Car sunshade screen front line sewing tooling

A technology for sunshade curtains and tooling, which is applied to sewing equipment, sewing machine components, textiles and papermaking, etc. It can solve the problems of cumbersome engineering operations, reduced work efficiency, and a large number of manpower, and achieve the effect of reducing manual operation processes and reducing scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

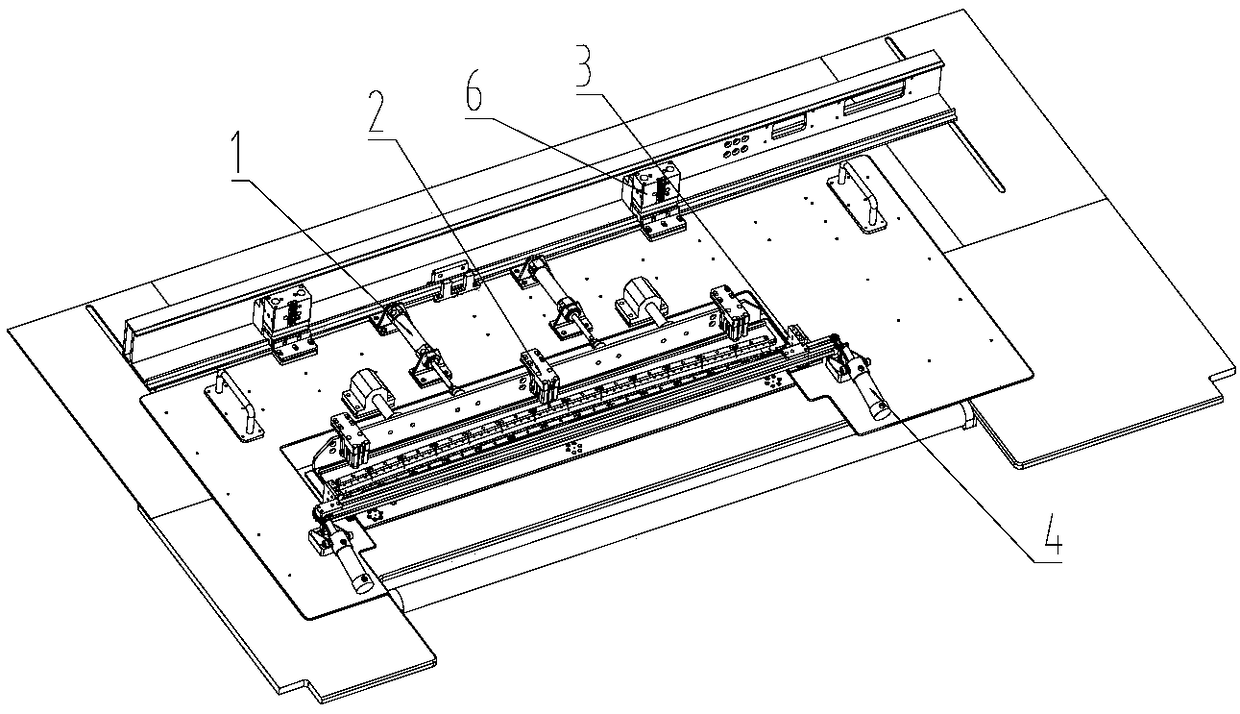

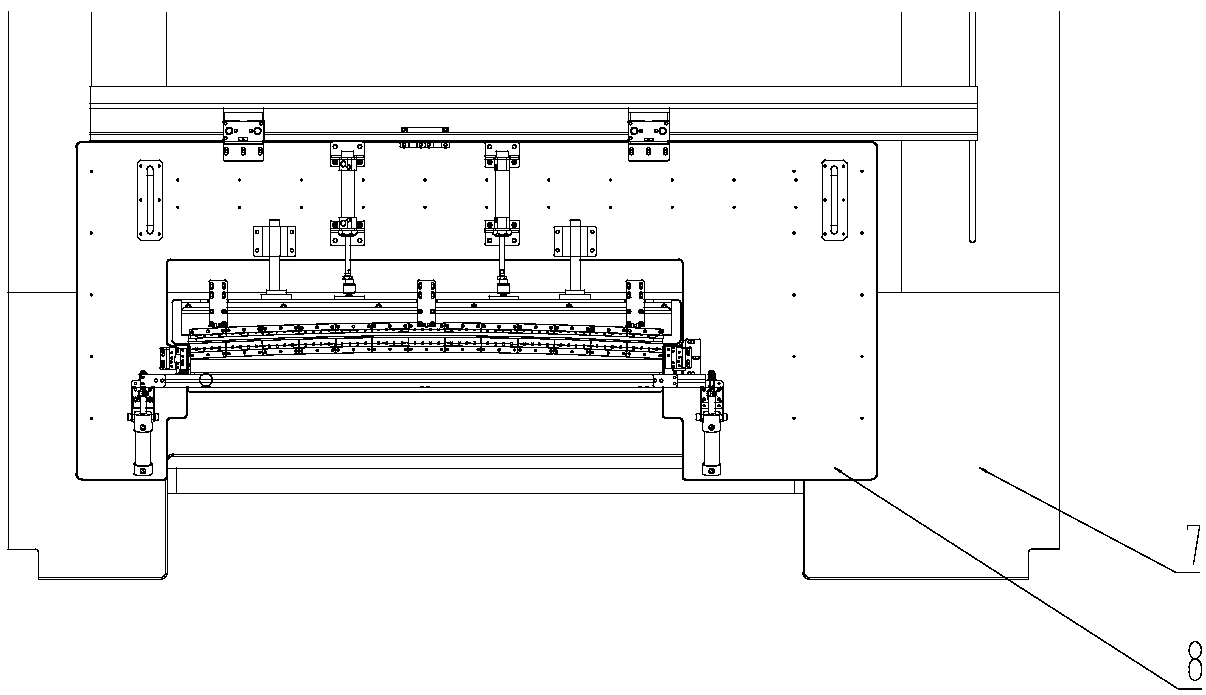

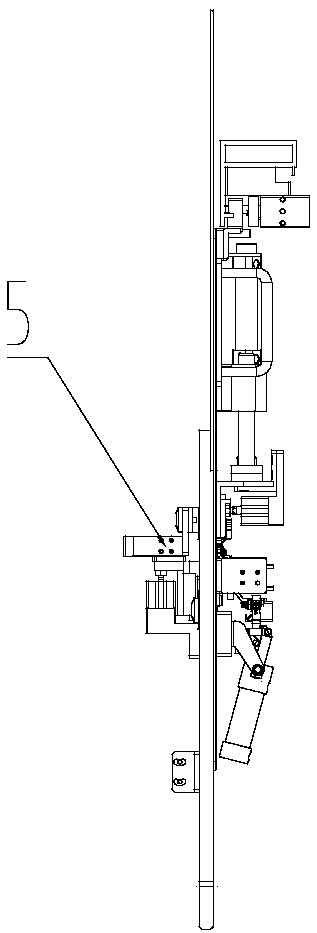

[0012] The present invention is further described below in conjunction with the accompanying drawings: the straight line sewing tooling at the front of the automobile sunshade, including fabric flanging 1, fabric hemming 2, product blanking 3, fabric pressing 4, fabric bending 5, tooling quick change 6, and platen 7. Tooling base plate 8; the tooling base plate 8 is the carrier of the functions of cloth pressing 2, product blanking 3, cloth pressing 4 and cloth bending 5; the cloth flanging 1 is responsible for folding the folded cloth Turn it into 180°; the cloth flange 2 is installed at the lower end of the cloth flange 1, and is responsible for pressing one side of the cloth after the cloth flange 1 is completed; the product blanking 3 is installed at the upper end 1 of the cloth flange, The function is to cut the material and position the product after the product is processed; the cloth pressing cloth 4 presses the cloth before the cloth bending 5 to prevent the bending si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com