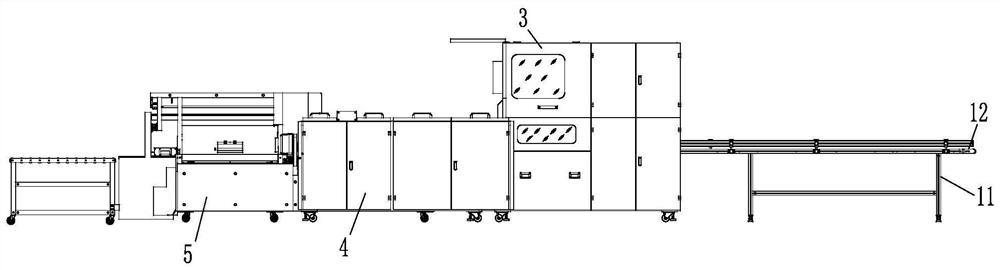

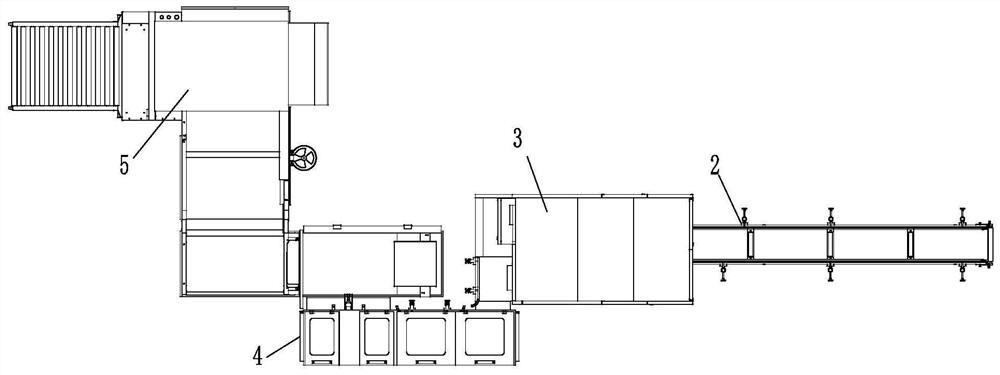

The invention relates to an intelligent conveying system for a bobbin film sleeving and packaging production line. The system comprises a conveying system, a large and small head detection system, a film sleeving system, an automatic arrangement system and a packaging system which are sequentially arranged. The film sleeving system comprises a film storage assembly, a film feeding assembly, a bagging assembly and an overturning assembly, wherein the film feeding assembly is arranged below the film storage assembly, a bagging assembly is arranged on one side of the lower portion of the film feeding assembly and is in butt joint with the overturning assembly. The conveying system comprises a rack and a conveying belt arranged on the rack. The conveying belt comprises a plurality of small conveying belts with the same length. The large and small head detection system comprises a first limiting switch, a second limiting switch, a third limiting switch and a control system, wherein the second limiting switch and the third limiting switch are arranged on one side of the small conveying belt closest to the film sleeving system, and the small conveying belt closest to the film sleeving system is arranged below the film conveying assembly. The automatic film sleeving, packaging and conveying process of bobbins is achieved, and the production efficiency is improved.

Owner:无锡凡琉智能科技有限公司

Automatic overturning device for forward hook of skip car

PendingCN106743430AReduce manual processesReduce manual labor intensityConveyor partsAutomotive engineering

Owner:YONEGY LOGISTICS AUTOMATION TECH

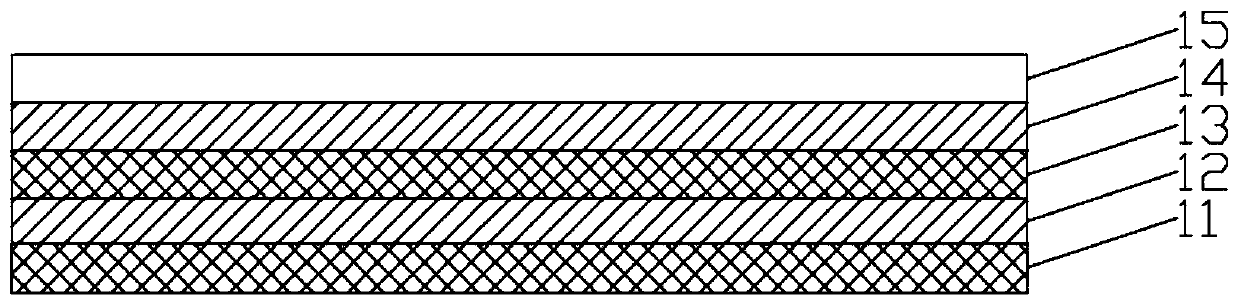

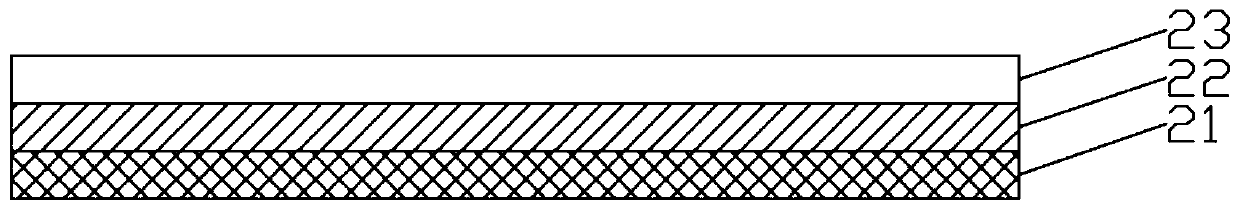

Ultrathin double-sided nano-silver capacitive screen and preparation method thereof

PendingCN111208921AEtching is achieved quicklyReduce manual processesInput/output processes for data processingPhysicsChemistry

The invention relates to the field of capacitive screens, in particular to an ultrathin double-sided nano-silver capacitive screen and a preparation method thereof.The ultrathin double-sided nano-silver capacitive screen comprises a double-sided nano-silver film, an OCA adhesive layer and a glass cover plate, and the double-sided nano-silver film and the OCA adhesive layer are both single layers.The preparation method of the ultrathin double-sided nano-silver capacitive screen comprises the steps that the OCA adhesive layer is attached to the double-sided nano-silver film in a roll-to-roll mode, and the double-sided nano-silver film is covered with the glass cover plate. According to the ultrathin double-sided nano-silver capacitive screen, the technological process is simplified, the production period is short, mechanical work is set, the low yield caused by manual misoperation is reduced, and the overall cost is reduced. Meanwhile, the thickness of the capacitive screen is reduced,and the touch experience effect is improved.

Owner:SHENZHEN HUAKE COMM TECH CO LTD

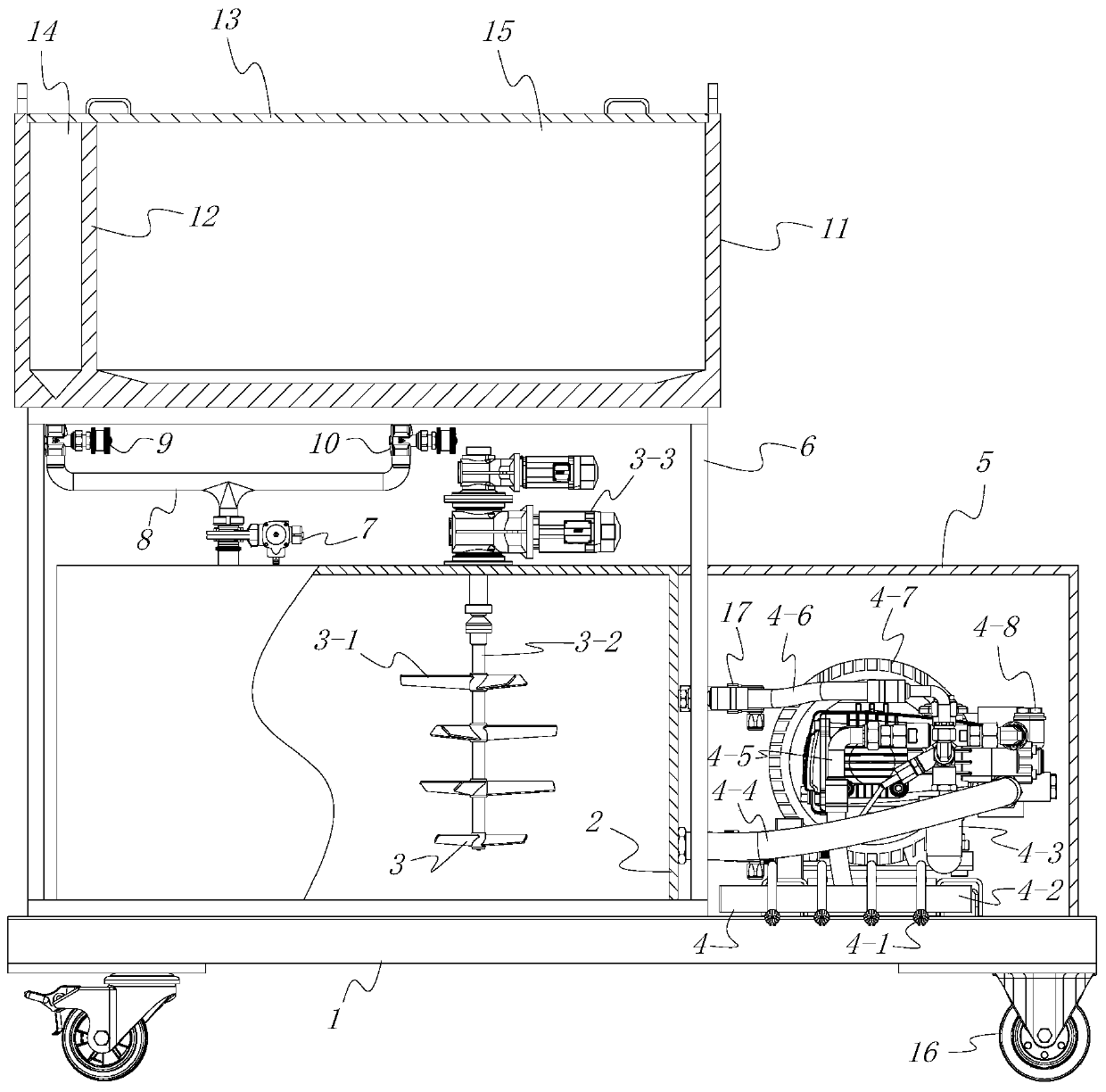

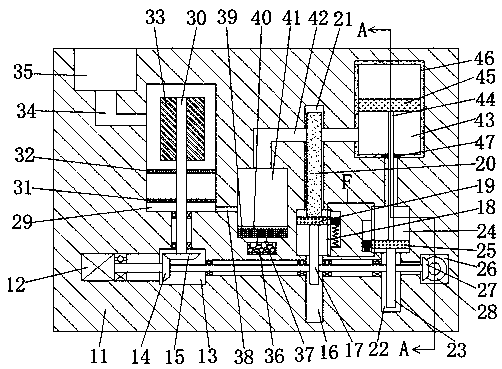

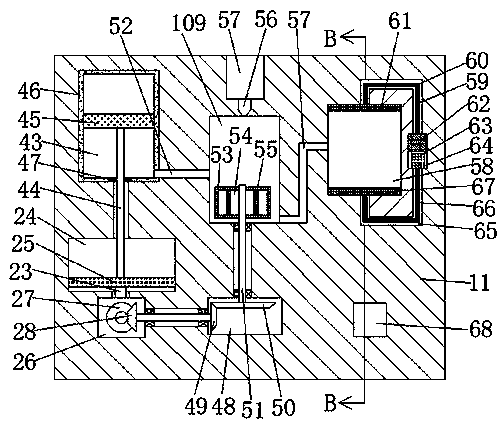

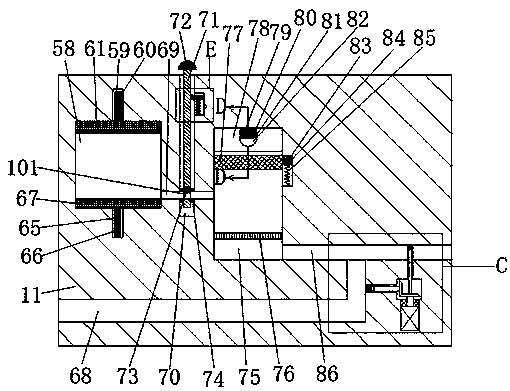

Atomizing disinfection device for medical blood collection platform

InactiveCN110152040AReduce manual processesHigh degree of automationRotary stirring mixersTransportation and packagingElectricityWater storage tank

The invention relates to an atomizing disinfection device for a medical blood collection platform. The device comprises a base, wherein the bottom of the base is connected with rollers, the top face of the base is connected with a mixing box and a water mist generation device connected with the mixing box, and the mixing box is connected with a stirring device; the top face of the base is connected with a water tank supporting frame, the top face of the water tank supporting frame is provided with a water storage tank, the water storage tank is internally and fixedly connected with a partitionplate dividing an inner cavity of the water storage tank into a first chamber and a second chamber, the bottom of the water storage tank is provided with a first throttle valve and a second throttlevalve which are communicated with the first chamber and the second chamber respectively, and a water outlet of the first throttle valve is communicated with a water outlet of the second throttle valvethrough a tee pipe; a water outlet of the tee pipe is connected with a solenoid valve, and a water outlet of the solenoid valve is communicated with an inner cavity of the mixing box through a pipeline; the mixing box is connected with a first liquid level meter and a second liquid level meter which are electrically connected with the solenoid valve, and the first liquid level meter is located above the second liquid level meter. The atomizing disinfection device for the medical blood collection platform has the advantages that the structural design is simple and reasonable, the degree of automation is high, and the disinfection efficiency is high.

Owner:TIANJIN HAIMAI MEDICAL TECH

Multi-level wastewater treatment device and application method thereof

InactiveCN109231718AQuick filterSimple structureWater treatment parameter controlSpecific water treatment objectivesWastewaterWater quality

The invention discloses a multi-level wastewater treatment device and an application method thereof. The multi-level wastewater treatment device comprises a main body, wherein a transmission device isarranged in the main body; the transmission device is connected with a physical device, a chemical device and a biological device; the transmission device comprises a physical device gear cavity formed in the main body; a front driving bevel gear is rotatably arranged in the physical device gear cavity; a motor is fixed on the left side inner wall of the physical device gear cavity; the right endof the motor is connected with the front driving bevel gear in power fit through a rotary shaft. The multi-level wastewater treatment device disclosed by the invention has the advantages of easinessin operation, convenience in use, few manual processes and high automation degree; moreover, the device can be changed or repaired by detecting the wastewater quality, and cyclic treatment of the wastewater also can be realized.

