Film covering and flattening device suitable for aluminum plates with different thicknesses

An aluminum plate and lamination technology, applied in the field of aluminum plate lamination and flattening device, can solve the problems of difficult bubble treatment, poor functionality, and inability to combine together, so as to meet the needs of lamination, reduce manual processes, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

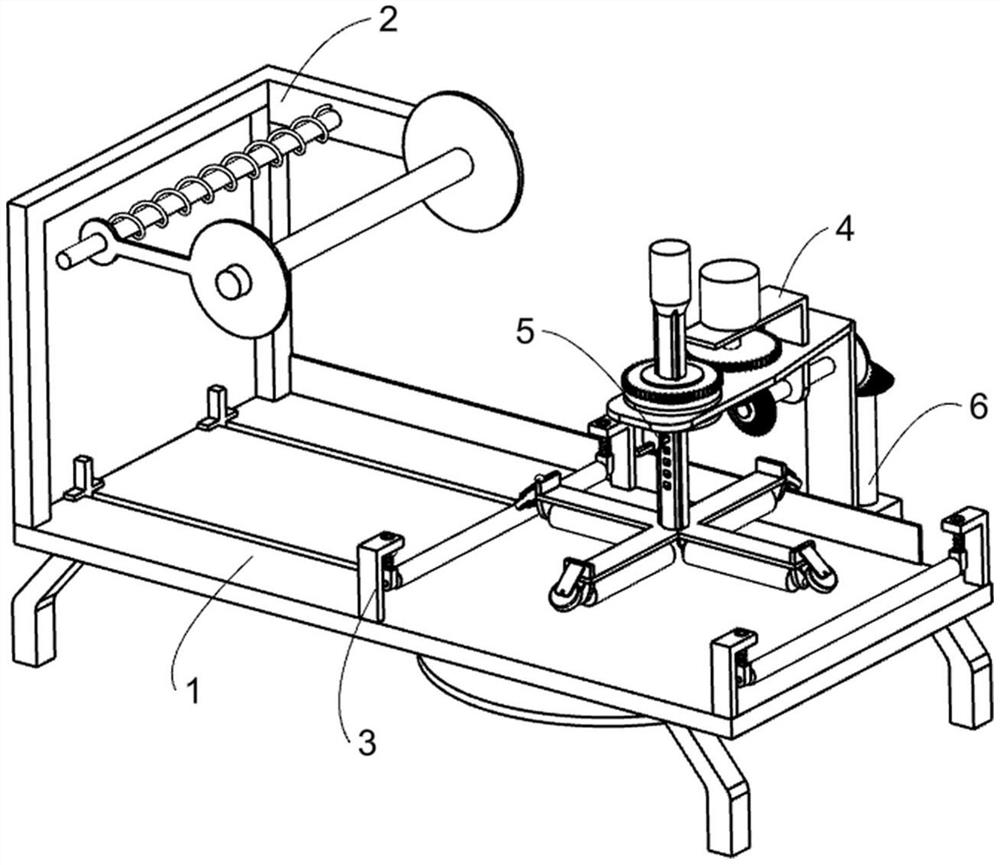

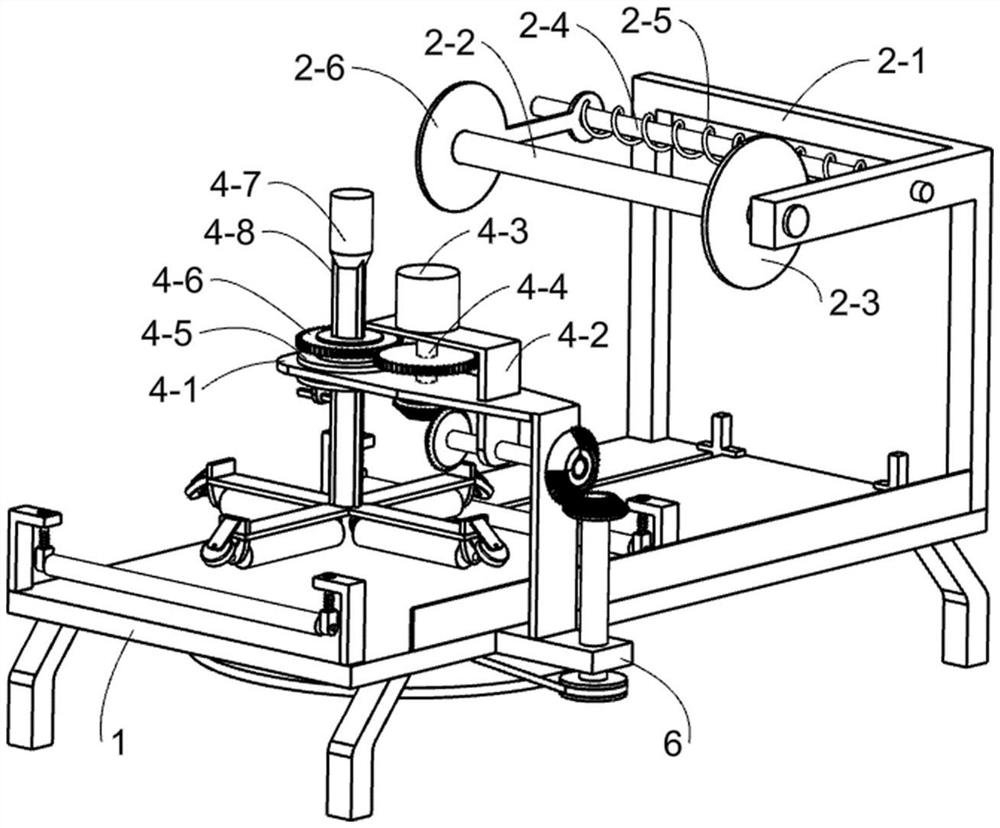

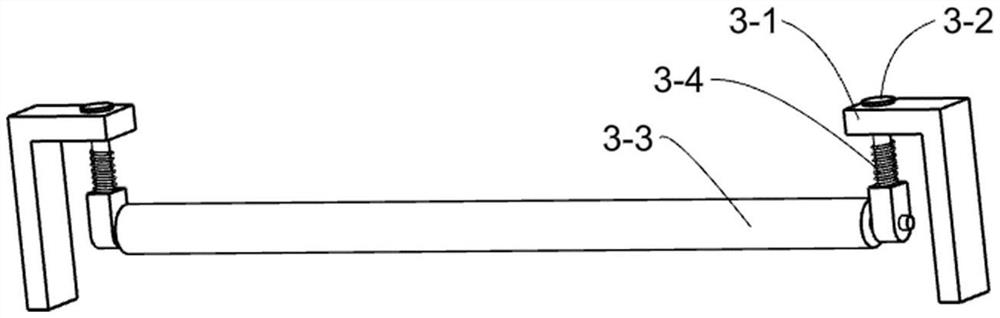

[0023] A flattening device suitable for aluminum plates with different thicknesses, such as Figure 1-6 As shown, it includes a base 1, an unwinding mechanism 2, a preliminary flattening mechanism 3, a rotary flattening mechanism 4 and an adjusting mechanism 5. The unwinding mechanism 2 for placing the film roll is located on the upper side of one end of the base 1, and is used for The preliminary flattening mechanism 3 for attaching the film to the aluminum plate is provided on the upper side of the base 1, the rotary flattening mechanism 4 for performing an omnidirectional flattening operation on the film is provided on the base 1, and the adjustment mechanism 5 is provided. on the rotary flattening mechanism 4.

[0024] Further, the unwinding mechanism 2 includes an unwinding rack 2-1, an unwinding rod 2-2, a fixed disk 2-3, a fixed rod 2-4, a tension spring 2-5 and a clamping disk 2-6. 2-1 is fixed on one end of the base 1, the unwinding rod 2-2 used to place the film wit...

Embodiment 2

