Ultrathin double-sided nano-silver capacitive screen and preparation method thereof

A nano-silver, capacitive screen technology, applied in the field of capacitive screens, can solve problems such as low touch sensitivity, low production efficiency, and cumbersome processes, so as to improve the touch experience effect, reduce manual operation errors, and simplify the process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

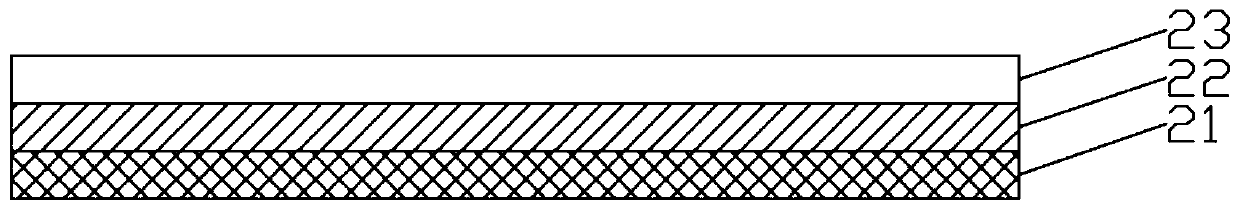

[0030] An ultra-thin double-sided nano-silver capacitive screen, such as figure 2 Shown, comprise double-sided nano-silver film 21, OCA adhesive layer 22 and glass cover plate 23, described double-sided nano-silver film comprises base material and double-layer conductive layer, and described conductive layer material is nano-silver, and described base material for PET.

[0031] A method for preparing an ultra-thin double-sided nano-silver capacitive screen. On a double-sided nano-silver film, an OCA adhesive layer is laminated roll-to-roll and covered with a glass cover. The double-sided nano-silver film is prepared by roll-to-roll laser etching. become.

[0032] Further, the preparation method of described two-sided nano-silver film comprises:

[0033] (1) adopting wet coating conductive material on the base film to prepare the double-sided nano-silver conductive film;

[0034] (2) laser etching out conductive circuit patterns on the double-sided nano-silver conductive fi...

Embodiment 2

[0038] An ultra-thin double-sided nano-silver capacitive screen, comprising a double-sided nano-silver film 21, an OCA glue layer 22 and a glass cover plate 23, the double-sided nano-silver film includes a base material and a double-layer conductive layer, and the conductive layer material It is nano silver, and the base material is PC.

[0039] A method for preparing an ultra-thin double-sided nano-silver capacitive screen. On a double-sided nano-silver film, an OCA adhesive layer is laminated roll-to-roll and covered with a glass cover. The double-sided nano-silver film is prepared by roll-to-roll laser etching. become.

[0040] Further, the preparation method of described two-sided nano-silver film comprises:

[0041] (1) adopting wet coating conductive material on the base film to prepare the double-sided nano-silver conductive film;

[0042] (2) laser etching out conductive circuit patterns on the double-sided nano-silver conductive film;

[0043] (3) making double-sid...

Embodiment 3

[0046] An ultra-thin double-sided nano-silver capacitive screen, comprising a double-sided nano-silver film 21, an OCA glue layer 22 and a glass cover plate 23, the double-sided nano-silver film includes a base material and a double-layer conductive layer, and the conductive layer material It is nano silver, and the base material is PMMA.

[0047] A method for preparing an ultra-thin double-sided nano-silver capacitive screen. On a double-sided nano-silver film, an OCA adhesive layer is laminated roll-to-roll and covered with a glass cover. The double-sided nano-silver film is prepared by roll-to-roll laser etching. become.

[0048] Further, the preparation method of described two-sided nano-silver film comprises:

[0049] (1) adopting wet coating conductive material on the base film to prepare the double-sided nano-silver conductive film;

[0050] (2) laser etching out conductive circuit patterns on the double-sided nano-silver conductive film;

[0051] (3) making double-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com