Owner:ROLAND CORP

Product equipment for producing chicken bouillon

PendingCN111528434AImprove production rateImprove production efficiencyHollow article cleaningFood shapingOil and greaseHydraulic cylinder

The invention discloses product equipment for producing chicken bouillon. The product equipment comprises a high-pressure cooking pot, chutes are formed in two sides of the high-pressure cooking pot,and two chutes are slidably connected with sliding blocks arranged in the middles of two sides of workbenches correspondingly, two mounting grooves are formed in the top end of each two workbench, electric hydraulic cylinders are mounted in the four mounting grooves correspondingly, and four electric hydraulic cylinders are corresponding two-to-two; telescopic ends of four electric hydraulic cylinders are fixedly connected with two sides of bottom ends of two lifting plates. The production equipment for producing chicken bouillon, a cross-shaped rotary table is arranged, when grease and impurities on the surface of a high-temperature cooking pot need to be scraped out, an oil scaping end of the cross-shaped rotary table extends into the high-temperature cooking pot; when the high-temperature chicken needs to be ground, a grinding end of the cross-shaped rotary table extends into the high-temperature cooking pot and grinds the chicken through a mechanism at the top of a pot cover, so that the preparation efficiency is improved, the manual procedures are reduced, and the working efficiency is improved.

Owner:杭州凤健宝生物科技有限公司

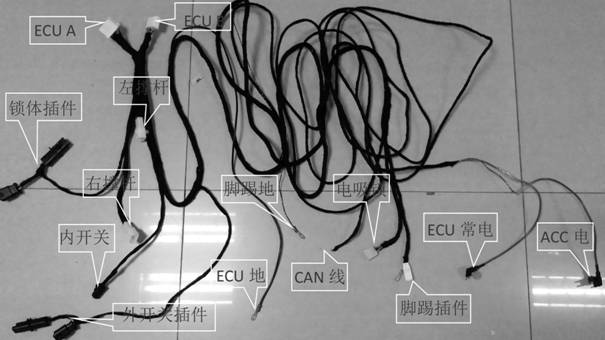

Electric tailgate driving system and control method

PendingCN111706209AImprove stabilityEasy to assemblePower-operated mechanismDoorsElectric machineryElectric control

The invention provides an electric tailgate driving system and a control method. An ECU (Electronic Control Unit) module is arranged in an electric control balance bar; a harness connector is also provided; the harness connector is electrically connected with the ECU module through a harness, and is used for connecting a vehicle control unit to receive instructions and power input of the vehicle control unit; the electronic control balance bar is connected with a driving bar through a wire harness; the ECU module is used for driving the driving bar to act; and the electronic control balance bar moves along with the action of the driving bar. The vehicle control unit sends an opening or closing instruction to the ECU module; the opening or closing instruction comprises a starting, rotatingdirection, speed adjustment, starting angle or stroke instruction of the driving bar; the ECU converts the opening or closing instruction into a PWM control instruction of a Hall motor; the PWM control instruction comprises a starting, rotating direction control, speed adjustment, opening angle or stroke instruction of the Hall motor; and the ECU module is placed in the electric control balance bar, so that enough mounting space is obtained and the stability of ECU operation is greatly improved.

Owner:武汉辰沃科技有限公司

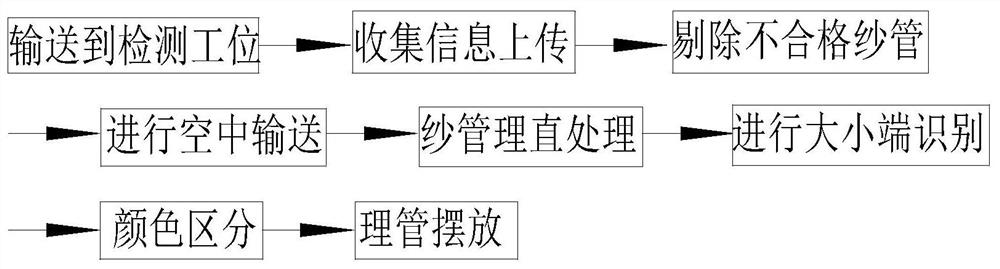

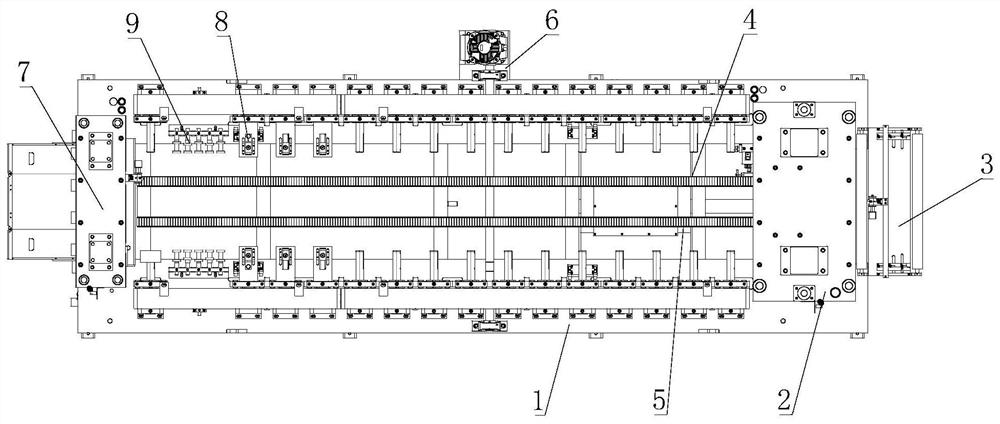

Method for arranging bobbins

ActiveCN112676177AAlleviate recruitment difficultiesAdvanced and reasonable management technologySortingBobbinTransmission belt

The invention relates to the technical field of textile machinery processes, in particular to a method for arranging bobbins. In an existing bobbin arranging method, the mode that a plurality of middle procedures adopt manual conveying exists, efficiency is low, and only a few colors can be recognized, arranged and placed through another existing method. The method for arranging the bobbins comprises the following steps that the bobbins are conveyed to a detection station in a bobbin lifting separator; information of each bobbin is collected and uploaded to a control device; unqualified bobbins are separated, and qualified bobbins are conveyed upwards; the qualified bobbins are conveyed to a transmission belt of an aerial conveying mechanism; the qualified bobbins are conveyed to two lifts in front of a bobbin arranging center and subjected to straightening treatment, and the bobbins are straightened to be arranged in one direction through a large-end and small-end recognition device; color information is collected and uploaded to the control device; and after color distinguishing of the control device, the bobbins are driven into the corresponding channels, enter turnover frames with the corresponding colors and are placed in a color separation mode. Conveyor belt conveying is adopted in the whole process, manual procedures are not needed, accurate recognition is achieved, and color recognition is not limited by the number.

Owner:浙江宝耀智能科技有限公司

Glass lens hot-pressing device

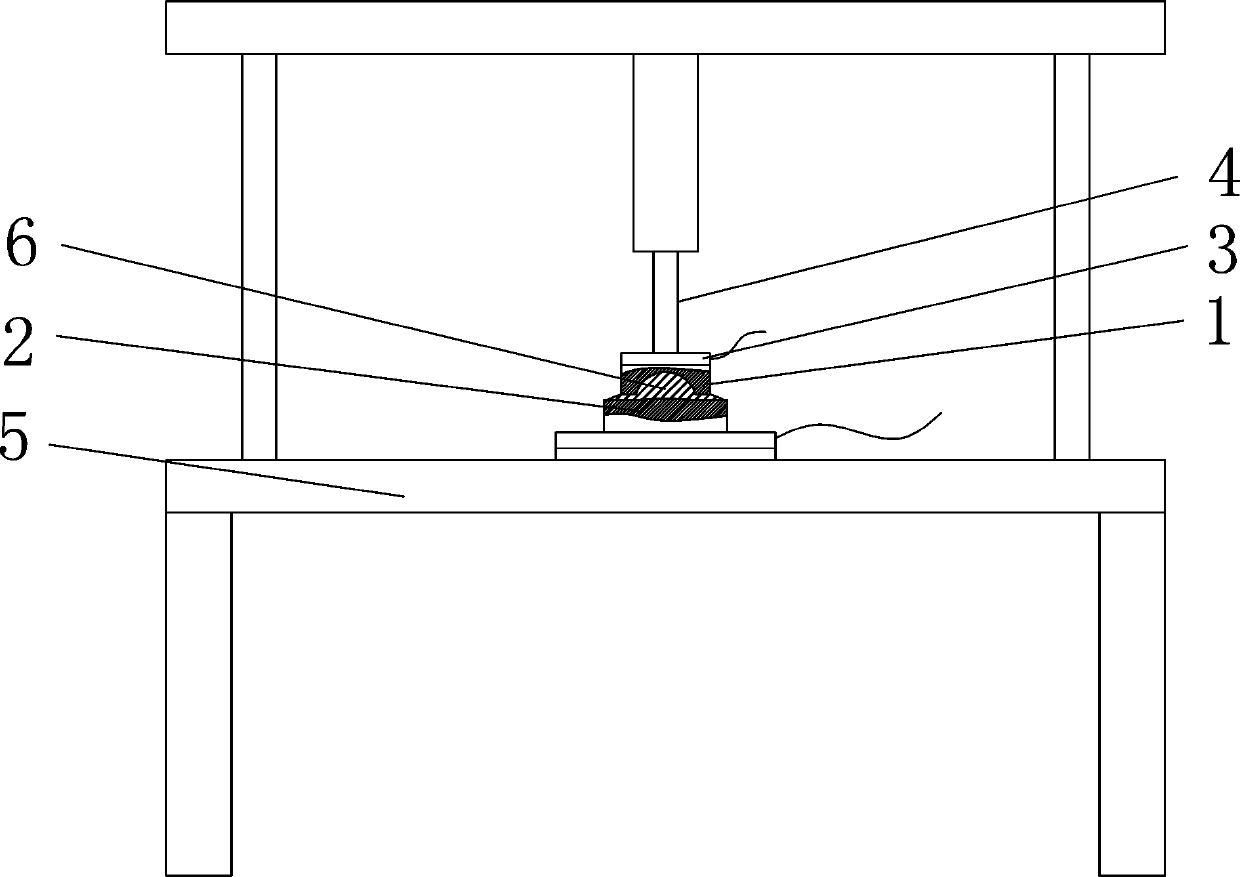

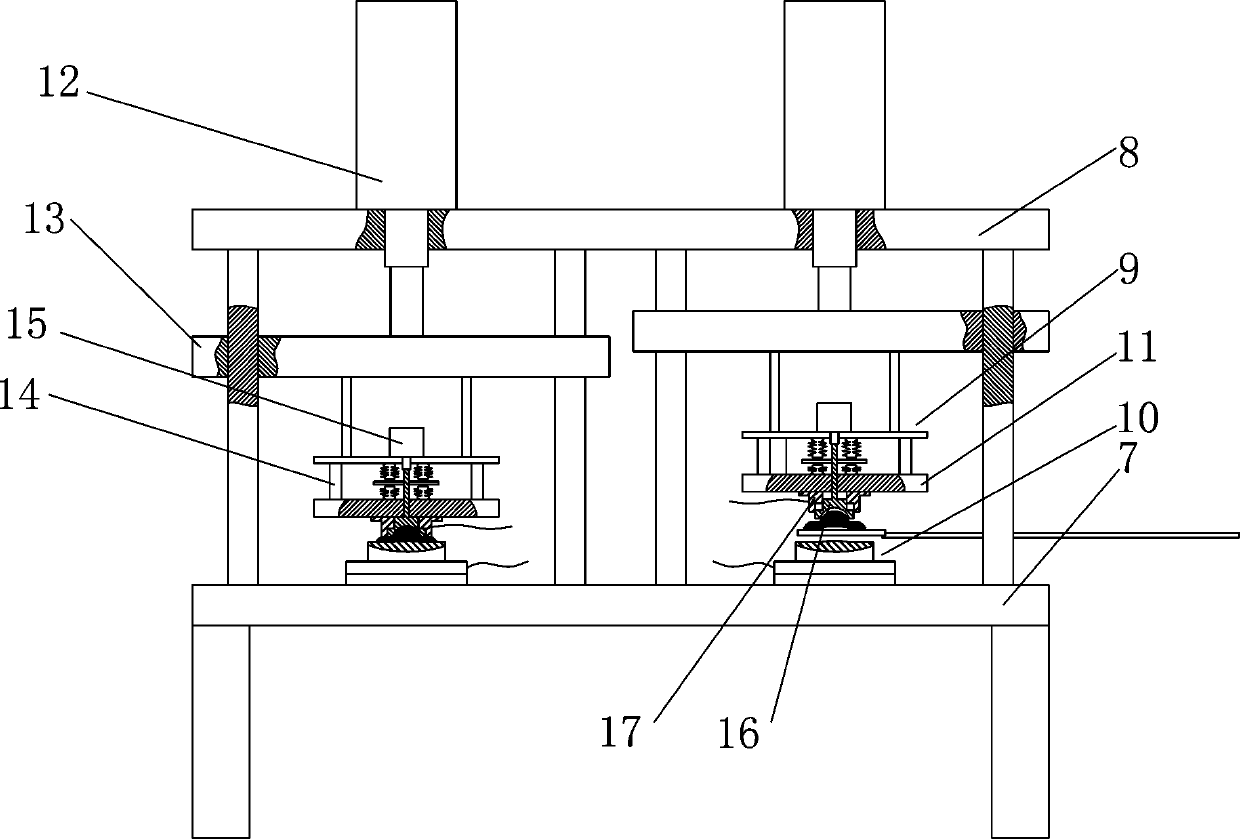

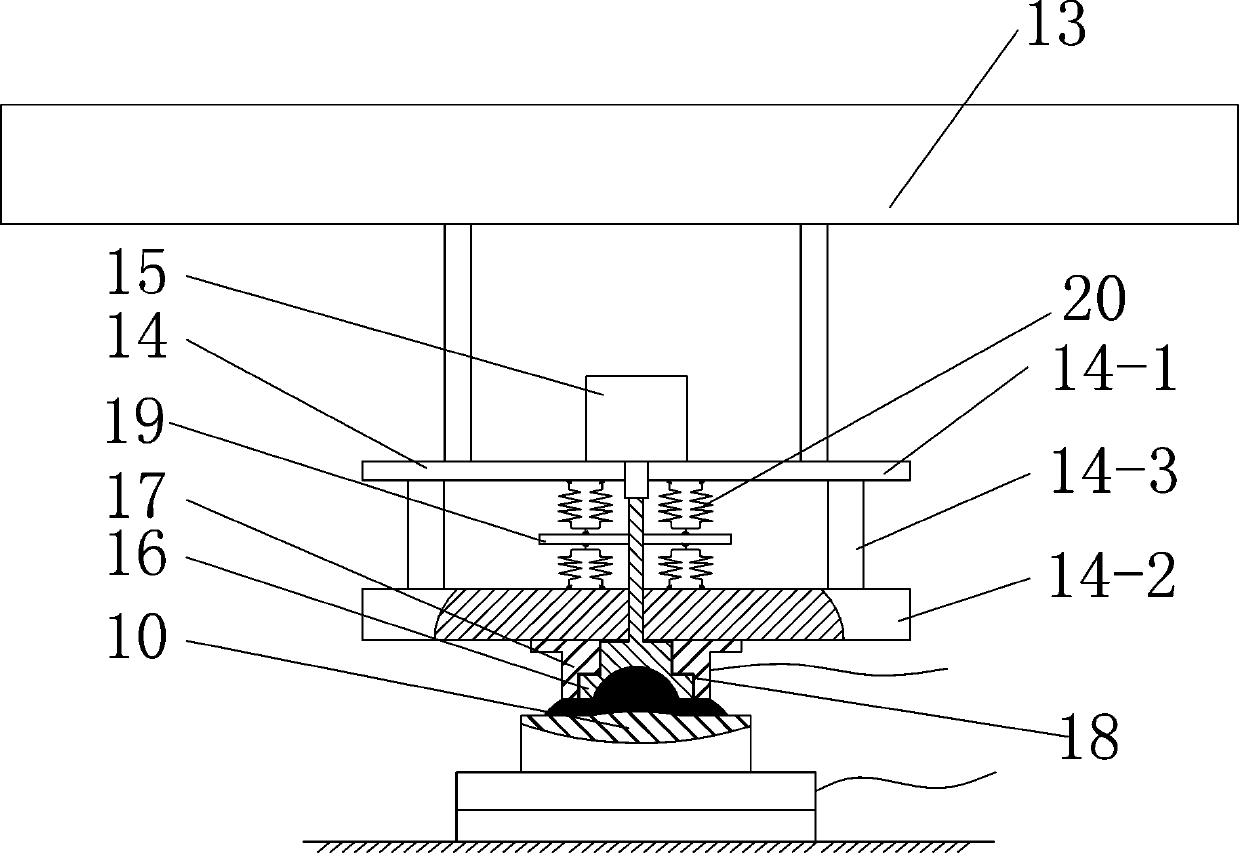

InactiveCN111186986AGuaranteed installationGuaranteed normal expansionGlass pressing apparatusEngineeringWorkbench

The invention relates to a glass lens hot-pressing device, which comprises a hot-pressing workbench, wherein a machine seat is arranged on the hot-pressing workbench, two sets of independent hot-pressing mechanisms are arranged between the hot-pressing workbench and the machine seat, each set of the hot-pressing mechanism comprises a hot-pressing lower die installed on the hot-pressing workbench and a hot-pressing upper die installed on the machine seat, the hot-pressing upper die comprises a first air cylinder, the lower end of the first air cylinder is connected with a sliding plate, the lower end of the sliding plate is connected with an installation frame, a second air cylinder is arranged on the installation frame, the lower end of the second air cylinder is connected with an upper die, and the upper die is sleeved with a heating disc. The glass lens hot-pressing device provided by the invention can improve the working efficiency.

