Reduction box shell of aluminum die-casting, forming and steering system and production assembly line of reduction box shell

A production line and die-casting molding technology, which is applied in the direction of transmission box, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of low processing efficiency, high defective rate of gearbox shell, and low accuracy of manual operation. Achieve the effect of not easy to deform and save manual process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

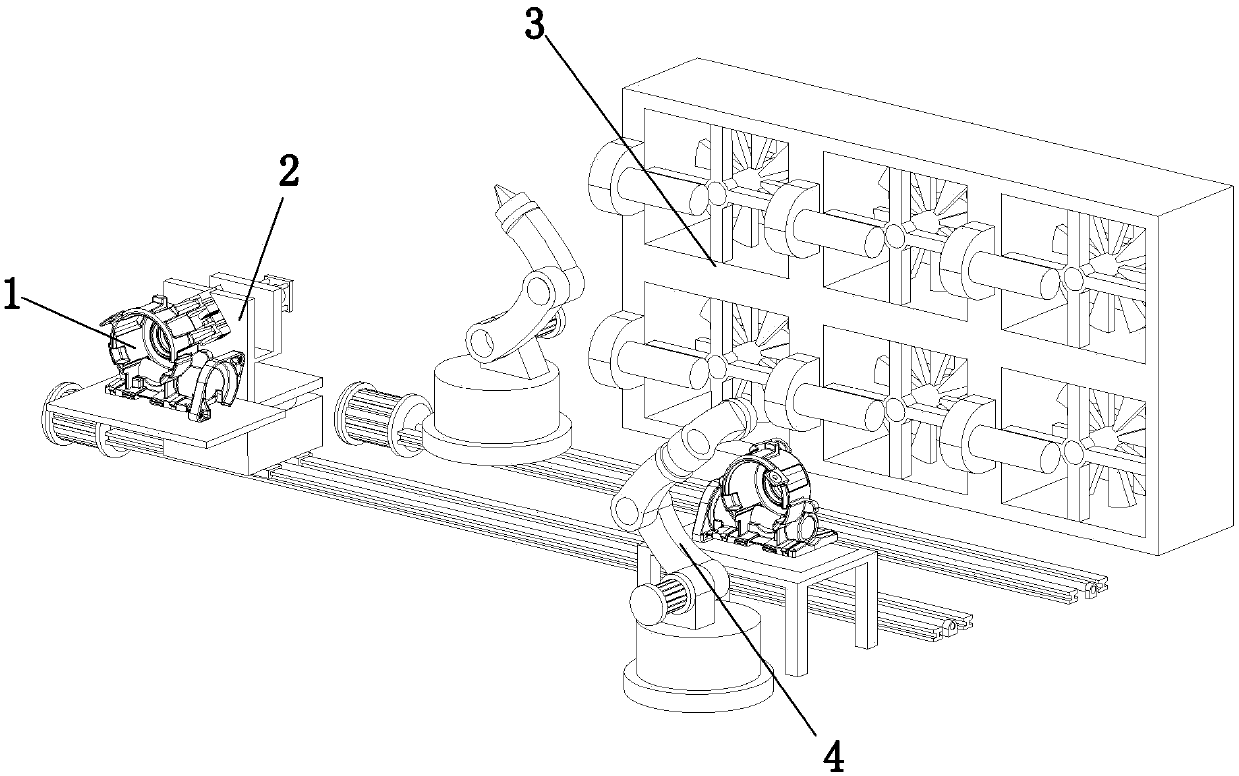

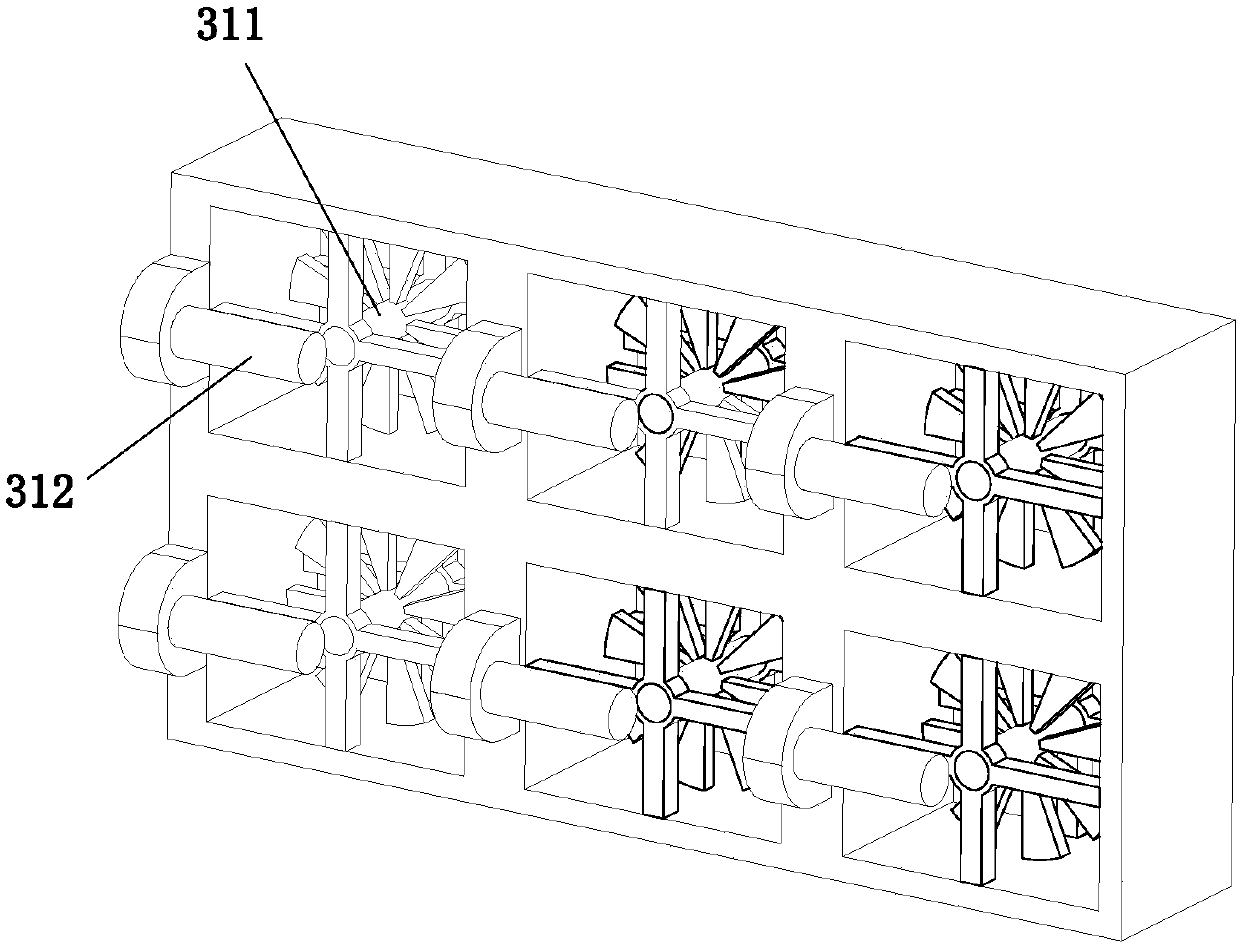

[0024] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

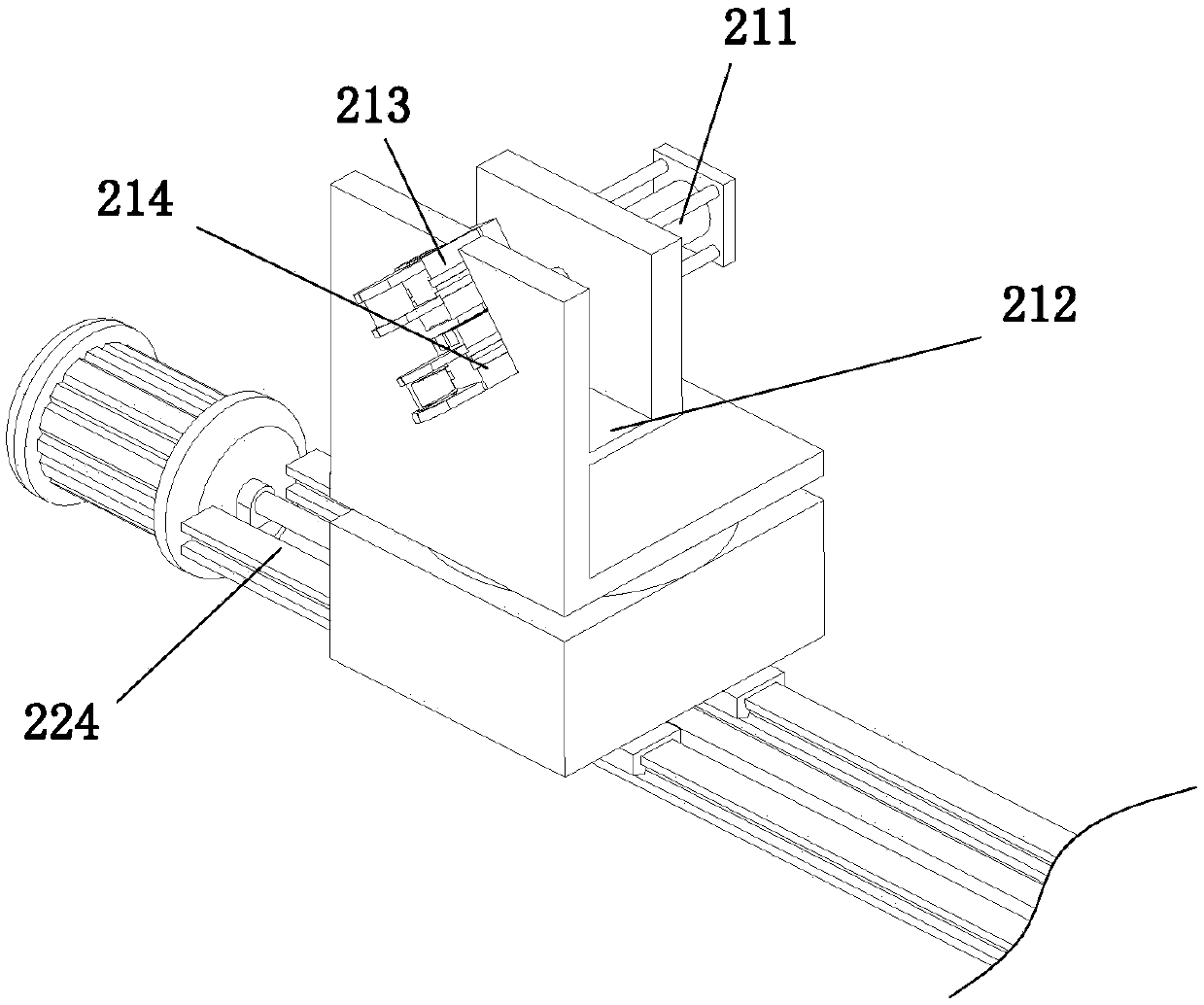

[0025] Reference Figure 1 to Figure 8 An aluminum die-casting reduction gearbox housing is shown. The reduction gearbox housing 1 includes a receiving groove 11 for accommodating a planetary gear 222 and a through hole 12 for accommodating a rotating shaft. The receiving groove 11 is cylindrical Structure, the through hole 12 is also a cylindrical structure, and the axis of the containing groove 11 is perpendicular to the axis of the through hole 12, which can ensure the stable operation of the reduction gear box housing 1.

[0026] The reduction box housing 1 is provided with an integrally formed first fixing seat 13 at the end of the through hole 12, and the reduction box housing 1 is provided with a second fixing seat 14 on the outside of the through hole 12. The plane of the first fixing seat 13 and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com