Silane coupling agent hydrolysate, as well as preparation method and application thereof

A technology of silane coupling agent and hydrolyzate, which is applied in the field of silane coupling agent hydrolyzate and its preparation, can solve the problems of less anticorrosion research on metal iron, achieve good anticorrosion effect, stable performance, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

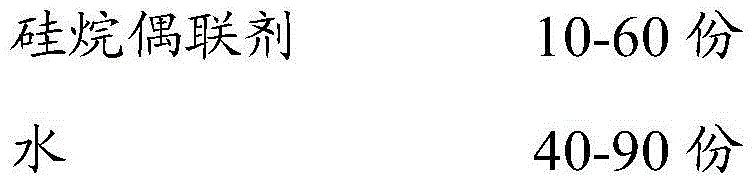

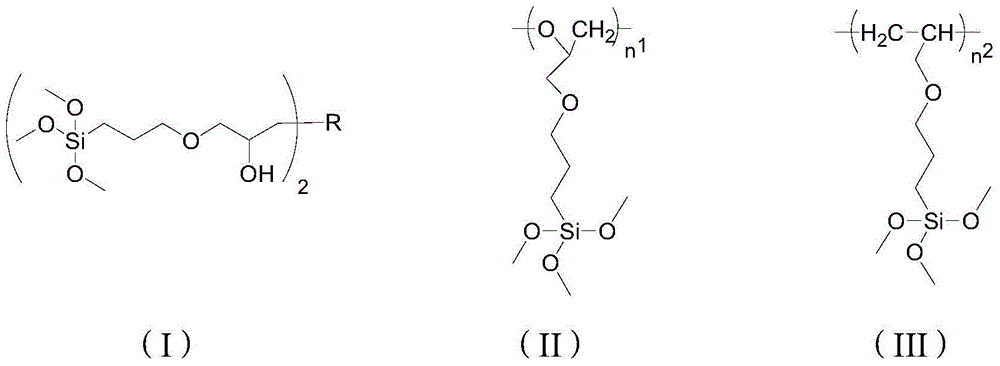

[0062] A kind of silane coupling agent hydrolyzate of the present embodiment comprises the raw material of following weight portion:

[0063] 40 parts of silane coupling agent

[0064] 40 parts of water

[0065] 20 parts of ethanol,

[0066] Adjust the pH of the hydrolyzate of the silane coupling agent to 4.0, and the silane coupling agent is BTSE.

[0067] The preparation method of above-mentioned silane coupling agent hydrolyzate comprises the steps:

[0068] Mix the silane coupling agent, alcohol and water in parts by weight, adjust the pH value to 4.0, stir at 30° C. for 10 h until the system is clear and transparent, and obtain the hydrolyzed solution of the silane coupling agent.

[0069]The silane coupling agent hydrolyzate can be stored at room temperature for 50 hours without gelling; the polished tinplate sheet is immersed in it for 30 seconds, dried, and dried at 120°C for 30 minutes, and it can withstand the salt spray accelerated corrosion test for 48 hours.

Embodiment 2

[0071] A kind of silane coupling agent hydrolyzate of the present embodiment comprises the raw material of following weight portion:

[0072] 40 parts of silane coupling agent

[0073] 60 parts of water,

[0074] Adjust the pH of the hydrolyzate of the silane coupling agent to 5.0, and the silane coupling agent is KH-560.

[0075] The preparation method of above-mentioned silane coupling agent hydrolyzate comprises the steps:

[0076] Mix the silane coupling agent and water in parts by weight, adjust the pH value to 5.0, stir at 30° C. for 20 h until the system is clear and transparent, and obtain the hydrolyzed solution of the silane coupling agent.

[0077] The silane coupling agent hydrolyzate can be stored at room temperature for 30 days without gelling; the polished tinplate sheet is immersed in it for 30 seconds, dried, and dried at 120°C for 30 minutes, and it can withstand the salt spray accelerated corrosion test for 20 hours.

Embodiment 3

[0079] A kind of silane coupling agent hydrolyzate of the present embodiment comprises the raw material of following weight portion:

[0080] 10 parts of silane coupling agent

[0081] 40 parts of water

[0082] 20 parts of ethanol,

[0083] Adjust the pH of the hydrolyzate of the silane coupling agent to 6.5, and the silane coupling agent is KH-550.

[0084] The preparation method of above-mentioned silane coupling agent hydrolyzate comprises the steps:

[0085] Mix the silane coupling agent, alcohol and water in parts by weight, adjust the pH value to 6.5, and the system is clear and transparent, thus obtaining the hydrolyzed solution of the silane coupling agent.

[0086] The hydrolyzate of the silane coupling agent can be stored at room temperature for 5 hours without gelling; the polished tinplate sheet is immersed in it for 30 seconds, dried, and dried at 180°C for 30 minutes, and it can withstand the salt spray accelerated corrosion test for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com