Owner:HUBEI PAIRUISI OPTICAL GLASS TECH CO LTD

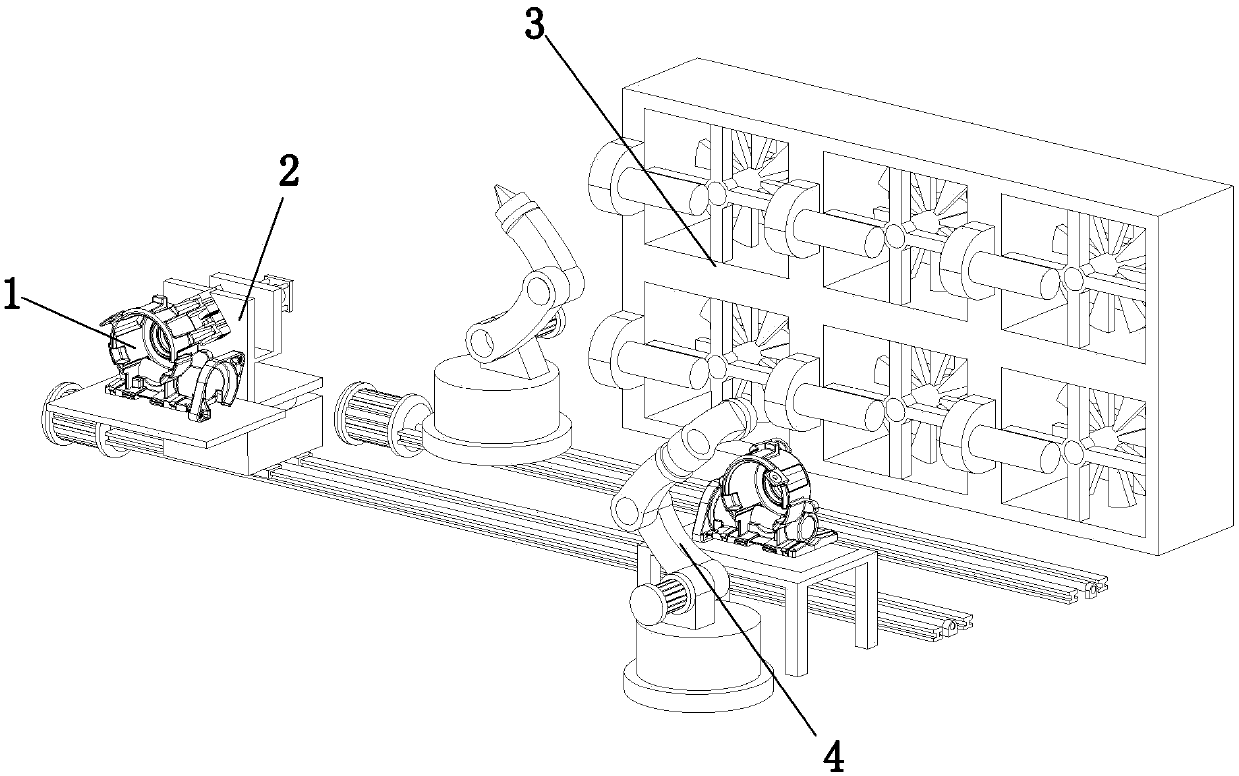

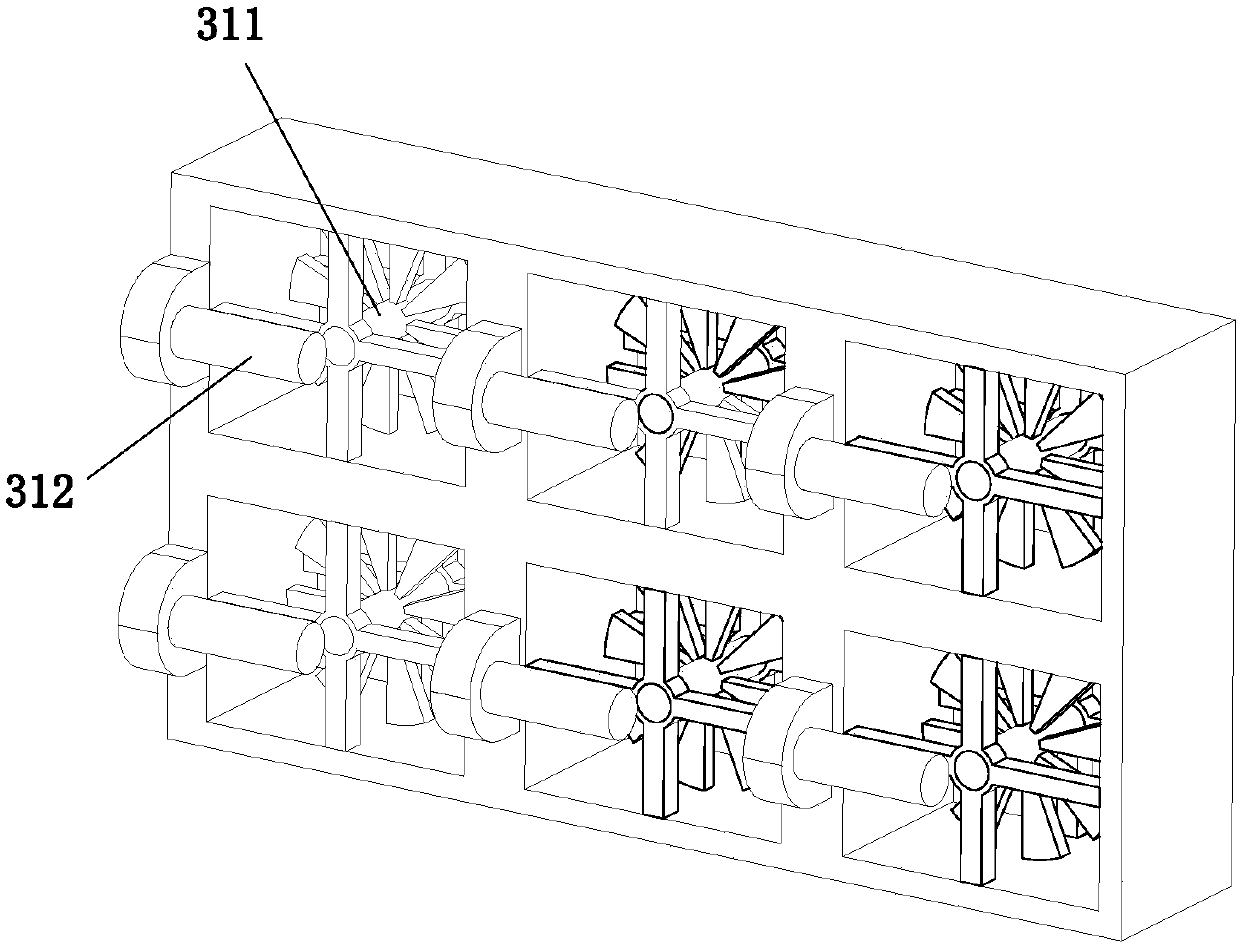

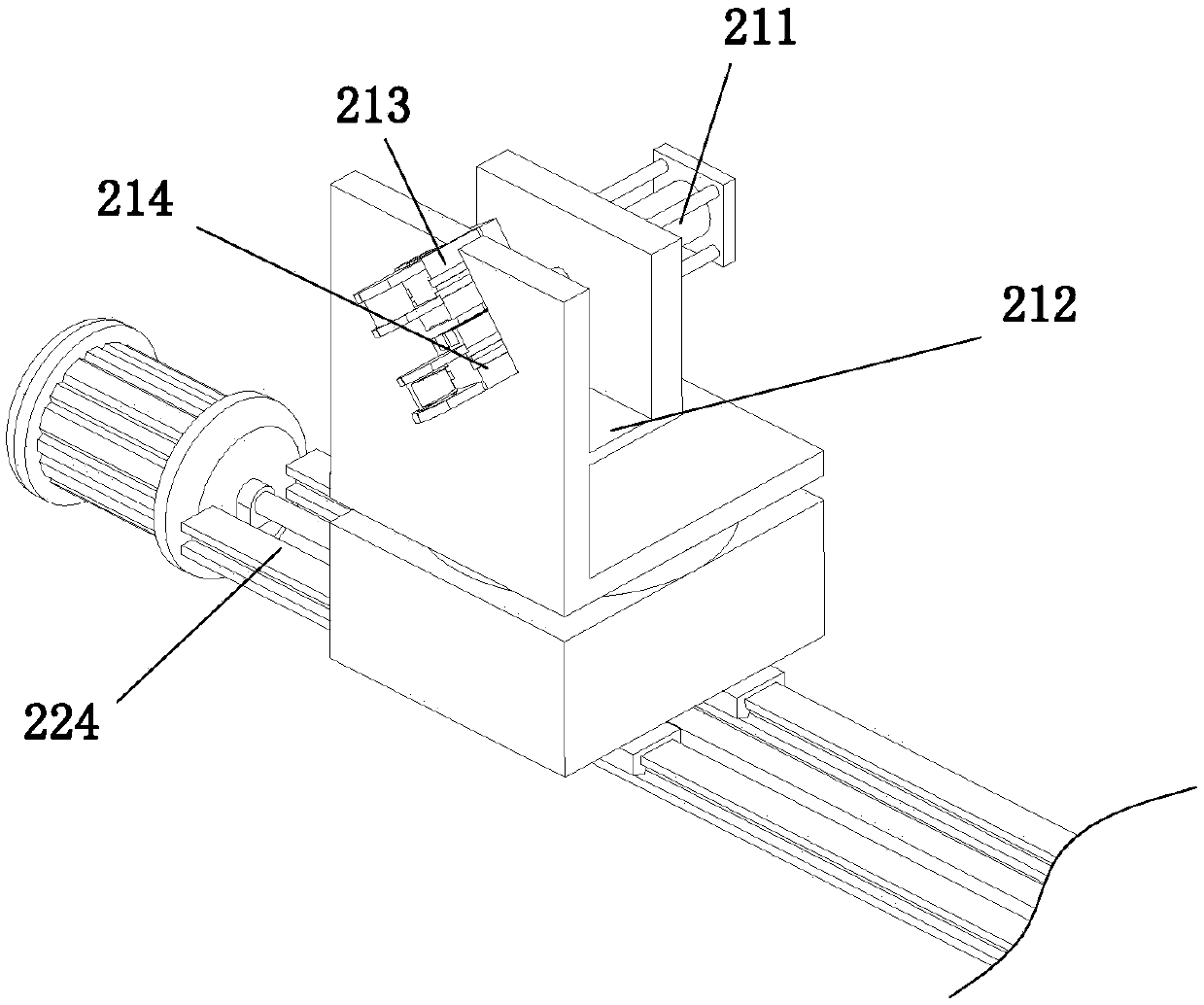

Reduction box shell of aluminum die-casting, forming and steering system and production assembly line of reduction box shell

PendingCN108679201AExtended cooldownAvoid deformationGearboxesGear lubrication/coolingMaterial removalGear wheel

The invention relates to the field of die-casting equipment, in particular to a reduction box shell of an aluminum die-casting, forming and steering system and a production assembly line of the reduction box shell. The reduction box shell comprises an accommodating slot used for accommodating a planetary gear and a through hole used for accommodating a rotary shaft, wherein the axis of the accommodating slot is perpendicular to that of the through hole; the production assembly device comprises a material take device, an air-cooling device, a material removal device and a control device; the material take device comprises a material take assembly and a rotary platform; the air-cooling device comprises an air-cooling assembly and a conveying assembly; the material removal device comprises apositioning table and a material removal assembly; and the control device comprises a controller and a sensor assembly. The reduction box shell enables a product to be not deformed due to the fact theproduct easily has a too high temperature in a stamping process, and reduces labor cost; and the periphery of a descending robot is equipped with a protective net, and operation according to set program is implemented, so that a working safety coefficient of an operator is greatly increased.

