Method for etching magnetic tunnel junction of MRAM (Magnetic Random Access Memory)

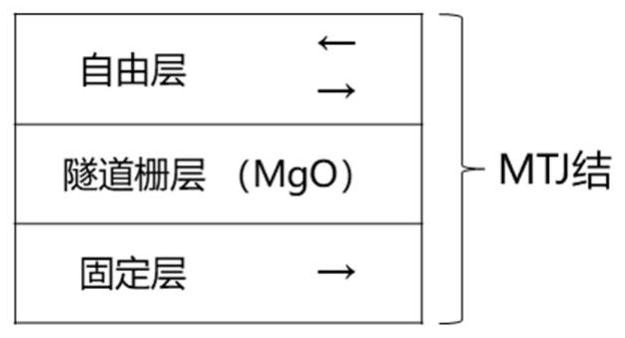

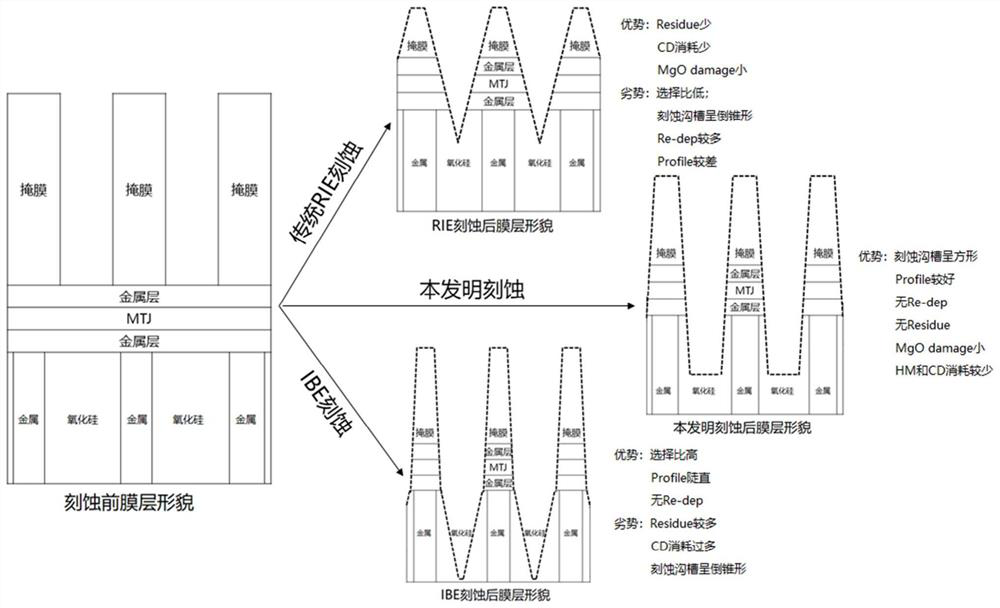

A technology of magnetic tunnel junction and etching amount, which is applied in the fields of magnetic field-controlled resistors, electromagnetic device manufacturing/processing, semiconductor devices, etc., which can solve problems such as difficulty in meeting etching requirements, achieve improved etching effects, and improve TMR and service life, the effect of eliminating bottom deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

