Hybrid material hole sealing agent for improving corrosion resistance of plasma spraying coating in acid environment

A hybrid material, ion spraying technology, used in coatings, metal material coating processes, melt spraying and other directions, can solve the problems of reducing coating porosity, poor toughness of inorganic sealing agents, high electrochemical corrosion voltage, etc. , to achieve the effect of good sealing effect and strong acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Improving the hybrid material sealing agent of plasma spray coating corrosion resistance under acidic environment

[0021] A hybrid material sealing agent for improving the corrosion resistance of plasma sprayed coatings in an acidic environment, characterized in that the hybrid material sealing agent is composed of analytically pure tetraethyl orthosilicate, absolute ethanol, N,N- Dimethylformamide, chemically pure γ-methacryloxypropyl trimethoxysilane, 25vol.% nitric acid, 25vol.% ammonia water, distilled water reagent, the proportion by volume is: ethyl orthosilicate : absolute ethanol: distilled water: γ-methacryloxypropyltrimethoxysilane=4: 3: 1: 6, N,N-dimethylformamide volume is tetraethyl orthosilicate, anhydrous The amount of ethanol, distilled water and γ-methacryloxypropyltrimethoxysilane reagent is 30% of the total volume. Among them, 25vol.% nitric acid was used to adjust the pH value in the process of hydrolysis and condensation of ethyl tet...

Embodiment 2

[0027] Embodiment 2: Improving the hybrid material sealing agent of plasma spray coating corrosion resistance under acidic environment

[0028] A hybrid material sealing agent for improving the corrosion resistance of plasma sprayed coatings in an acidic environment, characterized in that the hybrid material sealing agent is composed of analytically pure tetraethyl orthosilicate, absolute ethanol, N,N- Dimethylformamide, chemically pure γ-methacryloxypropyl trimethoxysilane, 25vol.% nitric acid, 25vol.% ammonia water, distilled water reagent, the proportion by volume is: ethyl orthosilicate : absolute ethanol: distilled water: γ-methacryloxypropyltrimethoxysilane=4: 3: 1: 4, N,N-dimethylformamide volume is tetraethyl orthosilicate, anhydrous The amount of ethanol, distilled water and γ-methacryloxypropyltrimethoxysilane reagent is 20% of the total volume. Among them, 25vol.% nitric acid was used to adjust the pH value in the process of hydrolysis and condensation of ethyl tet...

Embodiment 3

[0034]Embodiment 3: the sealing treatment of plasma spray coating

[0035] After the hybrid material sealing agent prepared in Example 1 was left to age for 1 hour, sealing treatment was performed. Put the plasma sprayed sample into the sealing agent, soak for 20-30min, take it out and dry it in the air, then bake it in the oven at 100°C, the sealing agent is completely dry, take the sample out of the oven, and dry it in the air Cool to room temperature, use 1200# sandpaper to grind the resin on the surface of the coating, and then soak it in the prepared hybrid sealing agent, the steps are as above, and finally grind off the sealed coating with 1200# sandpaper Excess resin on the coating surface, set aside;

