Position regulation and control system and method applied to plasterboard production turnover

A control system and gypsum board technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of unable to achieve stable production of gypsum board specifications and dimensions, and achieve simple and convenient calculation methods, simple implementation, and improved safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

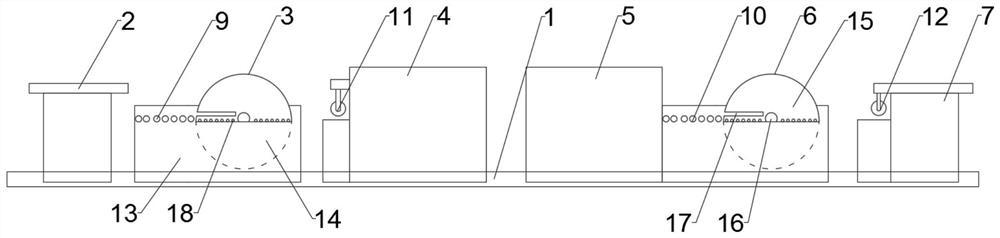

[0051] Such as figure 1 As shown, this embodiment provides a turning system for gypsum board production. In this embodiment, the turning operation and linear transfer operation are taken as a set, and the material feeding operation before coating the gypsum board is realized in a cycle, so as to ensure the quality of all gypsum boards. Face up for lamination work.

[0052] What needs to be added is that during the production process, the film covering is completed on the upper paper surface of the gypsum board, and during the production process of the gypsum board, the gypsum boards are stacked one upside down and one upside down, so it is necessary to add a flap In the workshop, the gypsum boards are turned over to ensure that the gypsum boards arriving at the coating equipment are all facing up.

[0053] It specifically includes the feeding system 2 on the track 1, the feeding flap system 3, the film coating system 4, the chasing and shearing film system 5, the blanking fla...

