Colored anti-skid pavement paving material and paving method thereof

A kind of paving material and anti-skid technology, which is applied in the direction of roads, roads, and on-site coagulation pavement. It can solve the problems of poor combination, high cost, and inability to use mechanized construction, so as to solve the problem of low efficiency and ensure the quality of pavement. , to avoid the effect of uneven distribution of aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

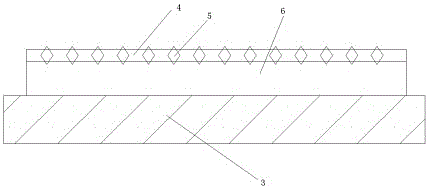

[0028] Such as figure 1 As shown, the self-luminous colored pavement includes a pavement base layer 3 from bottom to top, a one-time formed colored anti-slip pavement pavement layer 2, and one-time formed colored anti-slip pavement pavement substrate 2 contains distributed colored glass anti-slip aggregates.

[0029] A kind of colored non-slip pavement pavement pavement method in the present embodiment comprises the following steps:

[0030] S1: According to the thickness and BPN value required by the design of the colored anti-slip pavement, add the colored glass anti-slip aggregate to the base material, use an electric stirring tool to stir well, add it to the paving equipment, and use it up within one working day; BPN is the rebound deflection value of road signs.

[0031] S2: Pave the mixed base material in the ground pattern or logo template prepared according to the design requirements;

[0032] S3: Use paving equipment for construction, inject the aggregate base mater...

Embodiment 2

[0042] Such as figure 1 As shown, the self-luminous colored pavement includes a pavement base layer 3 from bottom to top, a one-time formed colored anti-slip pavement pavement layer 2, and one-time formed colored anti-slip pavement pavement substrate 2 contains distributed colored glass anti-slip aggregates.

[0043] A kind of colored non-slip pavement pavement pavement method in the present embodiment comprises the following steps:

[0044] S1: According to the thickness and BPN value required by the design of the colored anti-slip pavement, add the colored glass anti-slip aggregate to the base material, stir it with an electric stirring tool, add it to the paving equipment, and use it up within one working day;

[0045] The BPN is the rebound deflection value of road signs.

[0046] S2: Add 2-10% initiator at the same time, stir well together, and use it up within 15 minutes;

[0047]The initiator includes, but is not limited to, CX-50 type benzoyl peroxide.

[0048] S3: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com