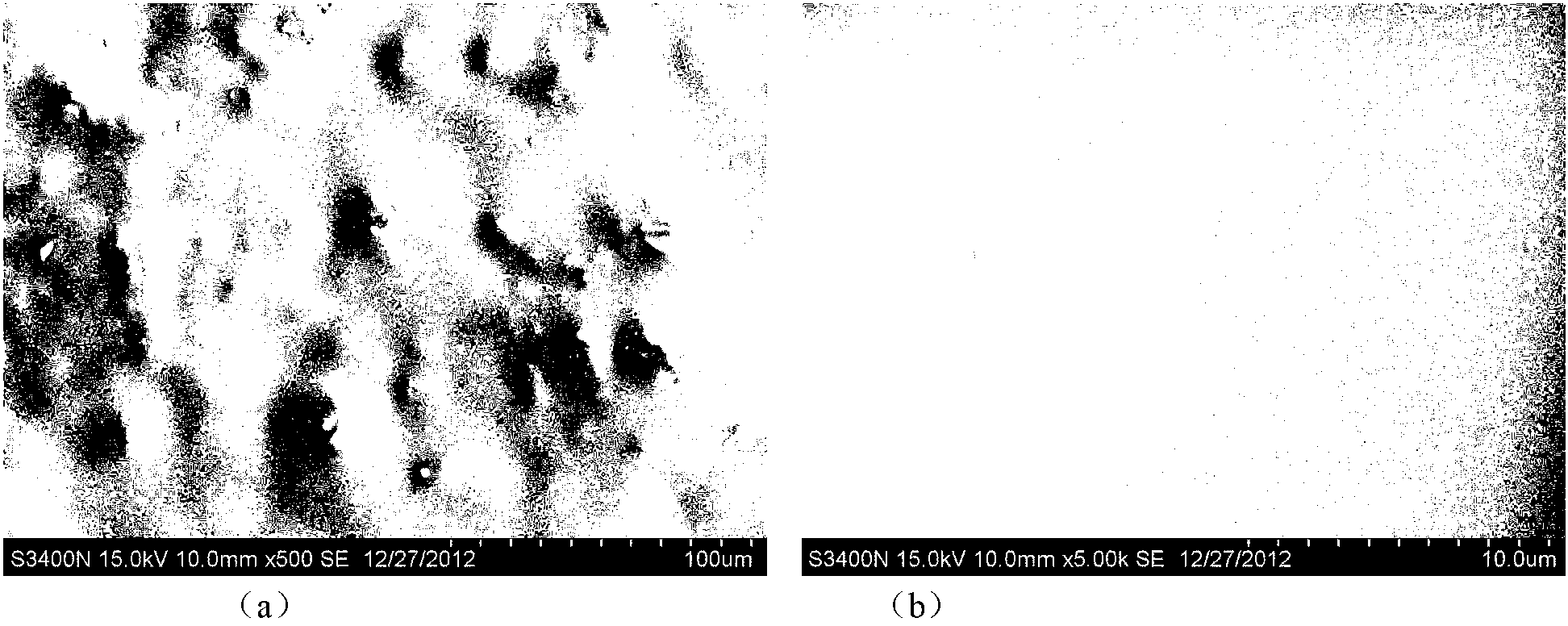

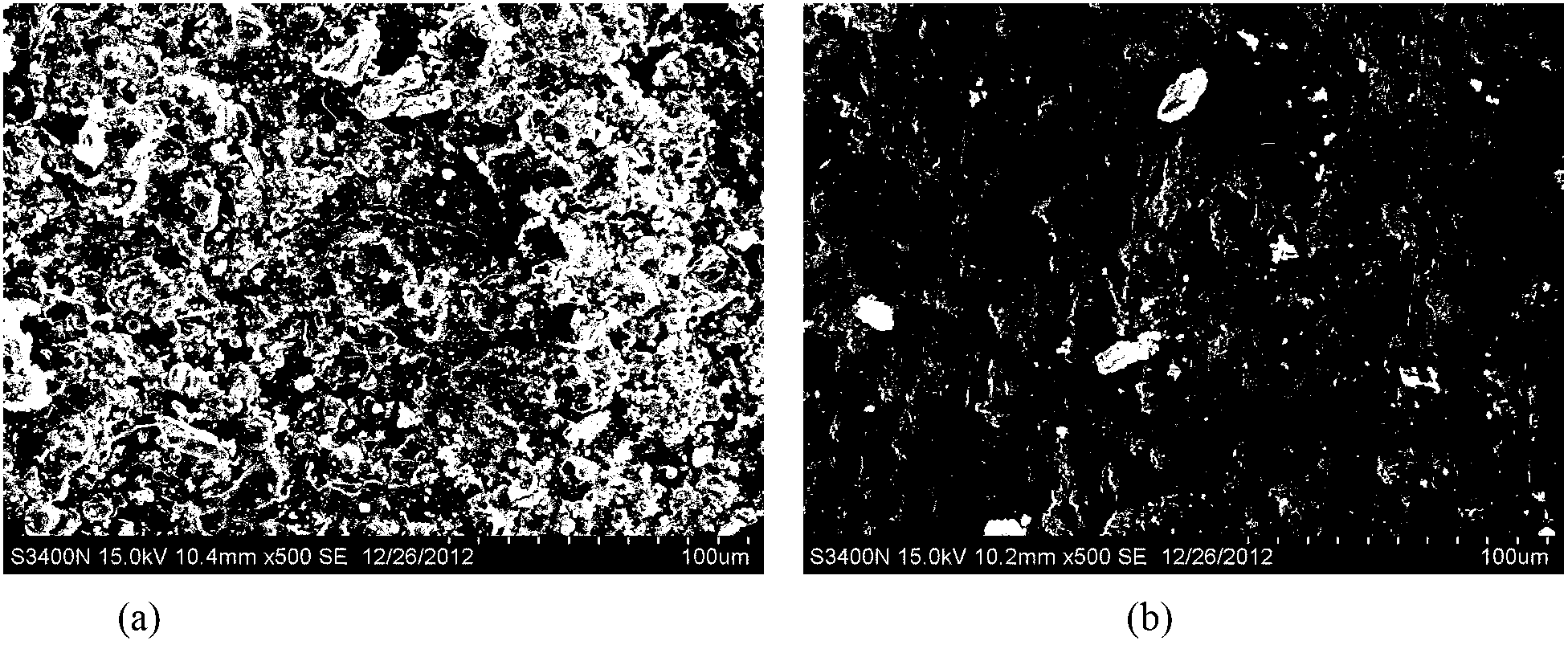

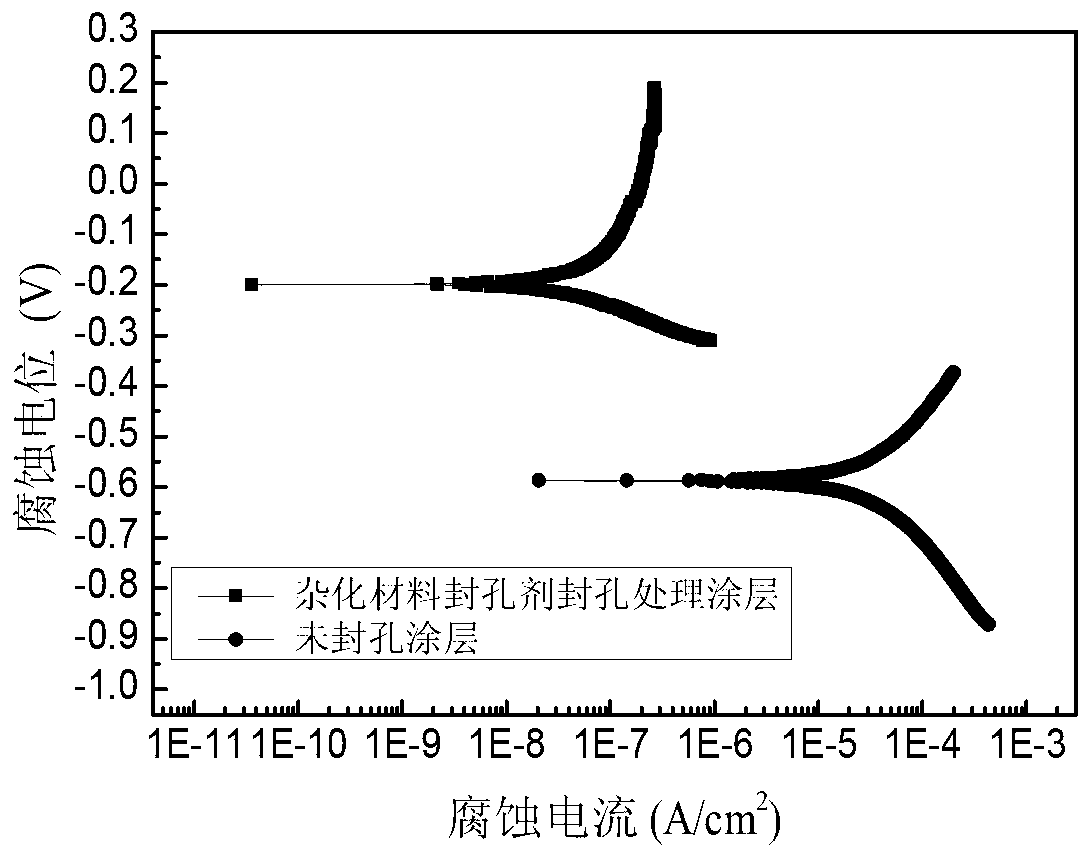

[0036] The surface morphology of the plasma sprayed coating after the sealing treatment of embodiment 3 is as follows figure 1 shown. It can be seen that after sealing the plasma sprayed coating with the prepared sealing agent, the sealing agent forms a uniform and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com