Owner:宁波爱柯迪精密部件有限公司

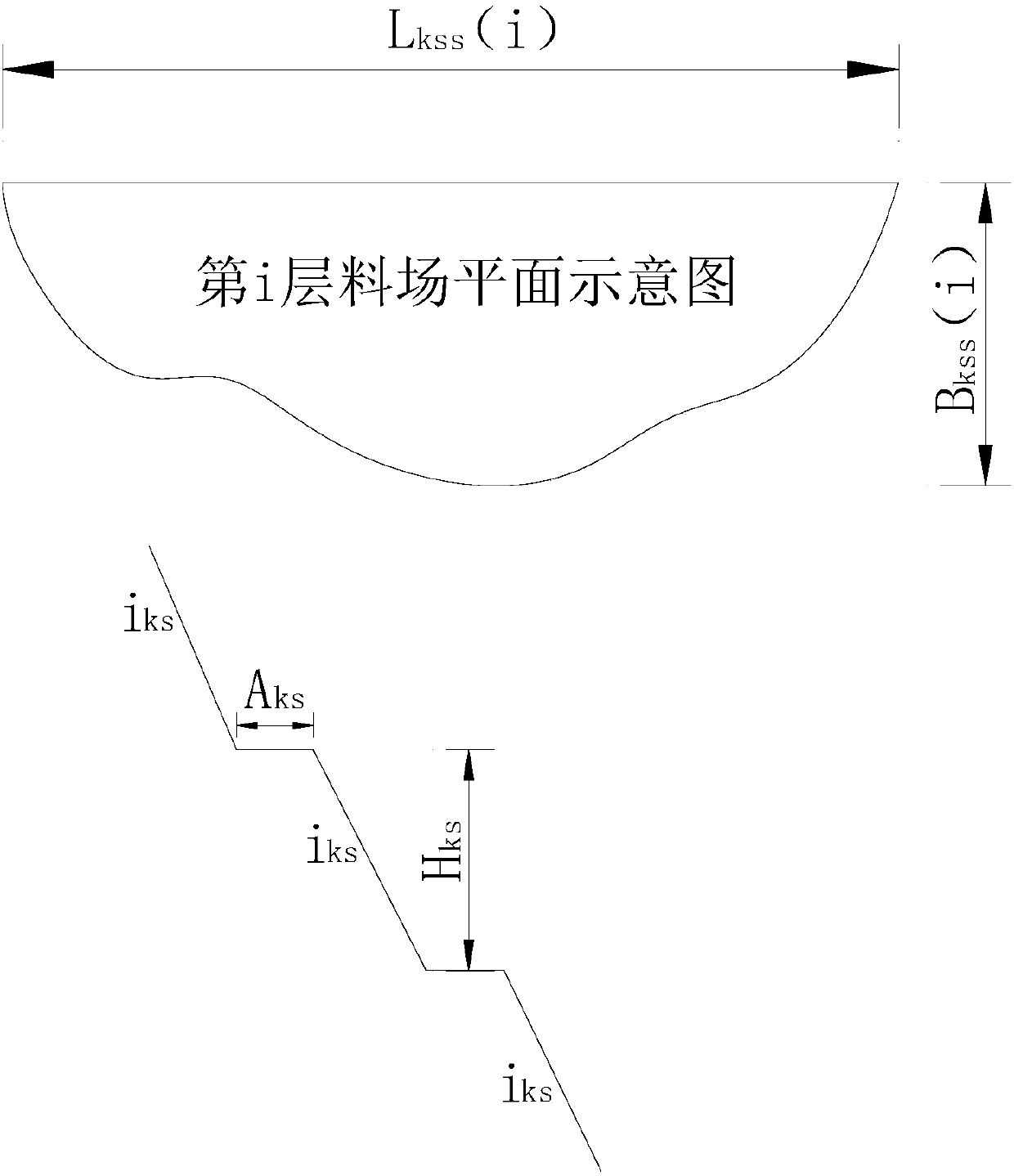

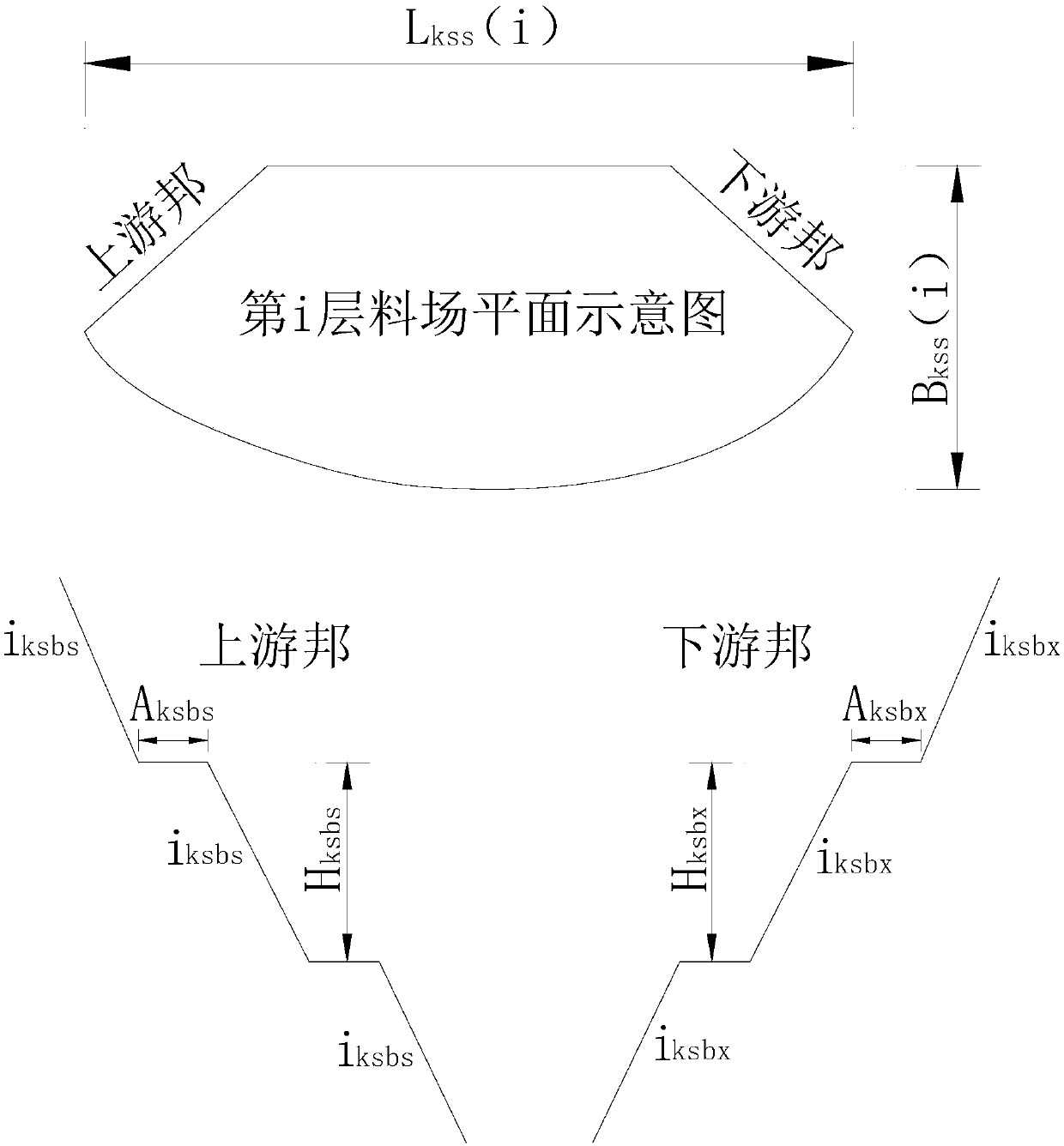

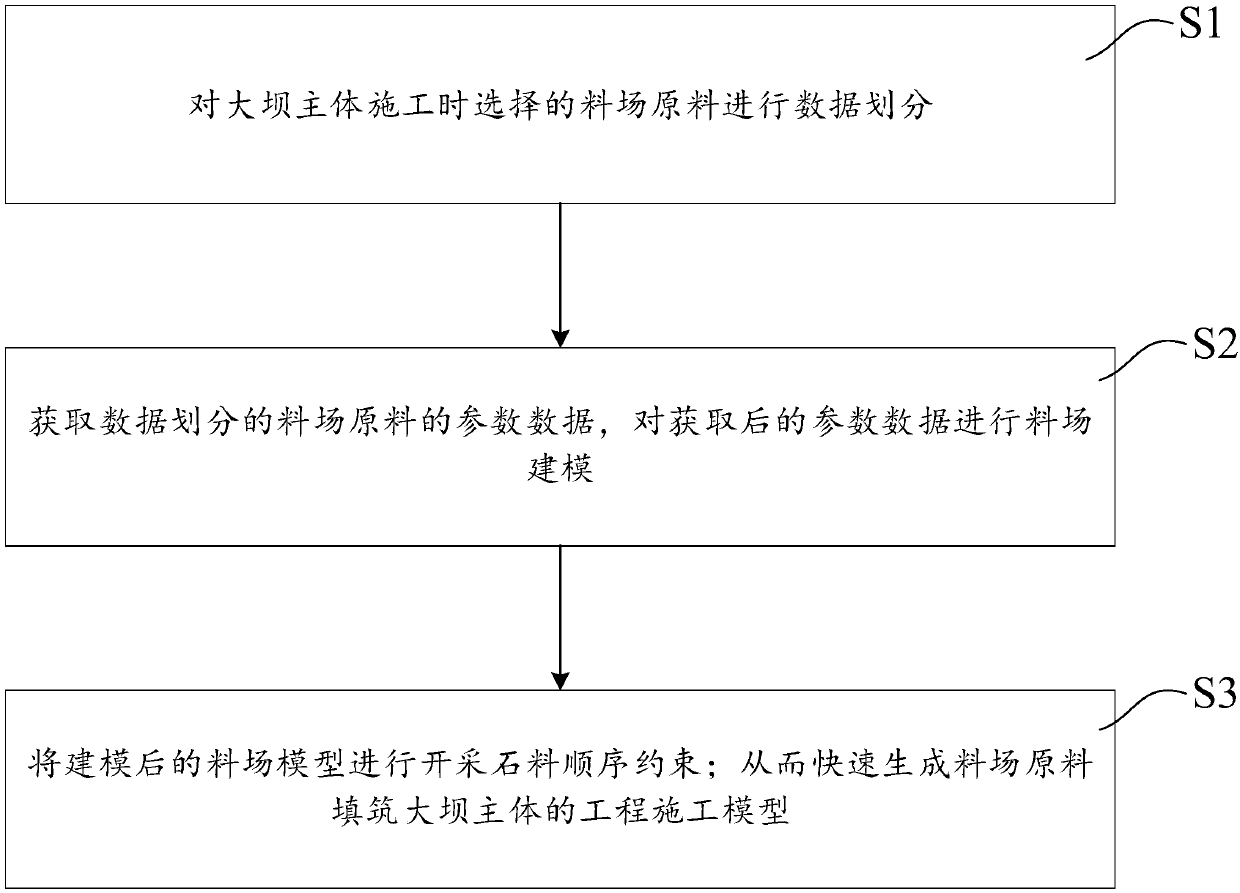

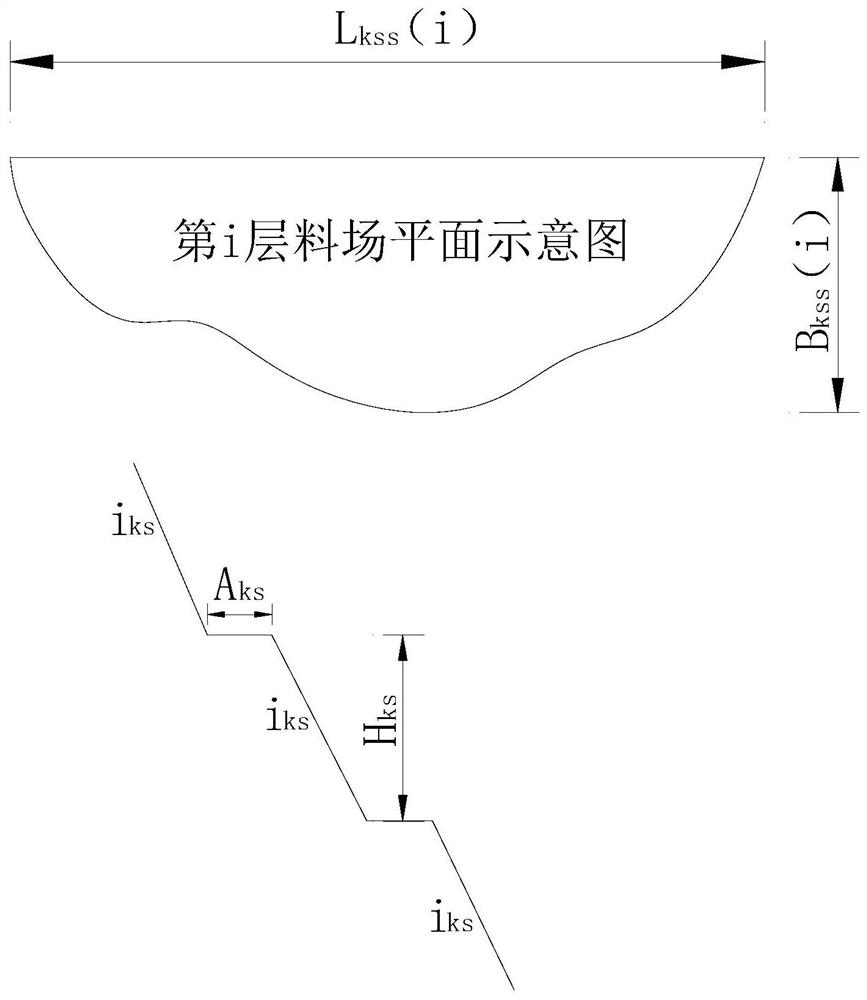

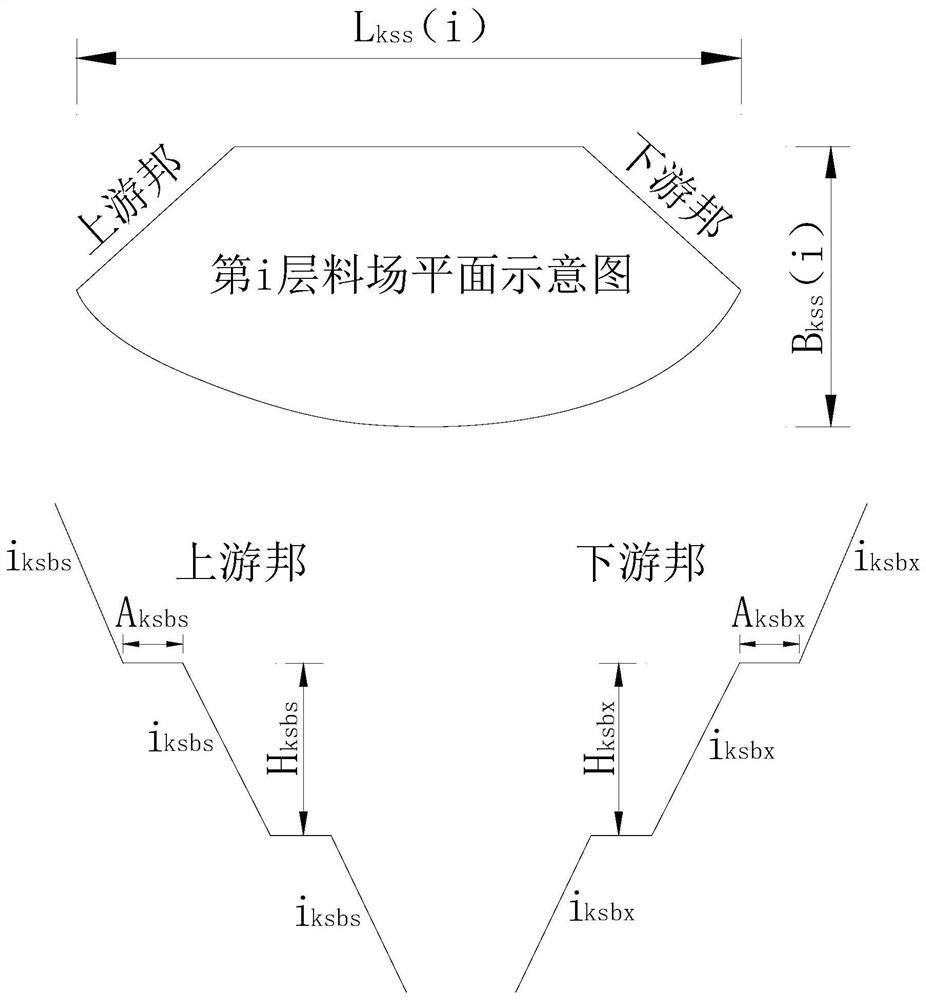

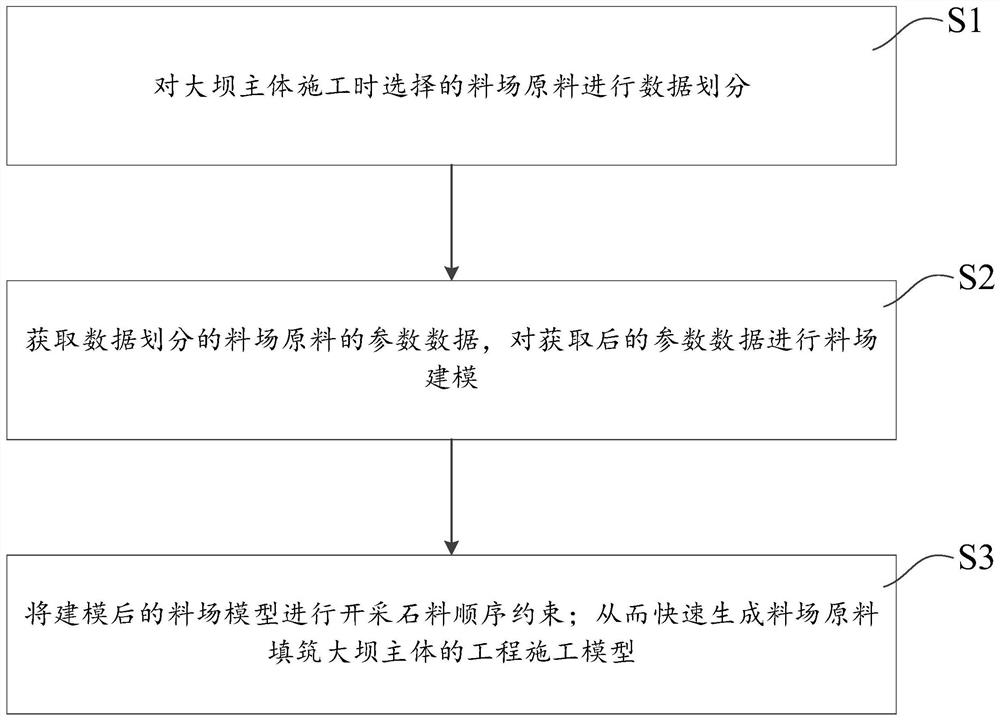

Dam engineering material field digital modeling optimization method

ActiveCN107908852AReasonable useAccurate data collectionForecastingDesign optimisation/simulationSoil coreDigitization

The invention provides a dam engineering material field digital modeling optimization method which comprises the following steps: S1, data partitioning is carried out on the material field raw materials selected during construction of a dam body; S2, acquiring parameter data of the data-partitioned material field raw materials, and carrying out material field modeling on the obtained parameter data; S3, performing mining stone sequence constraint on the modeled material field model, so that an engineering construction model of the material field raw materials filling the dam body is quickly generated. According to the embodiment, the big data of the construction resources configured for the material field is calculated to obtain the engineering construction progress, the acquired collection data of the gravel soil core wall filling material field is standard and accurate, the manual working procedures are reduced, and the construction conditions are visual and concise.

Owner:CHENGDU XIMENG TEKE TECH DEV CO LTD

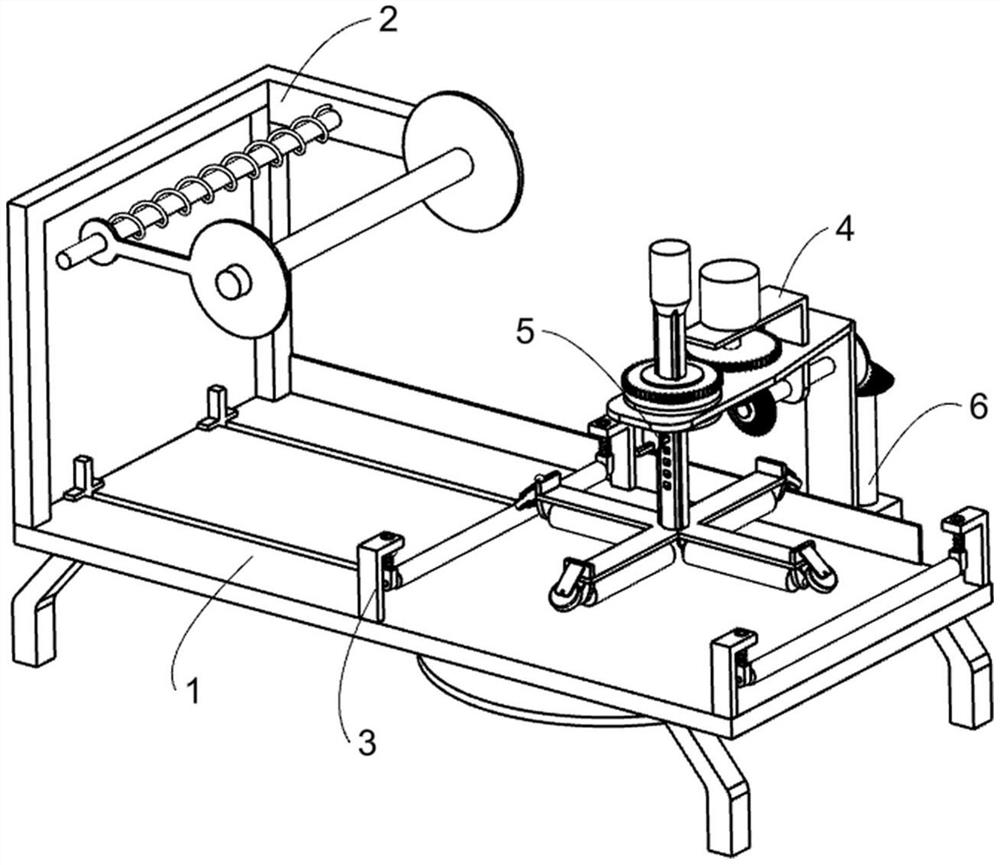

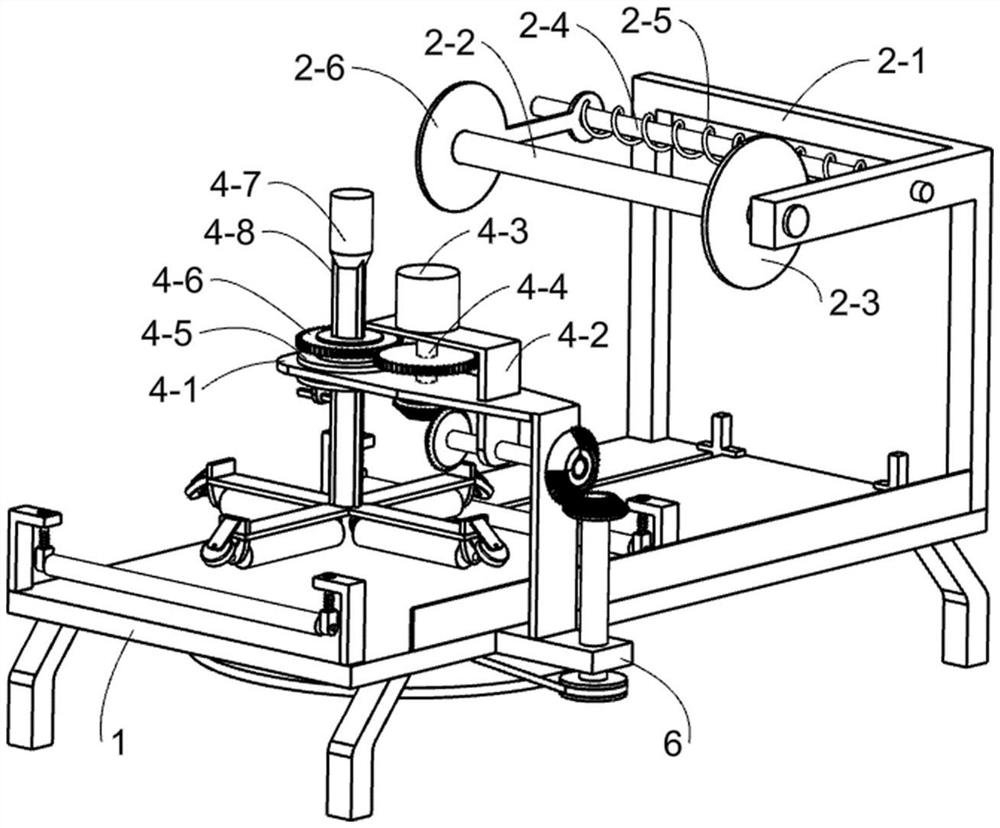

Film covering and flattening device suitable for aluminum plates with different thicknesses

The invention relates to an aluminum plate processing device, in particular to a film covering and flattening device suitable for aluminum plates with different thicknesses, and aims to solve the problems that bubbles generated after an aluminum plate is covered with a film cannot be completely eliminated by an existing aluminum plate flattening device, the phenomenon that the film is easy to fall off is easily caused, and the aluminum plate film covering and flattening processes cannot be combined together. The film covering and flattening device suitable for aluminum plates with different thicknesses comprises a base, an unreeling mechanism, a primary flattening mechanism and a rotary flattening mechanism and the like, wherein the unreeling mechanism is arranged on the upper side surface of one end of the base; the primary flattening mechanism is arranged on one side surface of the base; and the rotary flattening mechanism is arranged on the base. Two movable rollers can laminate the laminating film on the aluminum plate, and can transversely flatten the laminated film; a rotary frame drives four pressure rollers to rotate, so that the four pressure rollers can perform all-around flattening operation on the laminating film, and thus, the bubbles generated after film laminating are completely removed.

Owner:吴甲平

Car sunshade screen front arc sewing tooling

