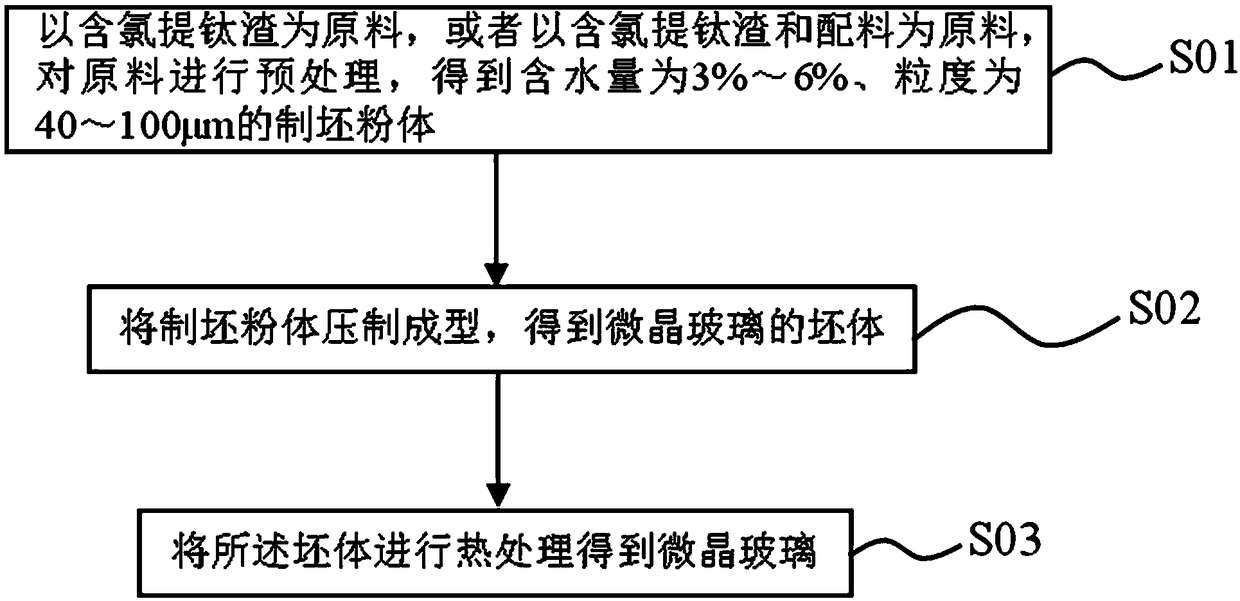

Method for preparing microcrystalline glass from chlorine-containing titanium extraction slag

A technology of glass-ceramics and titanium slag, which is applied in glass forming, glass production, glass manufacturing equipment, etc., can solve the problems of cumbersome procedures, high production energy consumption, and low utilization rate of waste slag, so as to meet the technical requirements of the process and avoid The effect of high temperature melting and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

