Surface grafting modified aramid fiber and preparation method thereof

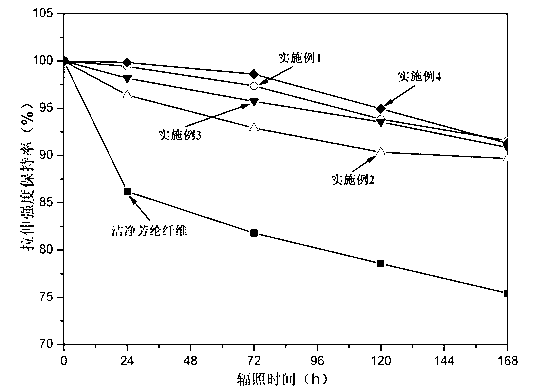

A surface graft modification, aramid fiber technology, applied in the direction of fiber treatment, fiber type, textile and papermaking, etc., can solve the problems of weak force, lifting, poor UV resistance of aramid fiber, etc., to improve the reaction Activity, improve UV resistance, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

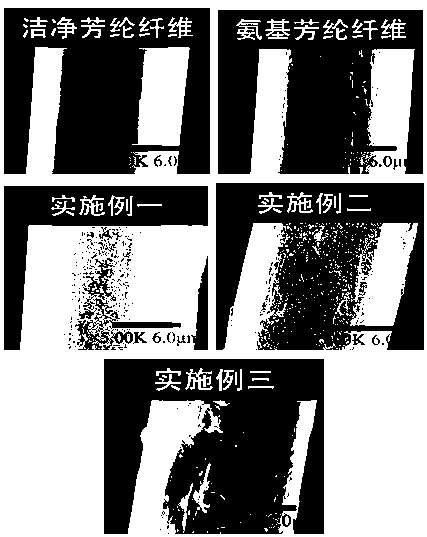

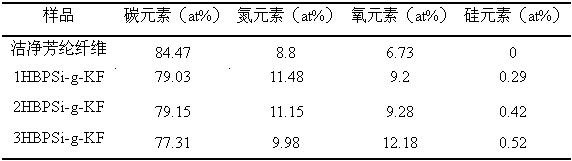

Embodiment 1

[0027] 1. Put 0.5g para-aramid fiber (Kevlar-49, diameter 14.62μm, density 1.44g / cm 3 , produced by DuPont, USA) was placed in 150mL acetone and heated to reflux for 3 hours. After the reflux is finished, the fiber is taken out and soaked in 150 mL of deionized water for 3 hours. Then the fibers were taken out and dried in vacuum at 80° C. for 12 hours to obtain clean aramid fibers.

[0028] 2. Pretreatment of aramid fiber

[0029] Mix 10mL of concentrated nitric acid, 200mL of acetic anhydride and 50mL of glacial acetic acid to obtain a mixed acid solution. Add 0.5 g of the clean aramid fiber obtained in step 1 into the mixed acid solution, and react at 10° C. for 6 h. After the reaction, the fiber is taken out, washed and dried to obtain the aramid fiber with nitro groups on the surface.

[0030]200mL of tetrahydrofuran and 200mL of deionized water were used to form a mixed solvent, and 1.5g of potassium dihydrogen phosphate and 0.2g of dipotassium hydrogen phosphate...

Embodiment 2

[0035] 1. Pretreatment of aramid fiber

[0036] Mix 20mL of concentrated nitric acid, 2mL of concentrated sulfuric acid and 200mL of acetic anhydride to obtain a mixed acid solution. Add 0.5 g of the clean aramid fiber prepared in Example 1 into the mixed acid solution, and react at 10° C. for 4 hours. After the reaction, the fiber is taken out, washed and dried to obtain the aramid fiber with nitro groups on the surface.

[0037] Mix 300ml of deionized water and 80mL of hydrogen peroxide to prepare a reducing medium. Add 0.5 g of aramid fibers with nitro groups on the surface to the reducing medium, then add 3.8 g of stannous chloride, stir and react at 60° C. for 12 hours, take out the fibers, wash with water, and dry to obtain amino aramid fibers. Measured-NH 2 The content is 3.87wt%.

[0038] 2. Put 0.5g of the aramid fibers with amino groups obtained in step 1 of this embodiment, 25g of γ-glycidyl etheroxypropyl trimethoxysilane and 0.015g of sodium hydroxide into a r...

Embodiment 3

[0042] 1. Pretreatment of aramid fiber

[0043] Mix 10 mL of concentrated nitric acid and 200 mL of acetic anhydride to prepare a mixed acid solution, add 0.5 g of the clean aramid fiber prepared in Example 1 into the mixed acid solution, and react at 10°C for 5 hours. After the reaction, the fiber is taken out, washed and dried to obtain the aramid fiber with nitro groups on the surface.

[0044] Add 2.4 g of potassium dihydrogen phosphate and 1.2 g of dipotassium hydrogen phosphate to 400 ml of tetrahydrofuran to prepare a reducing medium. Add 0.5 g of aramid fibers with nitro groups on the surface to the reducing medium, then add 2.8 g of sodium borohydride, stir and react at 30° C. for 24 hours, take out the fibers, wash them with water, and dry them to obtain amino aramid fibers. Measured-NH 2 The content is 4.63wt%.

[0045] 2. Put 0.5g of the aramid fibers with amino groups obtained in Step 1 of this embodiment, 120g of γ-glycidyl etheroxypropyl trimethoxysilane and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com