The invention discloses a car sunshade screen front arc sewing tooling comprising: fabric flanging, fabric pressing, product blanking, fabric pressing, fabric bending, tooling quick replacement, platen and tooling bottom plate; the sewing tooling is characterized in that: the tooling bottom plate is a carrier for the function of fabric pressing, product blanking, cloth pressing and fabric bending;the design changes the product from manual unloading to pneumatic automatic unloading, reduces the manual operation flow, and reduces the scrap rate obviously because of the direct arc of the productwhen it is bent.

Owner:上工富怡智能制造(天津)有限公司

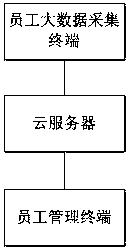

An employee big data management system

InactiveCN109087075AImprove management efficiencyReduce manual processesOffice automationData acquisitionManagement efficiency

The invention discloses an employee big data management system. The system comprises: an employee big data collection terminal, a cloud server and an employee management terminal. The employee big data collection terminal is used for collecting the check-in information, the personal matter application information and the personal matter inquiry information inputted by the employee. The cloud server is used for receiving and storing check-in information, personal matter application information and personal matter inquiry information. The employee management terminal is used for generating attendance table information, processing personal matter application information, and sending the processing result and attendance table information to the cloud server for storage. As compared with the prior art, the present invention has the following advantage: collecting employee check-in information and personal matter application information and storing them in cloud server, managing employee bigdata through employee management terminal, forming attendance table information and personal matter application processing result, feedback processing result when employee requests, reducing manual processing flow, thus improving enterprise and employee management efficiency.

Owner:安徽大尺度网络传媒有限公司

Digital modeling and optimization method for dam engineering material yard

ActiveCN107908852BReasonable useAccurate data collectionForecastingDesign optimisation/simulationArchitectural engineeringSoil core

The invention provides a dam engineering material field digital modeling optimization method which comprises the following steps: S1, data partitioning is carried out on the material field raw materials selected during construction of a dam body; S2, acquiring parameter data of the data-partitioned material field raw materials, and carrying out material field modeling on the obtained parameter data; S3, performing mining stone sequence constraint on the modeled material field model, so that an engineering construction model of the material field raw materials filling the dam body is quickly generated. According to the embodiment, the big data of the construction resources configured for the material field is calculated to obtain the engineering construction progress, the acquired collection data of the gravel soil core wall filling material field is standard and accurate, the manual working procedures are reduced, and the construction conditions are visual and concise.