Embodiment 2

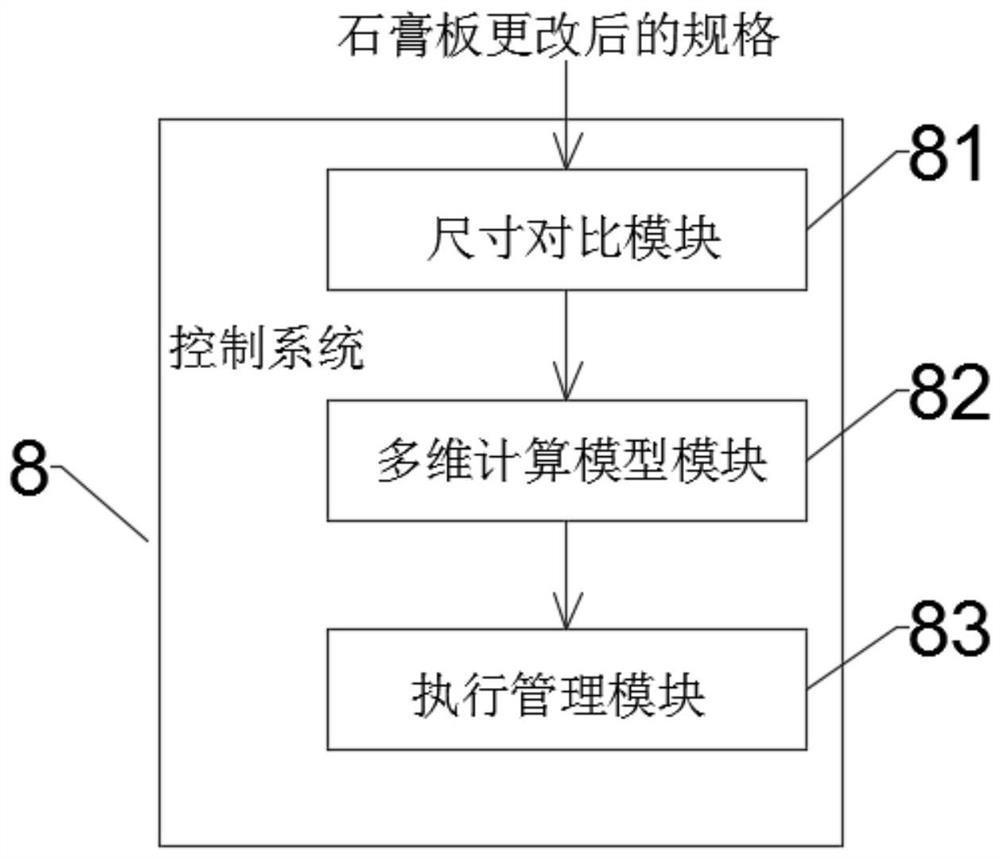

[0075] Based on the above-mentioned gypsum building material production line turnover system, such as figure 2 As shown, this embodiment also provides a position control system for a gypsum board production line, including a feeding system 2, a feeding flap system 3, a film covering system 4, a chasing and shearing film system 5, a blanking flap system 6 and The unloading system 7 is connected with the control system 8, and the control system 8 adjusts the feeding system 2, the feeding flap system 3, and the chasing and shearing film system 5 with the film covering system 4 as the center fixed point according to the selected gypsum board size specification The positions of the blanking turnover system 6 and the blanking system 7 move along the track 1 respectively.

[0076] The control system 8 adjusts the movement of the chasing and shearing film system 5 according to the length of the gypsum board to change the distance from the film covering system, and regulates the posit...

Embodiment 3

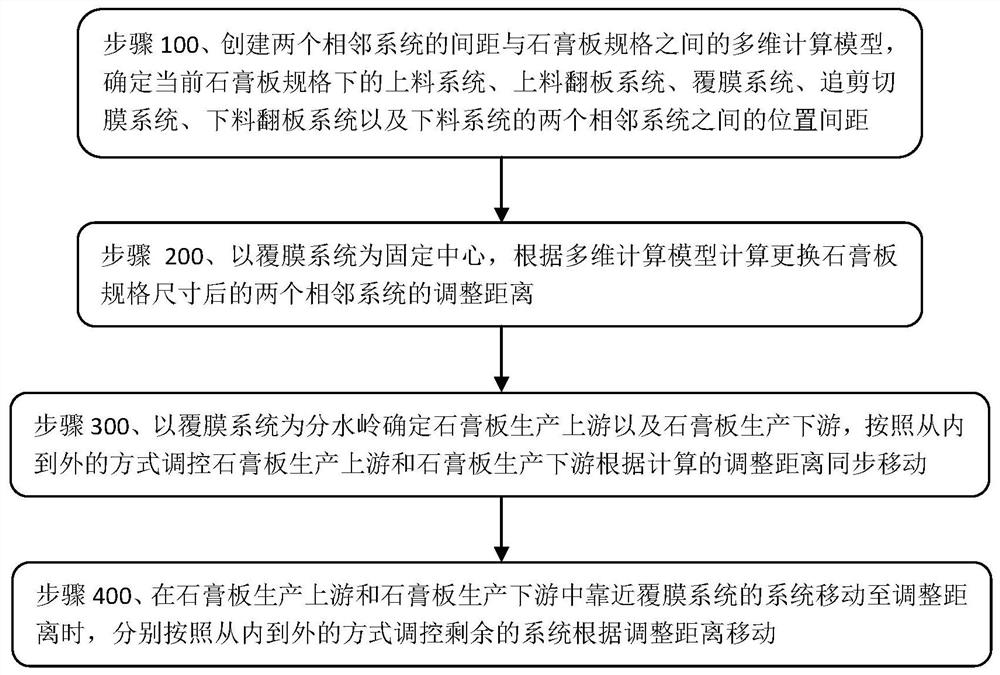

[0082] Based on the position control system of the gypsum building material production line mentioned above, such as image 3As shown, this embodiment also provides a control method for the production line position control system, including the following steps:

[0083] Step 100, create a multi-dimensional calculation model between the distance between two adjacent systems and the specifications of the gypsum board, and determine the feeding system, feeding flap system, film covering system, chasing and shearing film system, lowering system under the current gypsum board specification The position distance between the two adjacent systems of the material flap system and the unloading system;

[0084] The length of the feeding turnover system includes the length of the semicircular turning panel and the length of the input transfer roller table, and the side surface of the semicircular turning panel is provided with a cutting inner groove for clamping and turning the gypsum boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com