[0030] On the basis of Example 1, as figure 1 and Figure 4 As shown, the adjusting mechanism 5 for adjusting the height of the rotating frame 4-9 is provided on the bottom side of the sliding ring 4-5, and the adjusting mechanism 5 includes a clamping seat 5-1 and a bolt 5-2. A bolt fixed on the bottom side of the bottom of the sliding ring 4-5 and located below the support frame 4-1, a bolt hole is provided at the lower end of the socket 5-1, and the bolt 5-2 is rotatably arranged on the socket 5-1 In the hole, one end of the bolt 5-2 can be in contact with the threaded hole on the rotating shaft 1 4-7. The bolt 5-2 is used to support and limit the rotating shaft 1 4-7. The bolt 5-2 is connected to the rotating shaft. A 4-7 coordination can adjust the position of the rotating frame 4-9, which is beneficial to the lamination and flattening operation of aluminum plates with different thicknesses.

[0031] Working principle: In order to cover different thicknesses of aluminum...

Embodiment 3

[0033] On the basis of Example 2, as Figure 1-2 , Figure 4 and Image 6 As shown, it also includes a pushing mechanism 6 for pushing the aluminum plate on the base 1. The pushing mechanism 6 is arranged on the base 1 and is connected with the rotary flattening mechanism 4. The pushing mechanism 6 includes a transmission shaft 6-1, a bevel gear One 6-2, missing angle bevel gear 6-3, rotating shaft two 6-4, bevel gear two 6-5, pulley one 6-6, rotating shaft three 6-7, pulley two 6-8, belt 6 -9, the turntable 6-10, the push frame 6-11 and the connecting rod 6-12, the transmission shaft 6-1 is set at the lower end of the support plate 4-2 through the bearing and passes through the support frame 4-1, one of the bevel gears is a 6-2 is fixed on the lower end of the power shaft 4-4, another bevel gear 6-2 is fixed on the end of the transmission shaft 6-1 close to the support plate 4-2, the two bevel gears 6-2 mesh with each other, The cutaway bevel gear 6-3 is fixed on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com