Electric tailgate driving system and control method

A drive system and tailgate technology, which is applied to doors, door/window accessories, power control mechanisms, etc., can solve the problems of difficult electric tailgate products, difficult installation, and low cost performance, so as to facilitate heat dissipation and waterproof, improve The effect of stability and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

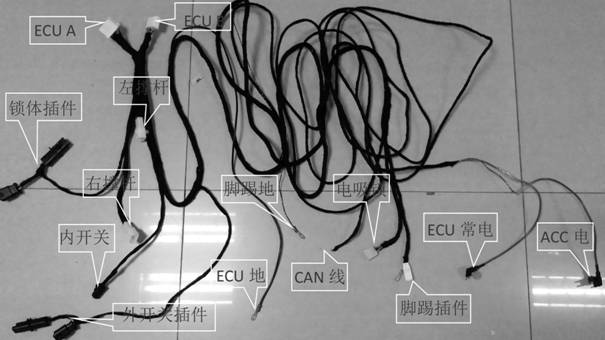

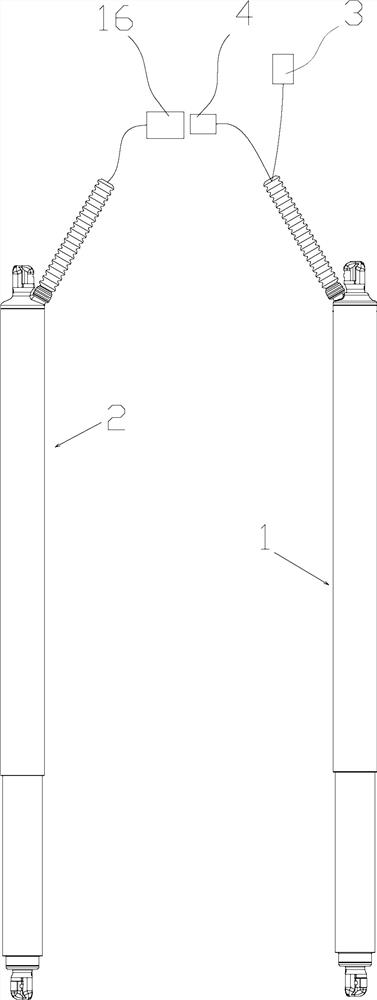

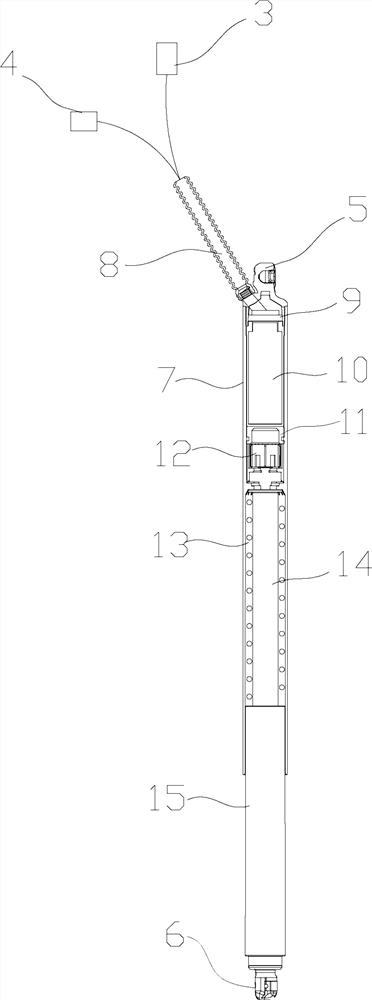

[0048] An electric tailgate driving system, which includes an electronically controlled balance bar 1 and a driving bar 2, and an ECU module 10 is arranged in the electronically controlled balance bar 1;

[0049]A wire harness connector 3 is also provided, and the wire harness connector 3 is electrically connected to the ECU module 10 through the wire harness. The wire harness connector 3 is used to connect the vehicle controller to receive instructions and power input from the vehicle controller; Commands are delivered via CAN or CAN FD protocol.

[0050] The electronically controlled balance bar 1 is connected to the driving bar 2 through a wire harness, the ECU module 10 is used to drive the driving bar 2 to move, and the electronically controlled stabilizing bar 1 moves along with the driving bar 2 . With this structure, the combination of the driving rod 2 and the electronically controlled balance rod 1 is used to expand the installation space of the ECU module 10, and th...

Embodiment 2

[0073] A control method using the above electric tailgate drive system, comprising the following steps:

[0074] S1. The vehicle controller sends an opening or closing command to the ECU module 10;

[0075] The opening or closing command includes the activation of the driving rod 2, the control of the rotation direction, the speed adjustment, the opening angle or the stroke command;

[0076] S2. The ECU 10 converts the opening or closing command into a PWM control command of the Hall motor 17, and the PWM control command includes starting, rotation direction control, speed adjustment, opening angle or stroke command of the Hall motor 17;

[0077] When approaching the two ends of the stroke of the driving rod 2, the speed of the Hall motor 17 is relatively slow, and the corresponding speed of opening and closing of the door becomes slow;

[0078] When the driving rod 2 is in the middle of the stroke, the Hall motor 17 rotates relatively fast, so as to shorten the time used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com