Owner:CHENGDU XIMENG TEKE TECH DEV CO LTD

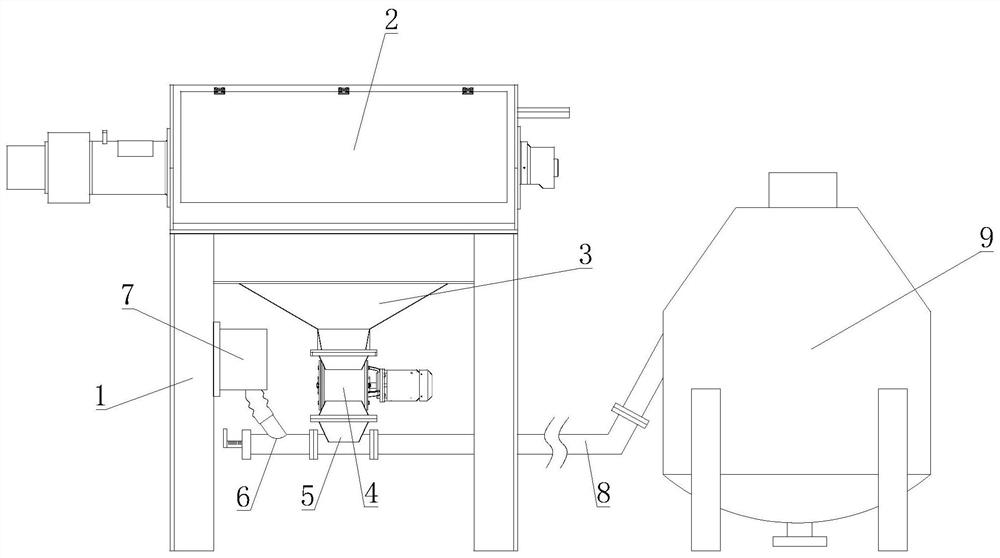

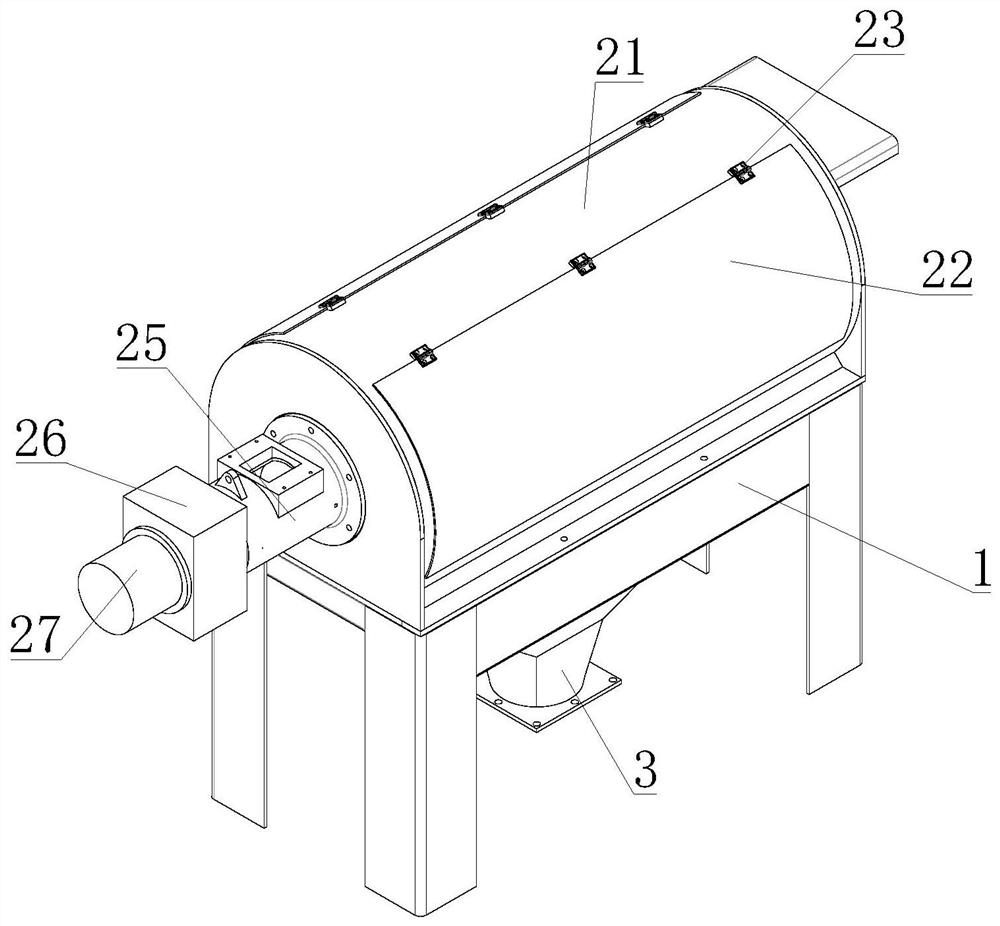

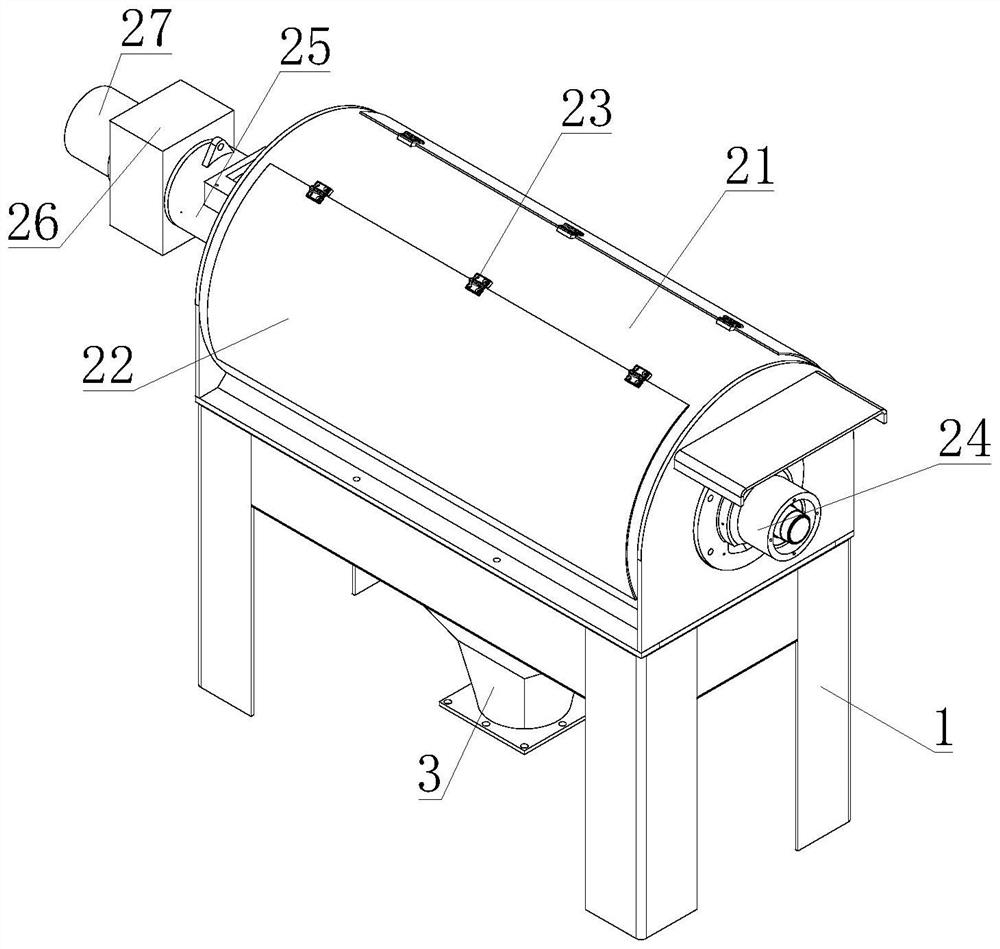

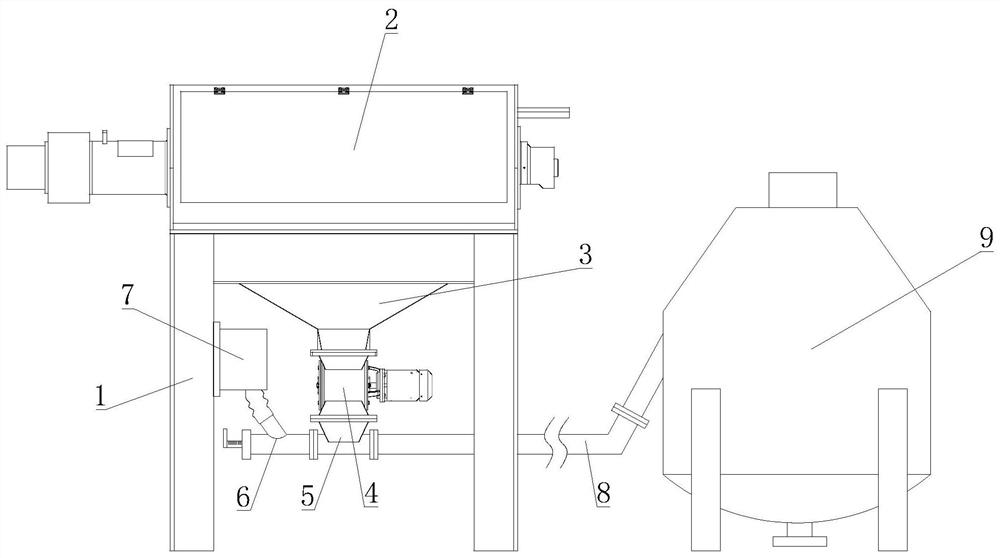

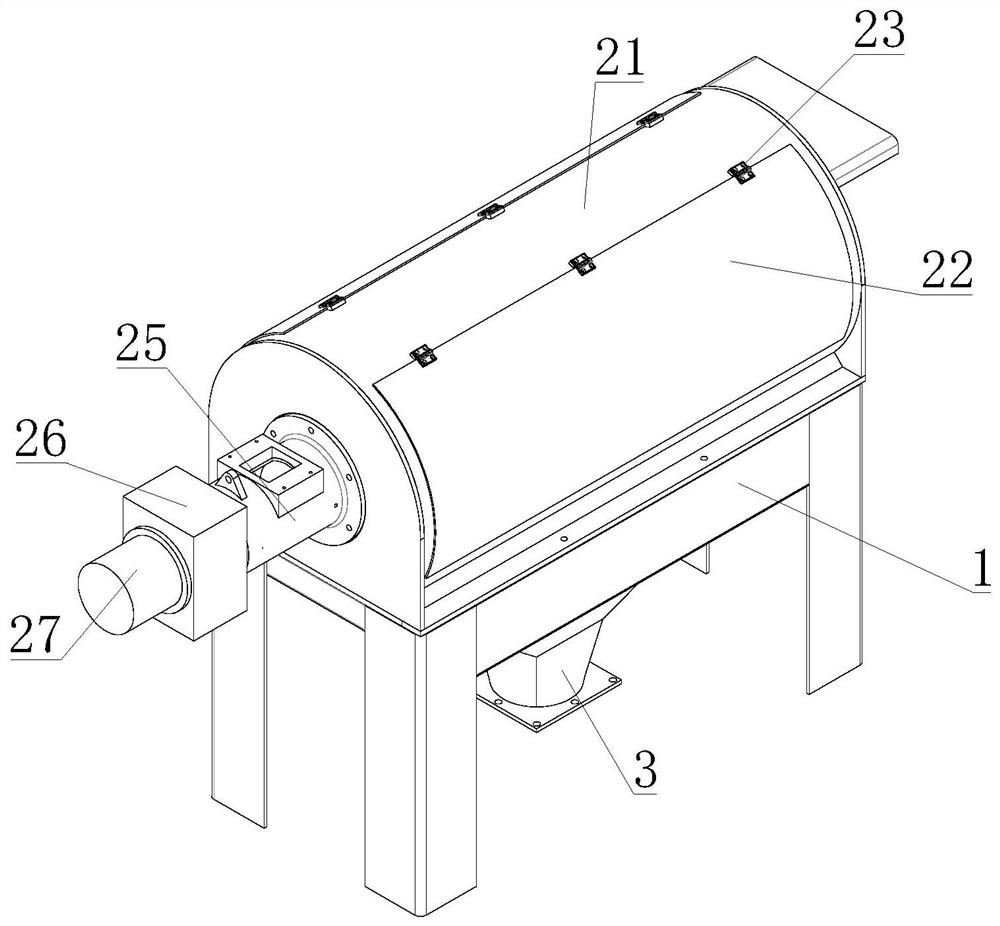

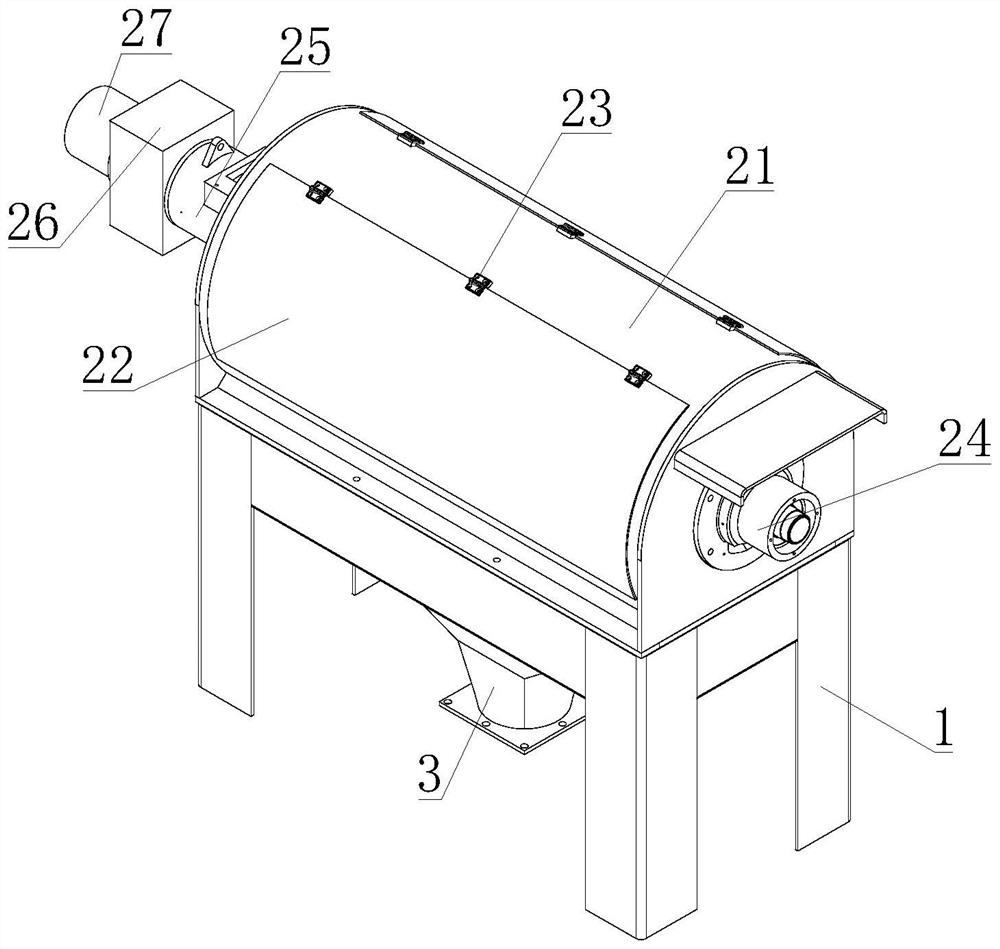

Stable-discharging feed grinding equipment and processing method thereof

ActiveCN112742535AImprove grinding efficiencyPlay a protective effectFeeding-stuffDispersed particle filtrationGear wheelControl engineering

The invention discloses stable-discharging feed grinding equipment and a processing method thereof. A grinding assembly is fixedly mounted on a main body rack and used for grinding and smashing feed, a receiving hopper is mounted at a discharging opening in the lower end of the grinding assembly, and a discharging adjusting assembly is fixedly mounted at the lower end of the receiving hopper. The working method specifically comprises the following steps that firstly, feed needing to be ground and processed is put into a feeding hopper installed on a feeding base, the feed falls into the feeding base, a first motor works to drive a gear set in a speed reducer to rotate, the speed reducer drives a grinding rod assembly to rotate, a shaft rod base drives a grinding shaft to rotate, feed is ground and conveyed through grinding spiral pieces arranged on the periphery of the grinding shaft, falling of a grinding machine is adjusted through the discharging adjusting assembly, constant-speed quantitative falling of the feed is achieved, the feed is effectively prevented from being accumulated in the receiving hopper or the grinding machine, and the evenly-falling feed can be conveniently conveyed through a conveying mechanism below.

Owner:安徽儒特实业有限公司

Preparation method of polymer fiber reinforced resin-based composite material

ActiveCN110804195AImprove consistencyImprove forming efficiencyFibre typesResin-Based CompositeUltimate tensile strength

The invention discloses a preparation method of a polymer fiber-reinforced resin-based composite material. The method comprises the following steps: (1) preparing a first mixed resin; (2) heating thefirst mixed resin and performing spraying on a fiber product with various materials; (3) performing first curing on a wet fiber product; (4) cutting the first cured fiber product into a specific shapeto form a semi-finished product; (5) preparing a second mixed resin; and (6) heating the second mixed resin and performing spraying on the semi-finished product to obtain the final polymer fiber-reinforced resin-based composite material. The preparation method provided by the invention is simple, the production cost is low, and the prepared polymer fiber-reinforced resin-based composite materialcan effectively improve interface properties, strength and toughness, and has practical application value.

