Production process of modified asphalt waterproof coiled material

A waterproof membrane and production process technology, applied in the field of modified asphalt waterproof membrane production technology, can solve the problems of uneven surface of asphalt waterproof membrane, uneven distribution of isolation materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

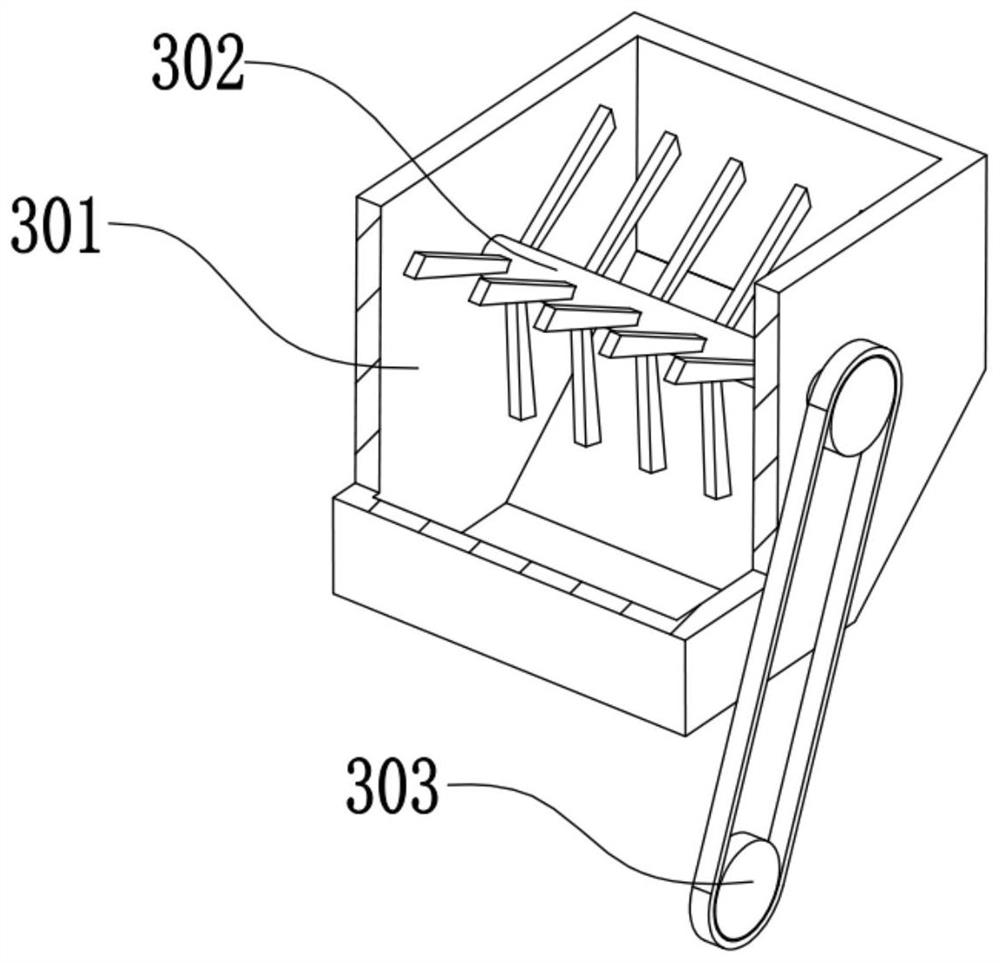

[0029] The spreading device includes a material box 301 and a rotating shaft 302 , and the rotating shaft 302 rotates in the material box 301 .

[0030] see figure 1 , as shown in the figure, an exemplary working process for agitating the powdery or flaky insulating material is:

[0031] After the powdery or flake insulating material is added into the material box 301, the rotating shaft 302 will be submerged therein, and the rotating shaft 302 slowly rotates in the powdery or flake insulating material to make the powdery or flake The isolation material is stirred up to prevent the powder or flake isolation materials from "bonding" or "sticking" to each other into a large piece of isolation material, thereby avoiding "bonding" or "sticking" into a large piece of isolation material being spread on on the asphalt on the surface of the base tire.

[0032] The rotating shaft 302 rotates around its own axis.

[0033] The material box 301 is provided with openings at both upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com