Mobile phone glass cover plate fine carving machine

A technology of glass cover and fine engraving machine, which is applied in engraving, decorative arts, stone processing tools, etc., can solve the problems of pattern melting, reduction of processing area, poor molding effect, etc., to facilitate loading and unloading, improve processing efficiency, The effect of convenient picking and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

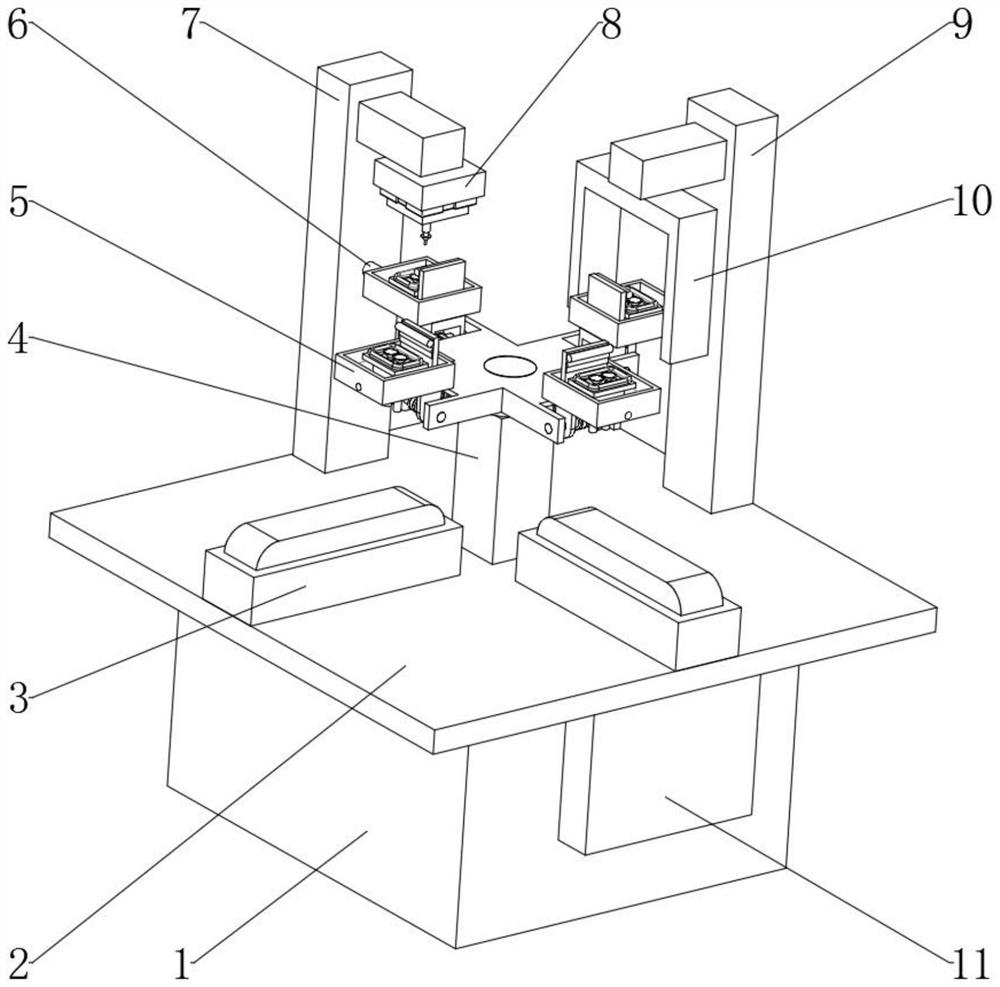

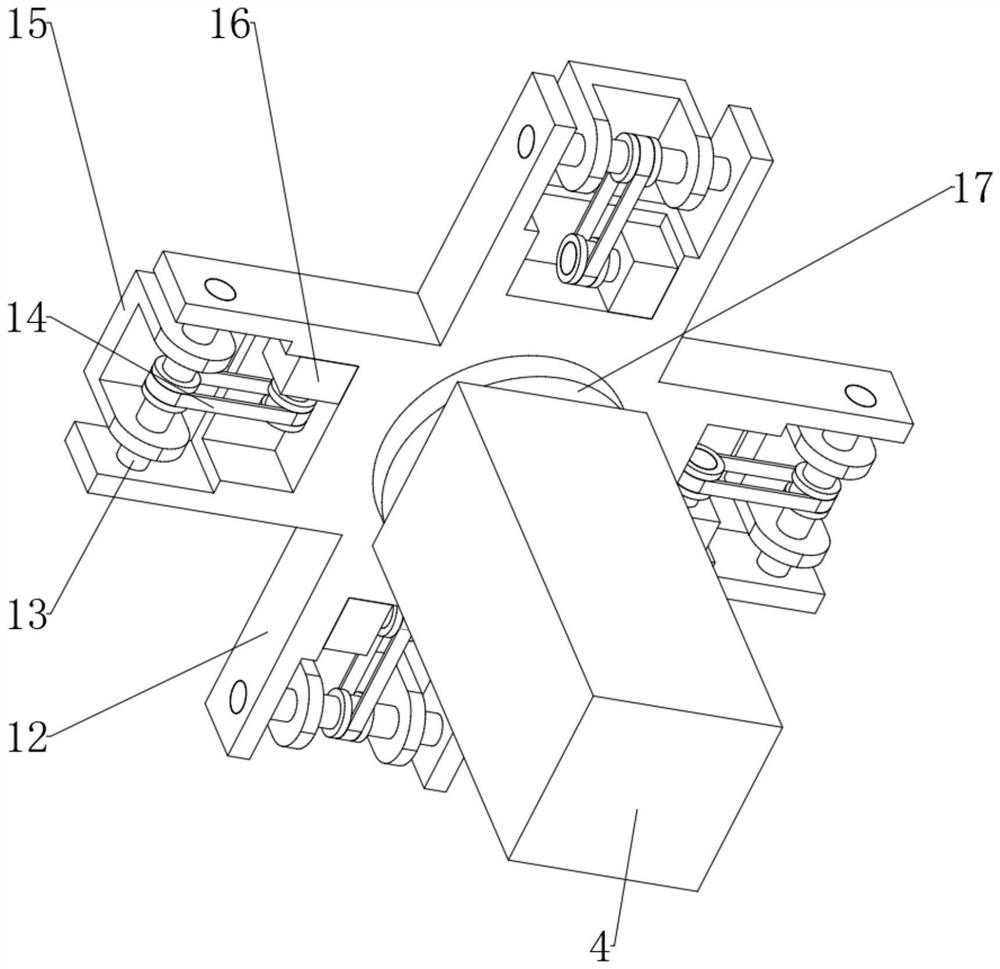

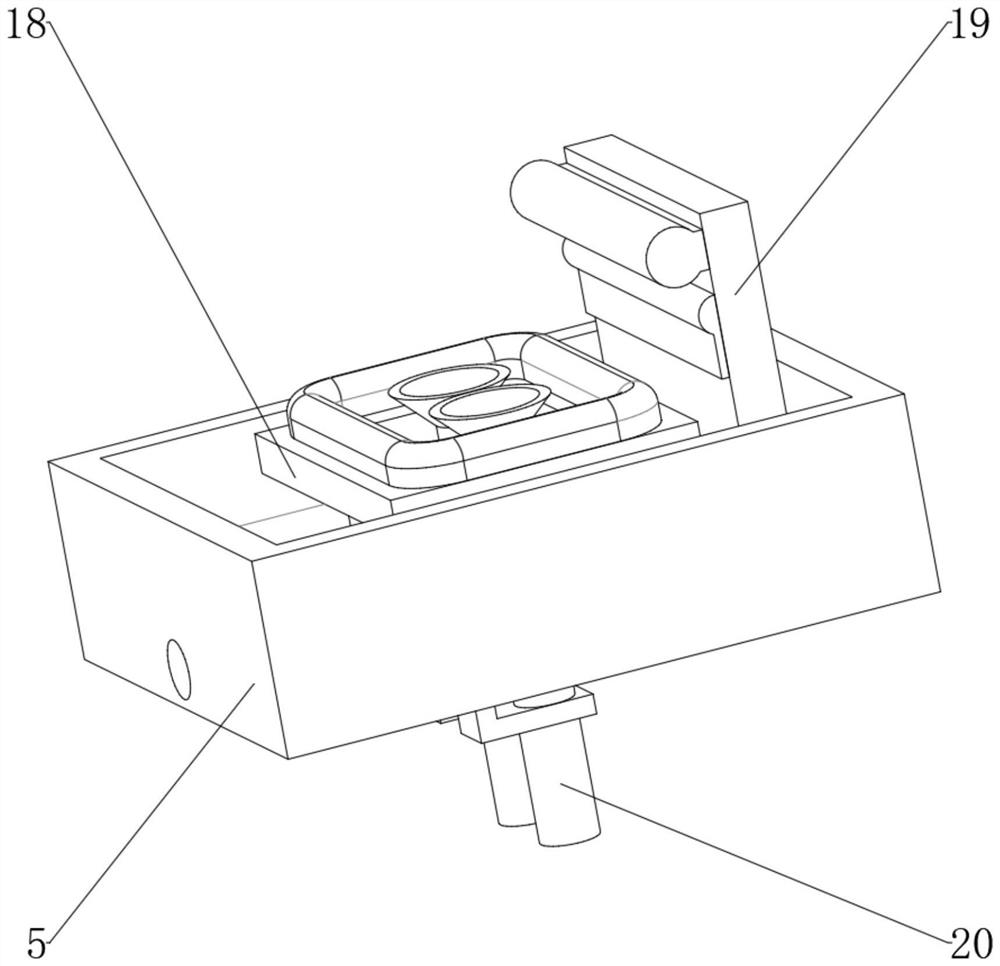

[0027] Such as Figure 1-Figure 6 As shown, a mobile phone glass cover engraving machine provided in this embodiment includes a setting plate 2 and four retention shells 5 arranged on its upper part. The outer wall of the top of the setting plate 2 is fixedly connected with a first lifting frame 7. The outer wall of the bottom of the lifting frame 7 is fixedly connected with a high-pressure chamber 8, and the outer wall of the bottom of the high-pressure chamber 8 is fixedly connected with more than three first spray boards 28 and second spray boards 29. The second spray board 29 is an L-shaped structure and is connected with the first spray board. 28 is a staggere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com