Owner:吉林市东奇科技有限公司

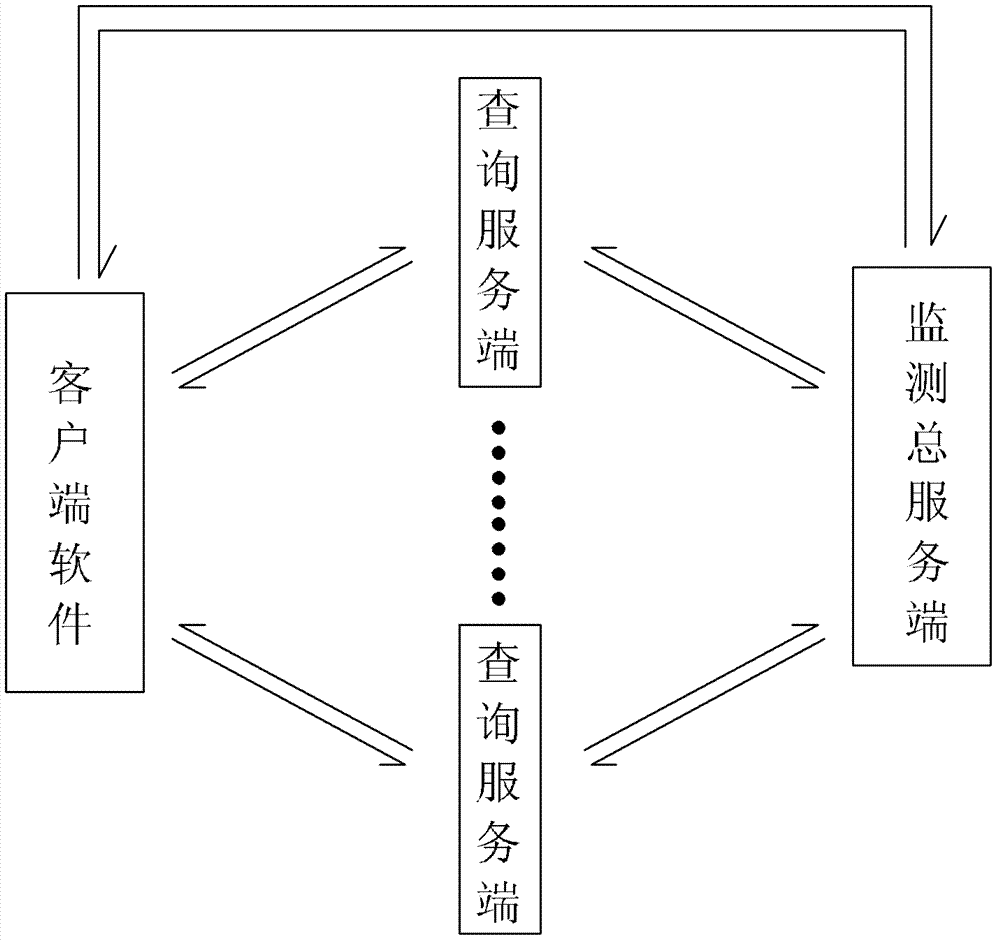

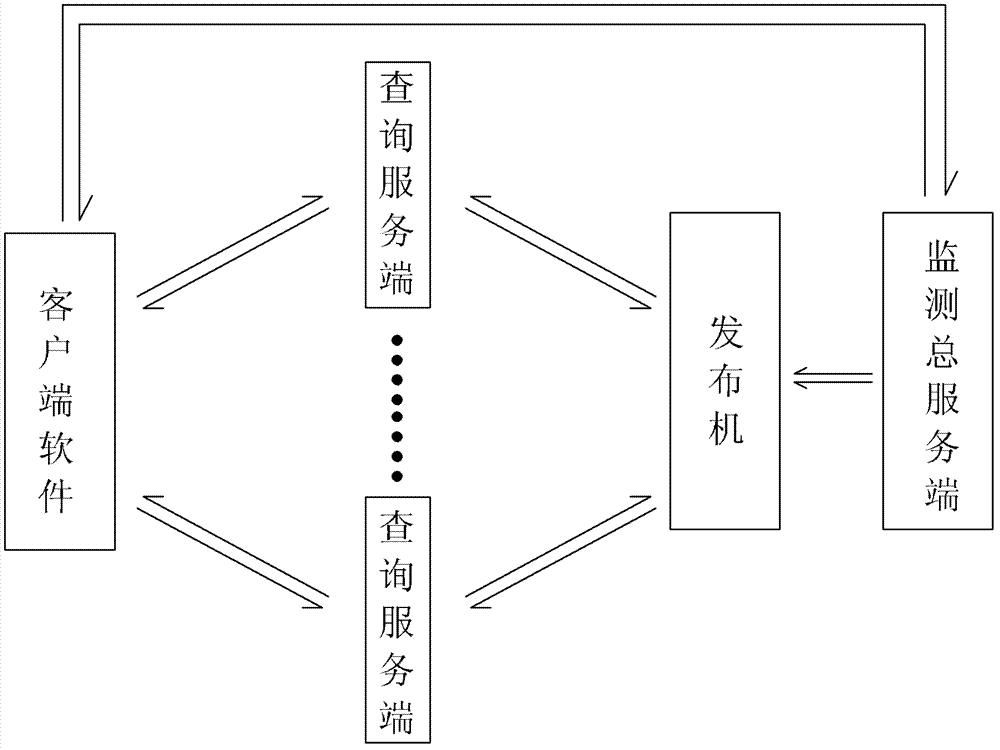

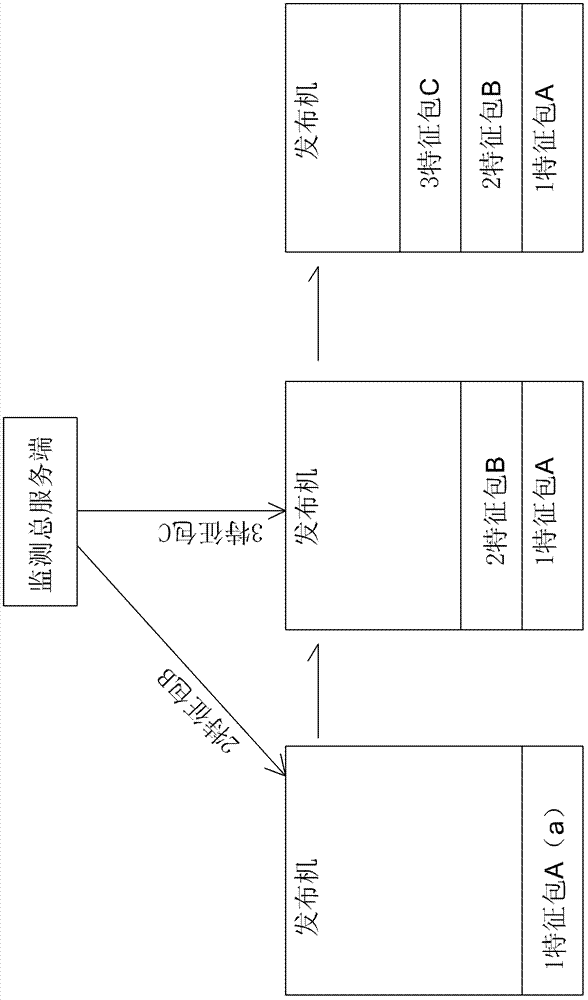

Characteristic real-time releasing system and method

The invention relates to a characteristic real-time releasing system. The characteristic real-time releasing system is characterized by comprising a general monitoring service side, a releasing machine and a query service side, wherein the general monitoring service side transmits a file characteristic packet (data packet with file characteristics) to the releasing machine; and the query service side actively access the releasing machine for downloading the file characteristic packet which is not downloaded by the query service side to the query service side. According to the characteristic real-time releasing system, the releasing machine serves as a transmission medium, and a mode for accessing the releasing machine through the query service side is adopted, and therefore, the abnormal query service side can be recovered, and a self file characteristic packet can be actively updated by the recovered query service side, a manual process is reduced, the self file characteristic packet can be timely updated, and the updating of software of a client cannot be delayed.

Owner:ZHUHAI BAOQU TECH CO LTD

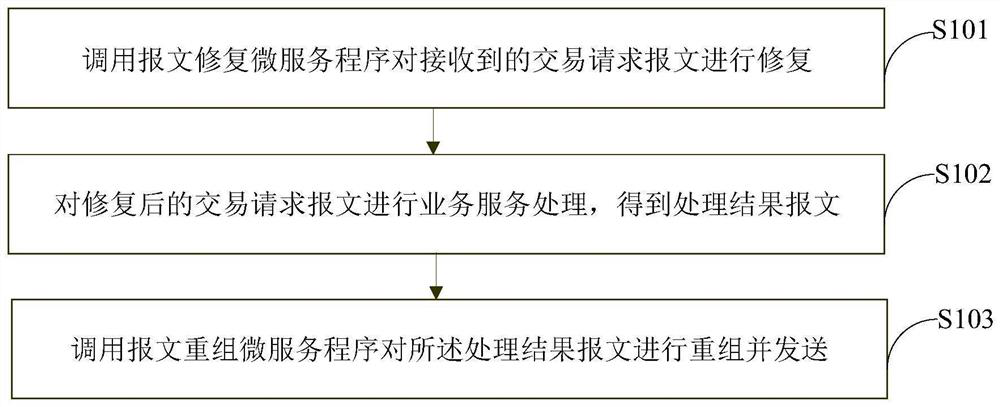

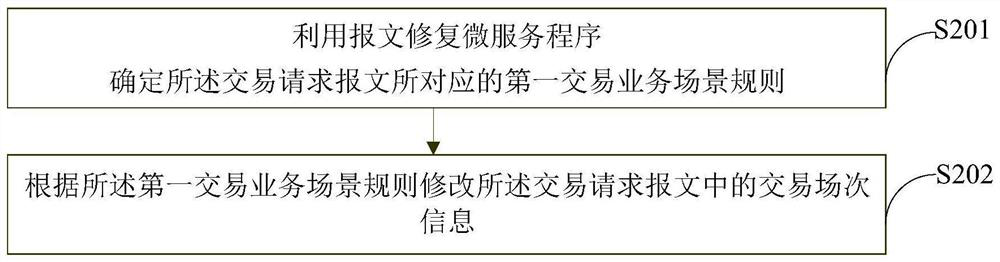

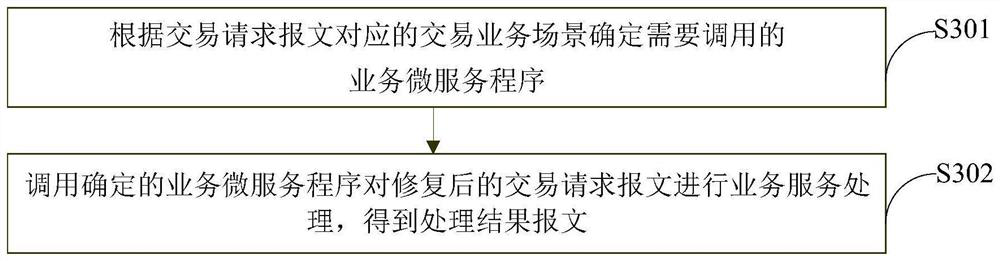

Automatic message processing method and device

PendingCN114679462AEnhanced automatic processing capabilitiesMeet specification requirementsFinancePayment architecturePaymentEngineering

The invention provides an automatic message processing method and device, belongs to the technical field of mobile internet, can be used in the financial field, and comprises the following steps: calling a message repair micro-service program to repair a received transaction request message; performing business service processing on the repaired transaction request message to obtain a processing result message; and calling a message recombination micro-service program to recombine and send the processing result message. According to the application, the transaction session information of the transaction request message in the distributed payment platform system can be flexibly restored, so that the requirement of automatic processing of the system is met.

Owner:BANK OF CHINA

A stable discharge feed grinding equipment and processing method thereof

ActiveCN112742535BImprove grinding efficiencyPlay a protective effectDispersed particle filtrationFeeding-stuffGear wheelControl engineering

The invention discloses a stable discharge feed grinding equipment and a processing method thereof. A grinding assembly is fixedly installed on the main body frame. The grinding assembly is used for grinding and pulverizing the feed. The lower end of the receiving hopper is fixedly equipped with a feeding adjustment assembly. The working method specifically includes the following steps: Step 1: Put the feed that needs to be ground into the feeding hopper installed on the feeding seat, and the feed falls into the In the feeding seat, the first motor works to drive the gear set in the reducer to rotate, the reducer drives the grinding rod assembly to rotate, and the shaft seat drives the grinding shaft to rotate, and the feed is ground and conveyed through the grinding screw set on the outer periphery of the grinding shaft. The invention adjusts the blanking of the grinder through the blanking adjustment component, realizes the uniform and quantitative falling of the feed, effectively prevents the accumulation of the feed in the receiving hopper or the grinder, and the uniformly falling feed facilitates the conveying of the feed by the lower conveying mechanism.

Owner:安徽儒特实业有限公司

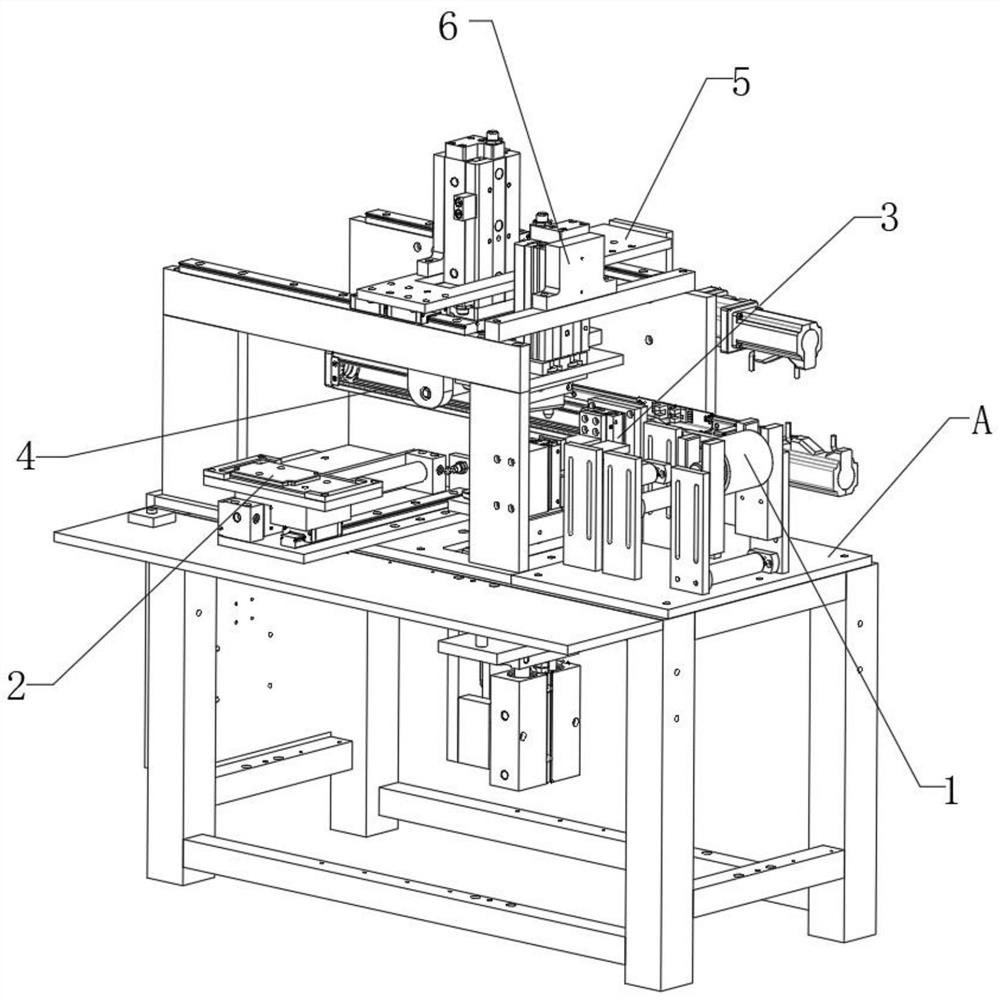

Automatic dispensing and curing all-in-one machine

InactiveCN112403832AAvoid damageNo manual operationPretreated surfacesCoatingsElectric machineEngineering

The invention discloses an automatic dispensing and curing all-in-one machine. The automatic dispensing and curing all-in-one machine comprises a dispensing device base, a control panel is fixedly installed on the side wall of the dispensing device base, a fixing frame is fixedly installed at the top of the dispensing device base, a first motor is movably installed in the fixing frame, and a rotary disc is fixedly installed at the output end of the first motor; and a stator is fixedly installed on the side wall of the rotary disc, an intermittent disc is fixedly installed in the fixing frame,and a chain wheel is fixedly connected to the side wall of the intermittent disc. According to the automatic dispensing and curing all-in-one machine, automatic dispensing and curing are adopted, manual operation is not needed, the product quality is stabilized through automatic operation, the stability of a glue dispensing gun and the accuracy of the position, the cost is saved, glue dispensing is conducted in a mode that a product can be automatically fixed, manual procedures are reduced, through an intermittent conveying mode, the product after dispensing is automatically conveyed to a curing area to be cured, manual operation is not needed, and damage of a UV lamp to a human body is reduced.

