Universal precoat

A pre-coated, general-purpose technology, applied in adhesive types, film/sheet adhesives, polyurea/polyurethane adhesives, etc., can solve the problem of reducing the adhesive force of the coating layer on printed matter, Problems such as increased difficulty in laminating work, to achieve the effects of excellent bond strength, high flatness, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Take the biaxially oriented polypropylene (BOPP) general-purpose pre-coating film with a finished width of 1410 mm as an example to illustrate in detail.

[0020] 1) The configuration of the water-based adhesive for the tackifying layer. Use acrylic emulsion or polyurethane emulsion and adhesion promoter in proper proportion to prepare water-based adhesive with good bonding effect with ink.

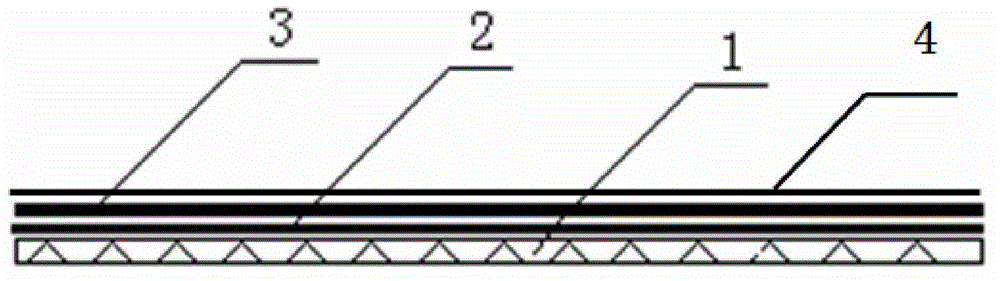

[0021] 2) see figure 1 , the finished biaxially oriented polypropylene (BOPP) universal pre-coating film has four layers, the first layer is the base material 1, the second layer is the intermediate layer 2, the third layer is the hot melt adhesive layer 3, and the fourth layer is the Tackifier layer 4. The substrate 1 is made of biaxially oriented polypropylene (BOPP) film with a width of 1430 mm; the middle layer 2 is made of polyethyleneimine (PEI); the hot-melt adhesive layer 3 is made of ethylene-vinyl acetate (EVA) hot-melt adhesive.

[0022] Using a production ...

Embodiment 2

[0023] Example 2: Taking the biaxially oriented polyester (BOPET) general-purpose pre-coating film with a finished width of 1580 mm as an example, it will be described in detail.

[0024] 1) The configuration of the water-based adhesive for the tackifying layer. Use (modified) acrylic emulsion or (modified) polyurethane emulsion and adhesion promoter in proper proportion to prepare a water-based adhesive with good ink bonding effect.

[0025] 2) see figure 1 , the finished biaxially oriented polyester (BOPET) universal pre-coating film has four layers, the first layer is the base material 1, the second layer is the intermediate layer 2, the third layer is the hot melt adhesive layer 3, and the fourth layer is the Tackifier layer 4. The substrate 1 is made of biaxially oriented polyester (BOPET) film with a width of 1600 mm; the middle layer 2 is made of polyethyleneimine (PEI); the hot-melt adhesive layer 3 is made of ethylene-vinyl acetate (EVA) hot-melt adhesive.

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com