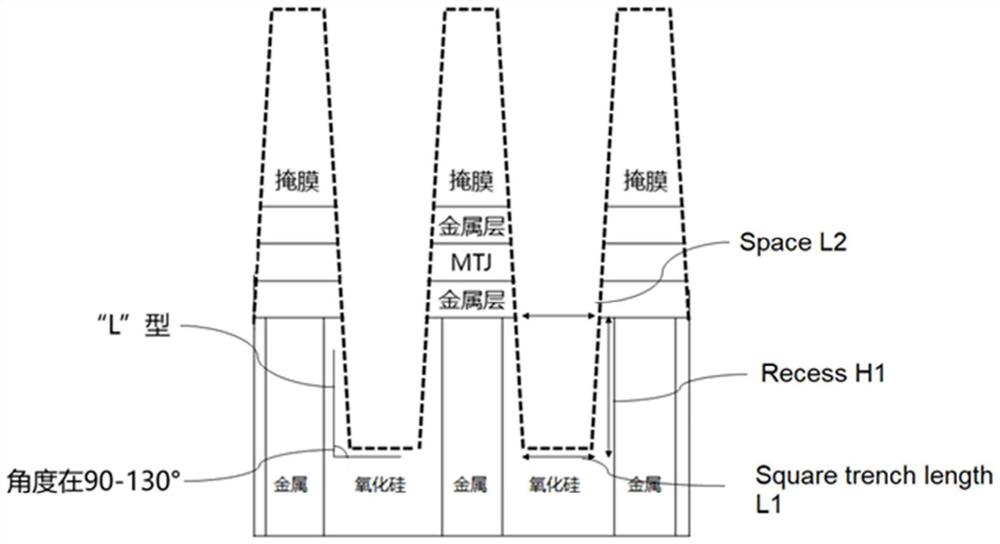

[0075] Step 1, the main engraving step is carried out using reactive ion etching: will be as follows Figure 2 The magnetic tunnel junction sample shown is passed into the RIE chamber for main engraving, and the main stepping energy is 500W source power, bias power is 600W, cavity pressure is 20mTorr, and etch gas is Kr.

[0076] Reaction ion etching stops at the remaining 10nm of the lowest metal layer to a depth of 40nm of the bottom medium layer, in the present embodiment, a etching is preferably stopped at the remaining 5nm of the lowest metal layer, the etching amount is preferably t1 is preferably 35nm.

[0077] Step 2, the cleaning step is performed using a combination of reactive ion etching RIE + ion beam etching IBE

[0078] Step 21, reactive ion etching RIE: Through the vacuum chamber, the magnetic tunnel completed by the main engraving step of step 1 is knotted into a sample, and the secondary reaction ion etching is carried out. The parameters of the secondary reaction i...

Embodiment 2

[0083] Step 1, the main engraving step is carried out using reactive ion etching: will be as follows Figure 4The magnetic tunnel junction sample shown is fed into the reaction ion chamber, the reaction ion etching ion source power is 600W, the bias voltage is 600V, the cavity pressure is 10mT, and the argon flow rate is 150 sccm. Among them, the magnetic tunnel junction sample to be etched includes the mask layer, cap layer, MTJ junction, bottom electrode layer and bottom medium layer from top to bottom. Reactive ion etching stops at 3 nm consumed at the bottom electrode layer. At this time, the amount of reaction ion etching is 20 nm.

[0084] Step 2, the use of reactive ion etching for cleaning step: the secondary etching process conditions are preferably: reactive ion pulse Pulse selection 5%, reaction ion source power Source 300W, bias voltage at 600V, cavity pressure 1.5mT, argon flow rate of 200sccm, etching 30nm to the seed layer, that is, the reaction ion etching amount t2...

Embodiment 3

[0089] Step 1, the main step is carried out by using ion beam etching: the magnetic tunnel junction sample is passed into the ion beam etching chamber, and the direction angle of the ion beam is selected as 25°, the energy is 600V, and the shielding gas is selected as argon gas etching. Among them, the magnetic tunnel junction sample includes the mask layer, cap layer, MTJ junction, bottom electrode metal layer and bottom medium layer from top to bottom. The bottom medium layer is nested at a medium distance with an electrode under metal equal to the number of masks in the mask layer, and the electrode under metal corresponds to the position of the mask. The ion beam etching stops at the remaining 5 nm of the lowest metal layer, that is, the ion beam etching amount t1 is 35 nm.

[0090] Step 2, the cleaning step is carried out by reactive ion etching: through the vacuum chamber, the magnetic tunnel junction sample from step 1 to complete the ion beam etching chamber is transferred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com