Method for modifying nano titanium dioxide sol by utilizing silane coupling agent

A technology of nano-titanium dioxide and silane coupling agent, which is applied in the field of modified inorganic nanoparticles, can solve the problems of difficult control process, high cost, complicated process, etc., and achieve the effect of expanding application range, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

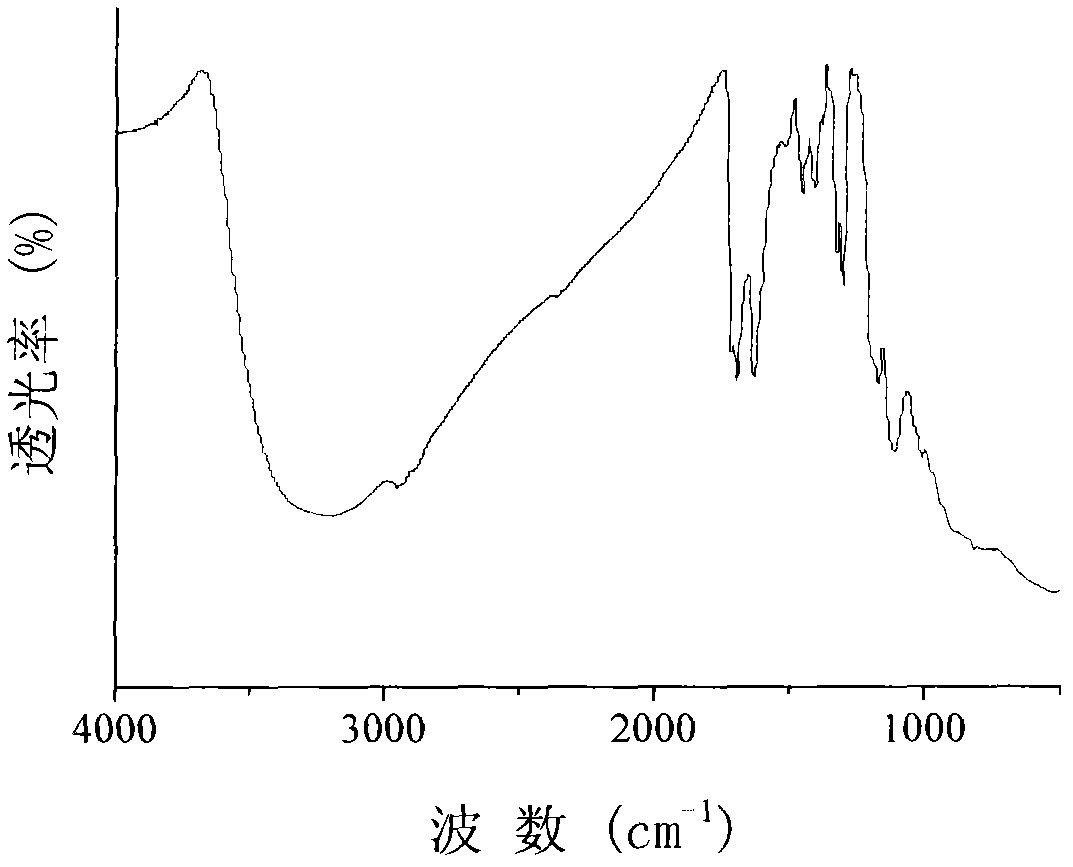

Method used

Image

Examples

Embodiment 1

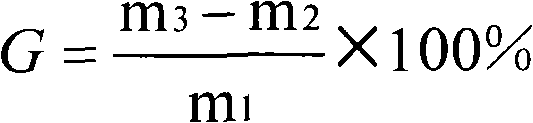

[0023] Add the mixed solution of 1.8g deionized water, 2.36g concentrated hydrochloric acid and 6.91g absolute ethanol dropwise to the mixed solution prepared by 17.02g butyl titanate and 6.91g absolute ethanol, control the dripping within 15min, and then Stir for 0.5h, then slowly add 0.31g of silane coupling agent KH-570, raise the temperature to 80°C and react for 1.5h, then end the reaction to obtain KH-570 modified nano-TiO 2 Sol. The relative grafting ratio and particle size of the prepared silane coupling agent-modified nano-titanium dioxide sol are shown in Table 1.

Embodiment 2

[0025] Add the mixture of 3.6g of deionized water, 1.18g of concentrated hydrochloric acid and 11.52g of absolute ethanol dropwise into the mixture of 17.02g of butyl titanate and 11.52g of absolute ethanol, control the dripping within 15min, and then Stir for 0.5h, then slowly add 1.24g of silane coupling agent KH-570 (A-171), raise the temperature to 80°C and react for 1.5h, then end the reaction to obtain KH-570 modified nano-TiO 2 Sol. The relative grafting ratio and particle size of the prepared silane coupling agent-modified nano-titanium dioxide sol are shown in Table 1.

Embodiment 3

[0027] Add the mixture of 1.8g of water, 2.36g of concentrated hydrochloric acid and 6.91g of absolute ethanol dropwise into the mixture of 17.02g of butyl titanate and 6.91g of absolute ethanol, control the dripping within 15min, and then stir for 0.5 h, then slowly added 2.07g of silane coupling agent KH-570 (A-151), stirred at room temperature for 6h, raised the temperature to 80°C for 1.5h, and ended the reaction to obtain KH-570 modified nano-TiO 2 Sol. The relative grafting ratio and particle size of the prepared silane coupling agent-modified nano-titanium dioxide sol are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com