Key spraying jig

A fixture and button technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of low processing efficiency and low processing quality, and achieve the effects of improving processing efficiency, ensuring consistency, and avoiding stuck keys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

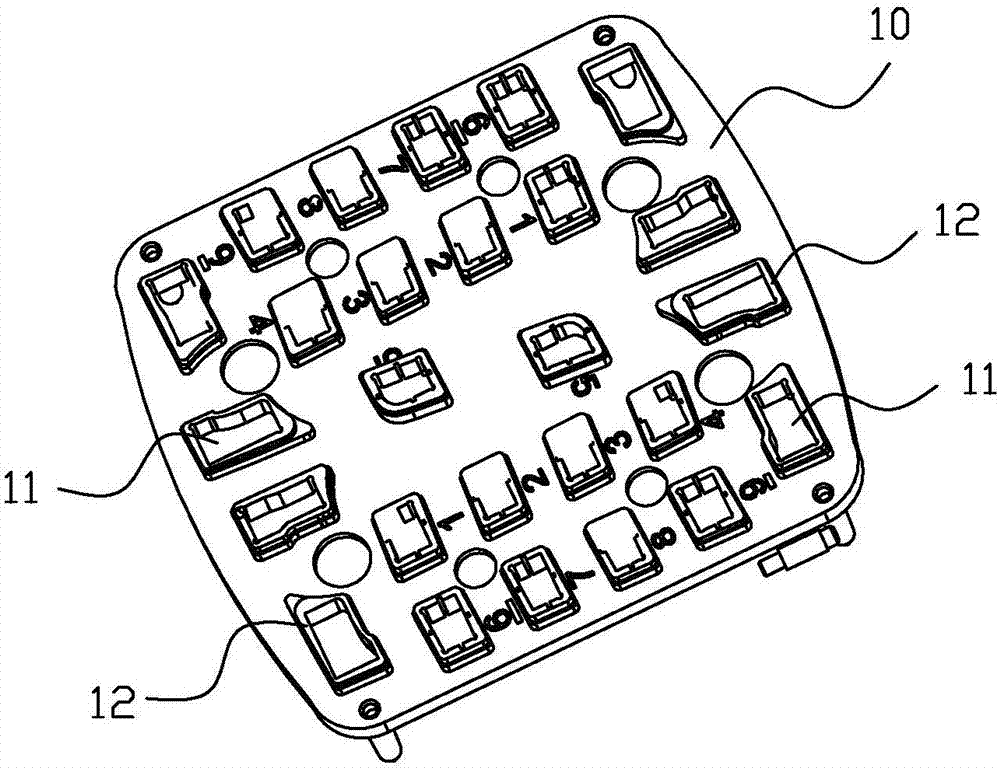

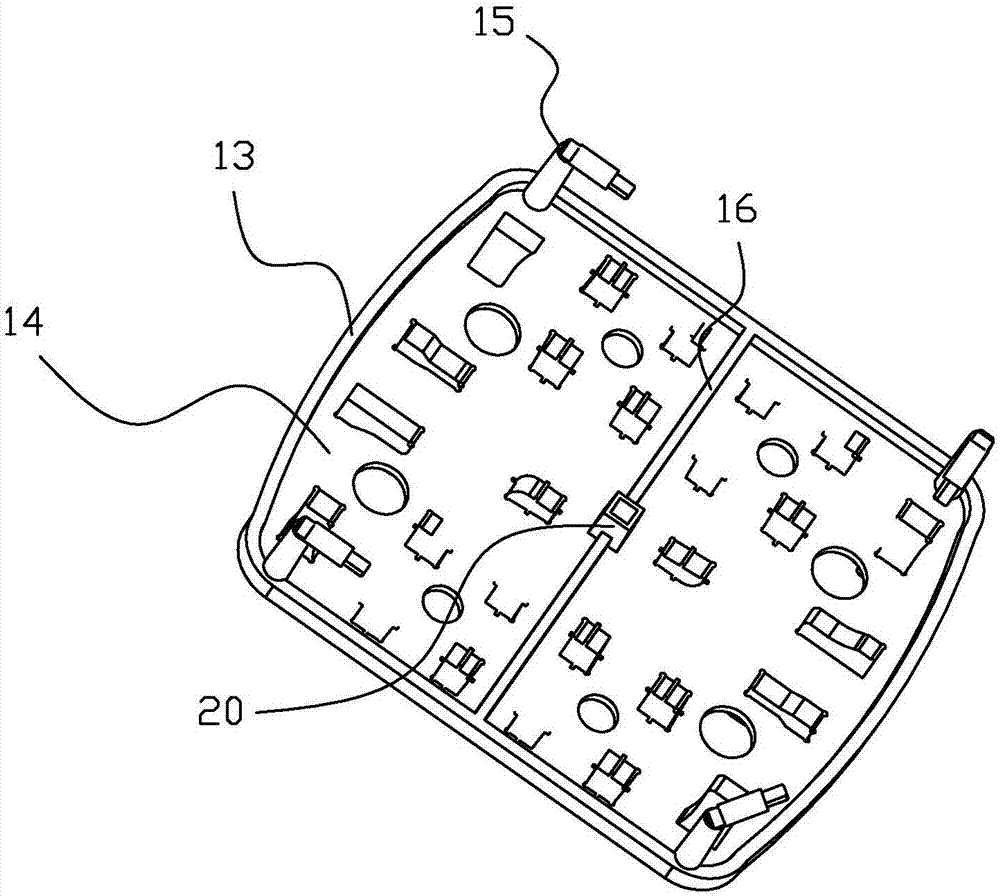

[0018] In order to improve the processing efficiency and processing quality of button spraying, such as Figure 1-2 As shown, the present embodiment provides a button spraying jig.

[0019] The spraying jig is provided with several through holes 11 for nesting keys on the jig 10. When the finished keys enter the spraying process, the keys are installed on the through holes 11, and the through holes 11 form the spraying process of key spraying. bit. The back of the jig 10 is provided with a fixing structure 20 for fixing the jig 10. After the button is installed on the through hole 11, the jig 10 is fixed on the automatic spraying line through the fixing structure 20, wherein the fixing structure 20 can be dedicated to the automatic spraying line. The clamping position, the jig 10 is fixed on the conveyor belt of the spraying automatic line through the clamping position, so as to realize the automatic spraying of the button.

[0020] During the spraying process, it is necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com