Owner:SUZHOU HUIJIAN ELECTRONICS

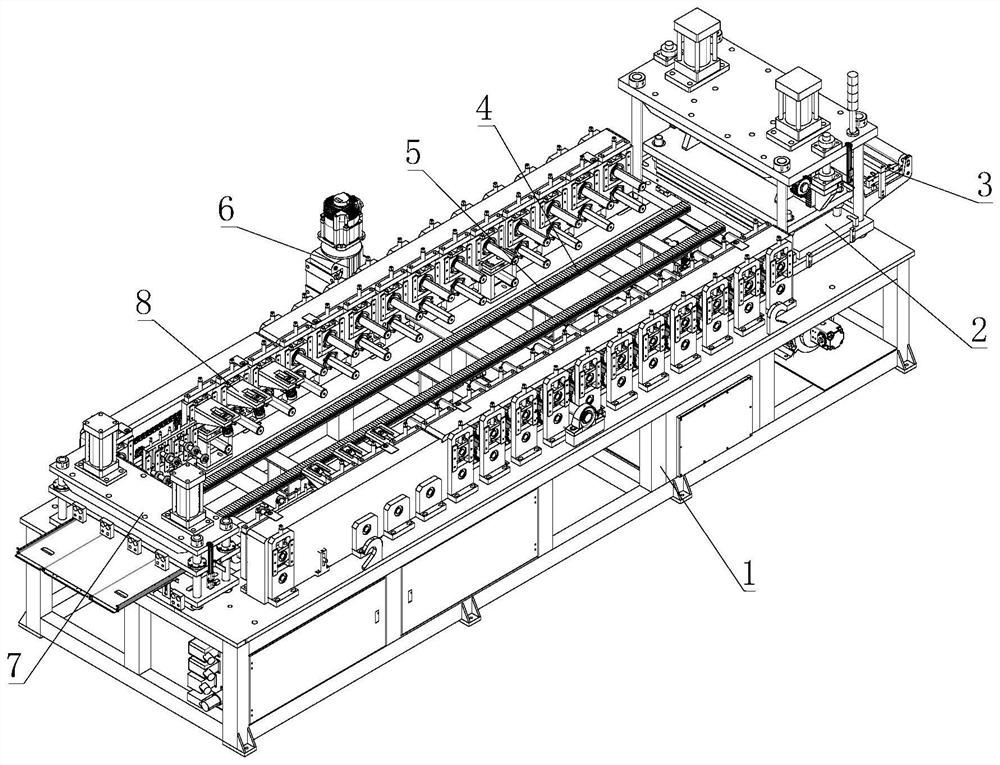

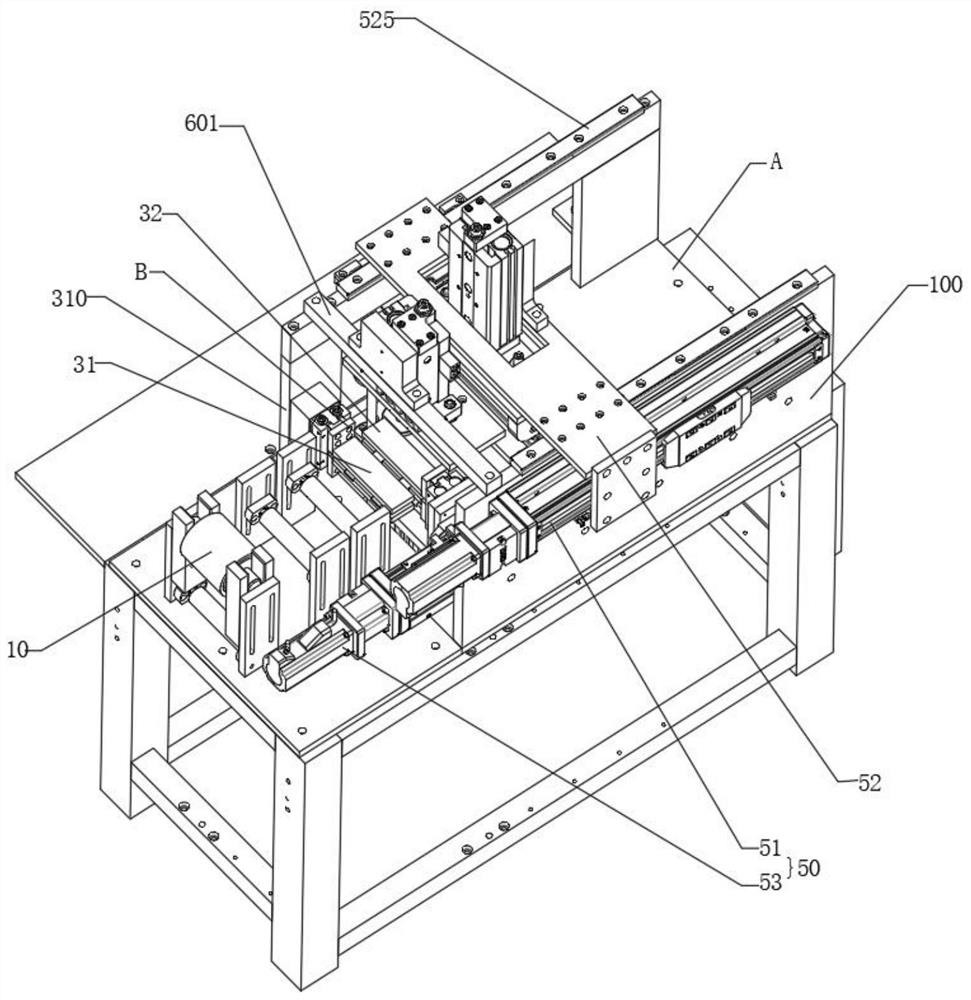

An automatic production line for forming the shell of a fire extinguisher box

ActiveCN113523813BImprove flatnessImprove processing efficiencyFire rescueOther manufacturing equipments/toolsProduction linePunching

The invention discloses an automatic production line for forming a shell of a fire extinguisher box. Two groups of conveying bars are fixedly installed on the upper end of the main frame, and several groups of evenly distributed conveying rollers are rotatably installed on the conveying bars; The drilling and chamfering assembly is used for drilling and chamfering the shell plate; the roller conveying assembly is used for rolling and folding the shell plate while conveying the shell plate; the cutting assembly is used for cutting the shell plate. The invention can realize the automatic processing of shell feeding, punching and corner cutting, rolling edge folding and cutting of the shell plate, effectively reducing the manual procedures in the processing process, reducing the processing cost and effectively improving the processing efficiency.

Owner:广东德玛士智能装备有限公司

A film sticking machine for automatically attaching the protective film of the mobile phone case

The invention proposes a film sticking machine for automatically attaching a protective film of a mobile phone case, including a workbench, on which a film feeding mechanism, a product placement mechanism, a film clamping mechanism, a film pulling mechanism, a film rolling mechanism and a film cutting mechanism are arranged. mechanism. The invention adopts multiple sets of linear modules to realize precise film cutting and positioning, ensures the accuracy of film application, reduces the generation of air bubbles and wrinkles in the process of film application, and reduces the problem of scratches on the surface of the mobile phone case; and reduces manual labor. The process improves production efficiency and reduces labor costs.

Owner:苏州第一塑胶有限公司

Key spraying jig

InactiveCN107993872AAvoid high temperature meltingAvoid key stuck problems caused by flying oilElectric switchesPulp and paper industryChromatic aberration

The invention relates to the technical field of key spraying jigs, in particular to a key spraying jig. A plurality of through holes are formed in the jig and are used for embedding keys, a fixing structure is arranged on a back surface of the jig and is used for fixing the jig, baffle blocks are arranged at openings of the through holes, a spraying passage is encircled by the baffle blocks, and the size of the spraying passage is matched with the size of a region to be sprayed on a key. The invention aims to provide the key spraying jig. With the adoption of the key spraying jig provided by the technical scheme, two processes of glue paper encapsulation and glue paper removal are reduced, the processing efficiency is improved, the situation that a key guide bone flies oil is prevented, the problem of key stuck caused by high-temperature melting of the glue paper and flying oil is prevented, the consistency of appearance chromatic aberration and film thickness is ensured by spraying ofthe whole key, and the production efficiency and the product quality are improved.

Owner:惠州商祺科技有限公司

Car sunshade screen front line sewing tooling

PendingCN109385756AReduce manual processesReduce scrap rateWork-feeding meansTextileCivil engineering

The invention discloses a car sunshade screen front line sewing tooling which comprises fabric flanging, fabric pressing, product blanking, fabric pressing, fabric bending, tooling quick replacement,platen and tooling bottom plate; the sewing tooling is characterized in that: the tooling bottom plate is a carrier for the function of fabric pressing, product blanking, cloth pressing and fabric bending. The design changes the product from manual unloading to pneumatic automatic unloading and reduces the manual operation flow.

Owner:上工富怡智能制造(天津)有限公司

Metal plate machining edge turning device for cover plate

PendingCN113523132AReduce manual processesReduce processing costsMetal-working feeding devicesPositioning devicesElectric machineryMachining process

The invention discloses a metal plate machining edge turning device for a cover plate. The metal plate machining edge turning device comprises a main body rack, wherein two sets of conveying bases are installed on the main body rack, a conveying shaft is rotatably installed on the conveying bases, a conveying belt used for feeding and conveying the cover plate is installed on the conveying shaft in a transmission mode, a conveying motor is fixedly installed on one set of conveying bases, and the output end of the conveying motor is fixedly connected with the conveying shaft; and a pushing assembly used for pushing the cover plate is installed on the main body rack, an edge turning assembly used for conducting edge turning machining on the cover plate is fixedly installed on the main body rack, a discharging conveying belt used for discharging and conveying the cover plate is fixedly installed at the end of the main body rack, and the discharging conveying belt is located at the discharging end of the edge turning assembly. Automatic conveying, feeding pushing and edge turning bending machining of the cover plate are achieved, the manual working procedures in the machining process are effectively reduced, the machining cost is reduced, and meanwhile the machining efficiency is improved.

Owner:佛山市阿玛达机械科技有限公司

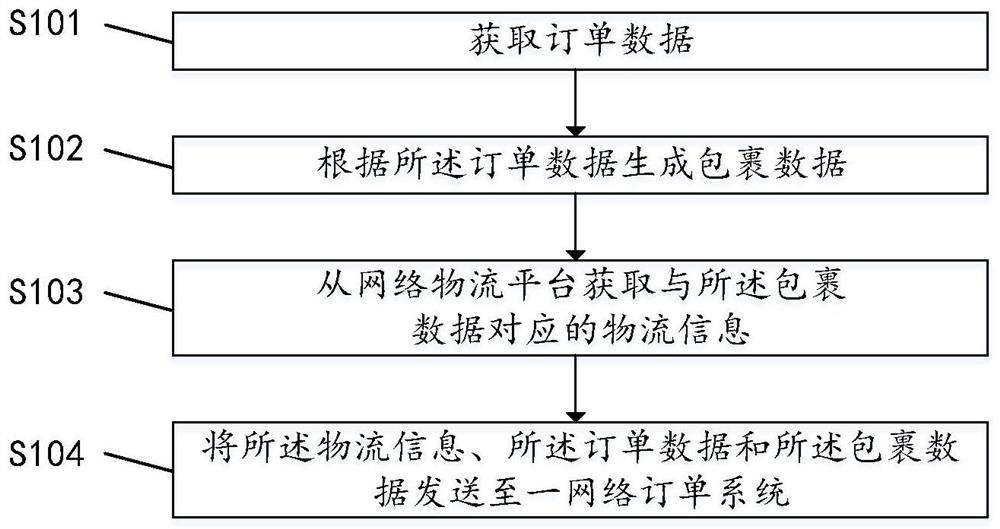

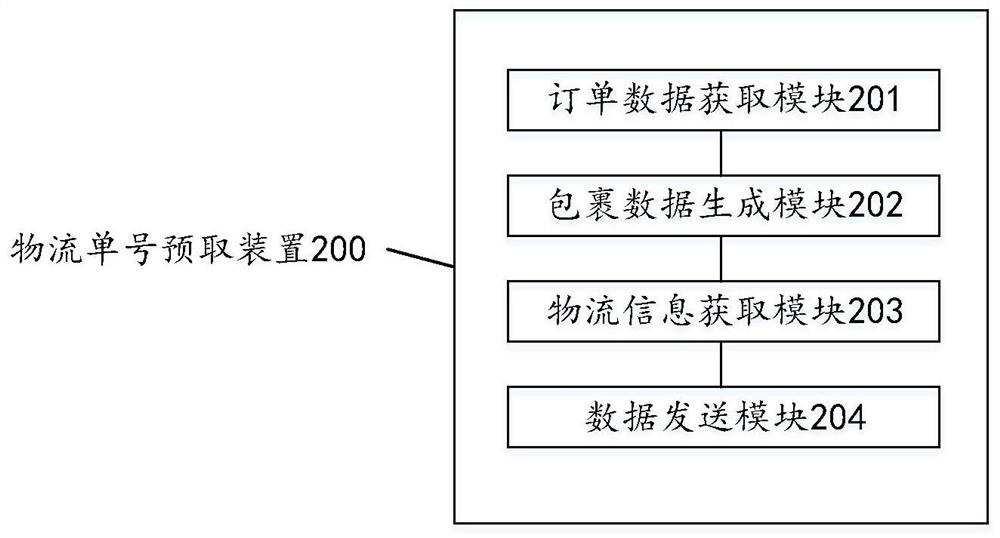

Logistics order number prefetching method, electronic equipment and storage medium

PendingCN112907185AShipping Process SimplifiedReduce manual processesBuying/selling/leasing transactionsLogisticsOrder systemService provider

The invention discloses a logistics order number prefetching method. The method comprises the steps of: obtaining order data; generating package data according to the order data; obtaining logistics information corresponding to the package data from a network logistics platform; and sending the logistics information, the order data and the parcel data to a network order system. The invention further discloses electronic equipment and a storage medium. According to the invention, the problem of how to simplify the delivery process in the e-commerce platform delivery process is at least solved, the simplification of the delivery process of the service provider is achieved, the manual operation process is reduced, and the delivery efficiency is improved.

Owner:深圳市腾辉信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com