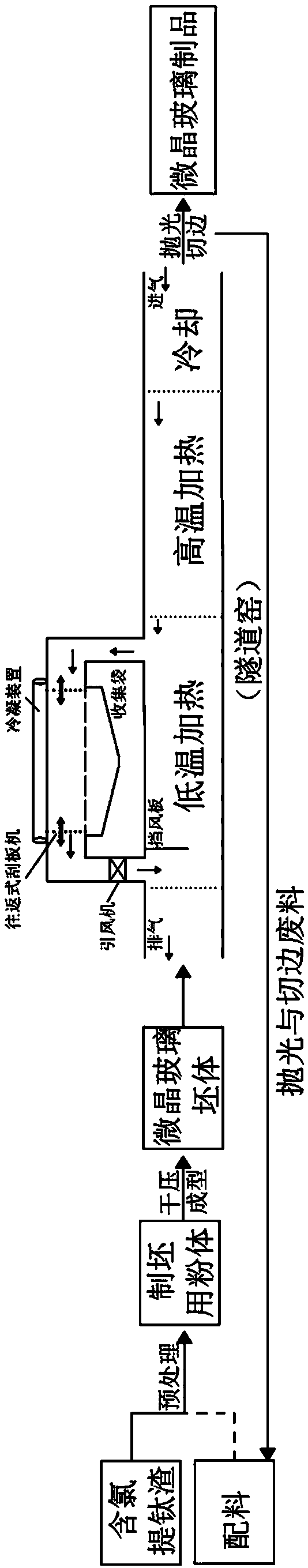

Method used

Image

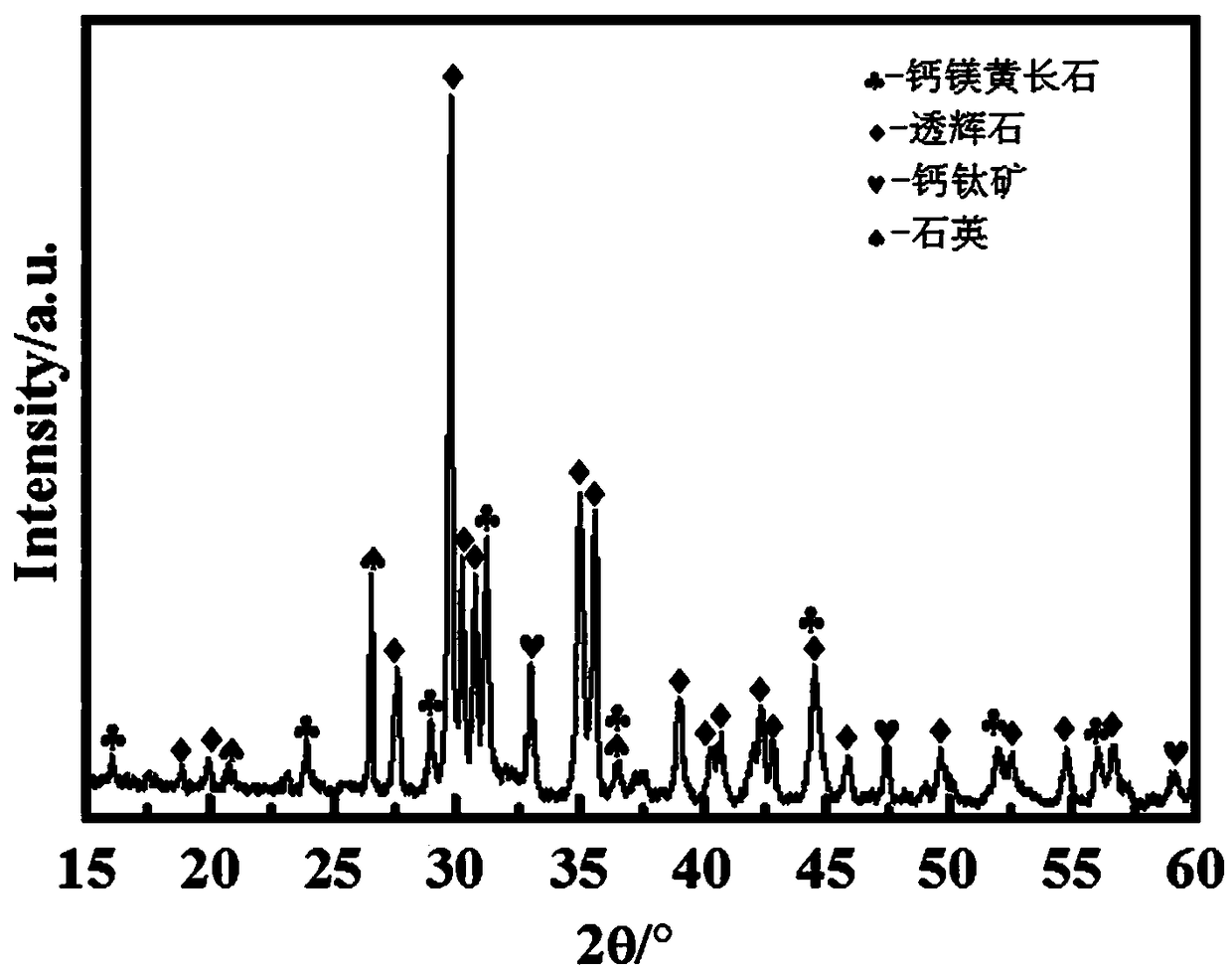

Examples

example 1

[0063] The specific preparation method is as follows:

[0064] 1) Take the chlorine-containing titanium extraction slag treated by the "high temperature carbonization-low temperature chlorination" titanium extraction process from a certain place in Sichuan as the main raw material. The ingredients are quartz, potash feldspar and borax. Dry for 8 hours in a drying room at 105°C, and then crush, grind, and classify. The components are 85% chlorine-containing blast furnace slag (chlorine-containing titanium extraction slag), quartz 5%, potash feldspar 7%, and Borax 3% was weighed and blended, and a powder with a particle size of 96 μm was used as the powder for billet making.

[0065] 2) Evenly spread the powder for billeting into the mold without adding granulating agent and binder. Under the press, the pressure is 714kgf / cm 2 , The pressing conditions of the holding time of 20s are dry-pressed and then demolded to obtain the glass-ceramic body.

[0066] 3) Put the glass-ceramic body ...

example 2

[0069] The specific preparation method is as follows:

[0070] 1) Using the chlorine-containing titanium extraction slag in Example 1 as all raw materials, the chlorine-containing titanium extraction slag is dried in a drying room at 110°C for 12 hours, then crushed, ground, and classified, and the powder with a particle size of 96μm is used as a preform Powder.

[0071] 2) Place the powder for billeting flat in the mold, using a press, at a pressure of 510kgf / cm 2 , Dry pressing and forming under the condition of 20s holding pressure, and then demolding, to obtain the glass-ceramic body. No granulating agent and binder are added during the forming process of the glass-ceramic body.

[0072] 3) Put the glass-ceramic body into the tunnel kiln, set the heat treatment program and parameters, specifically: increase the temperature from room temperature to 890°C at a temperature rise rate of 5°C / min, hold for 30 minutes; then set the temperature at 3°C / min The heating rate is increased ...

example 3

[0075] The specific preparation method is as follows:

[0076] 1) The chlorine-containing titanium extraction slag, quartz and nepheline are placed in a drying room at 108°C for 8 hours, and the components are weighed and blended according to mass percentages of 85% chlorine-containing blast furnace slag, 10% quartz, and 5% nepheline , And then crushed, pulverized, and classified to obtain a particle size of 75μm.

[0077] 2) Place the powder for billeting evenly and flatly in the mold, using a press, at 357kgf / cm 2 Under pressure, hold the pressure for 15s for dry pressing, and then demold to obtain the glass-ceramic body. No granulating agent and binder are added during the forming process of the glass-ceramic body.

[0078] 3) Put the glass-ceramic body into the tunnel kiln, set the heat treatment procedure and parameters, specifically: increase from room temperature to 950°C at a heating rate of 5°C / min, hold for 30 minutes; then set the heat treatment at 3°C / min The heating ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com