Valve sealing gasket sizing material and preparation method thereof

A valve sealing and gasketing technology, applied in the field of synthetic rubber, can solve the problems of uneven dispersion of processing aids, unfavorable occupational safety of workers, poor tearing and oil resistance, etc., to achieve good mechanical properties, improve comprehensive performance, and improve high resistance low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

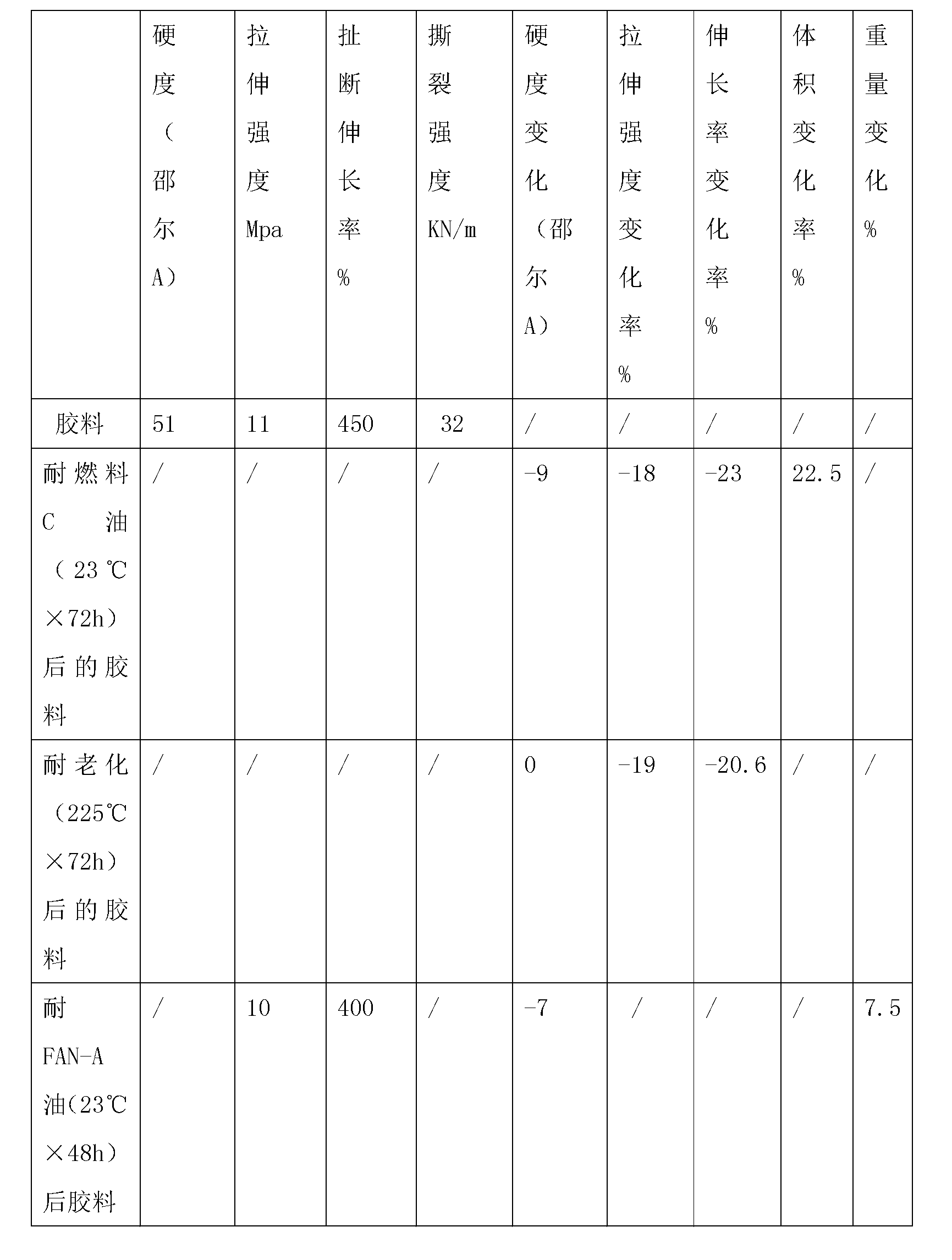

Examples

Embodiment Construction

[0020] A kind of preparation of automobile valve oil seal rubber,

[0021] Weigh 25kg of fluorosilicone rubber, 55kg of hydrogenated nitrile rubber, 20kg of chlorosulfonated polyethylene rubber TS-320 (Tosoh Japan), 2.5kg of γ-methacryloxypropyl trimethoxysilane, diphenylsilane Diol 1.5kg, modified tree ash 15kg, ferrocene 2.5kg, dicumyl peroxide DCP 0.5kg, high wear-resistant carbon black N330 25kg, precipitated white carbon black 22kg, light calcium carbonate 6kg, zinc oxide 3kg, calcium stearate 2kg, alumina 2kg, dolomite 7kg, modified iron tailings powder 14kg, accelerator MBTS0.2kg, sulfur 1.5kg, antioxidant RD 1.5kg, antioxidant MB1.5kg, 2-mercaptan Benzene imidazole 1.5kg, methyltrimethoxysilane 2kg, paraffin 2.5kg,

[0022] The preparation method comprises the following steps:

[0023] (1) Preparation method of modified tree ash:

[0024] Add triphenyl phosphate with 1-2% weight of tree ash to the tree ash and mix, soak with 15-20% hydrochloric acid for 1-2 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com