Wood flour/polypropylene wood-plastic composite material using silane modified ammonium polyphosphate as fire retardant and preparation method thereof

A wood-plastic composite material, ammonium polyphosphate technology, applied in the field of wood powder/polypropylene wood-plastic composite material and its preparation, can solve the problems of poor flame retardant performance, poor heat resistance, low mechanical properties, etc. performance, improved compatibility, improved thermal degradation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: this embodiment is the wood powder / polypropylene wood-plastic composite material that uses silane-modified ammonium polyphosphate as a flame retardant, which consists of 50-70 parts of wood powder, 30-50 parts of polypropylene, 15-30 parts of silane-modified ammonium polyphosphate (M-APP), 3-6 parts of m-isopropenyl-α, α-dimethylbenzyl isocyanate grafted polypropylene (m-TMI-g-PP) The silane-modified ammonium polyphosphate is made of 80-100 parts of ammonium polyphosphate and 0.5-2 parts of γ-methacryloxypropyl trimethoxy made from silane.

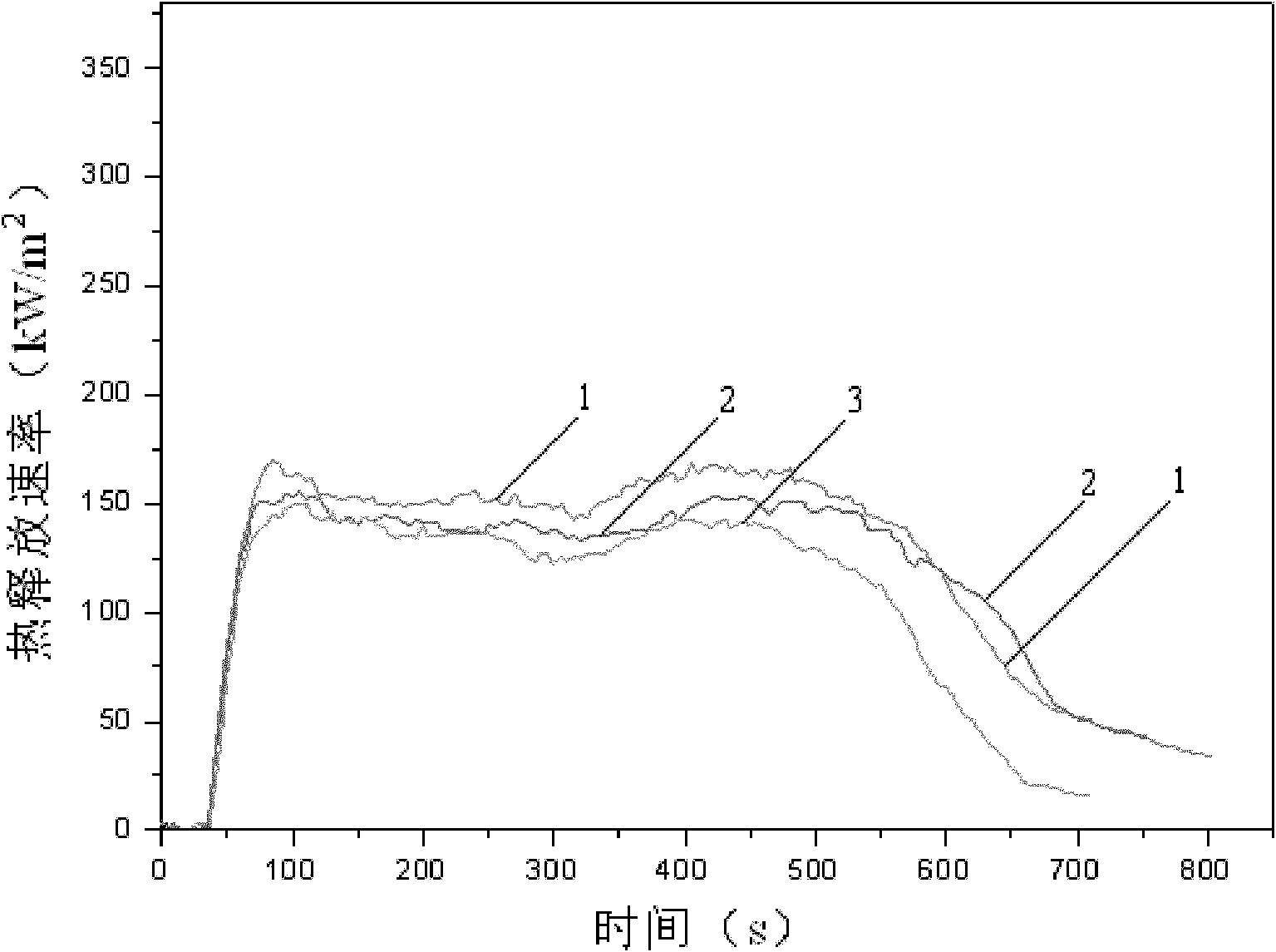

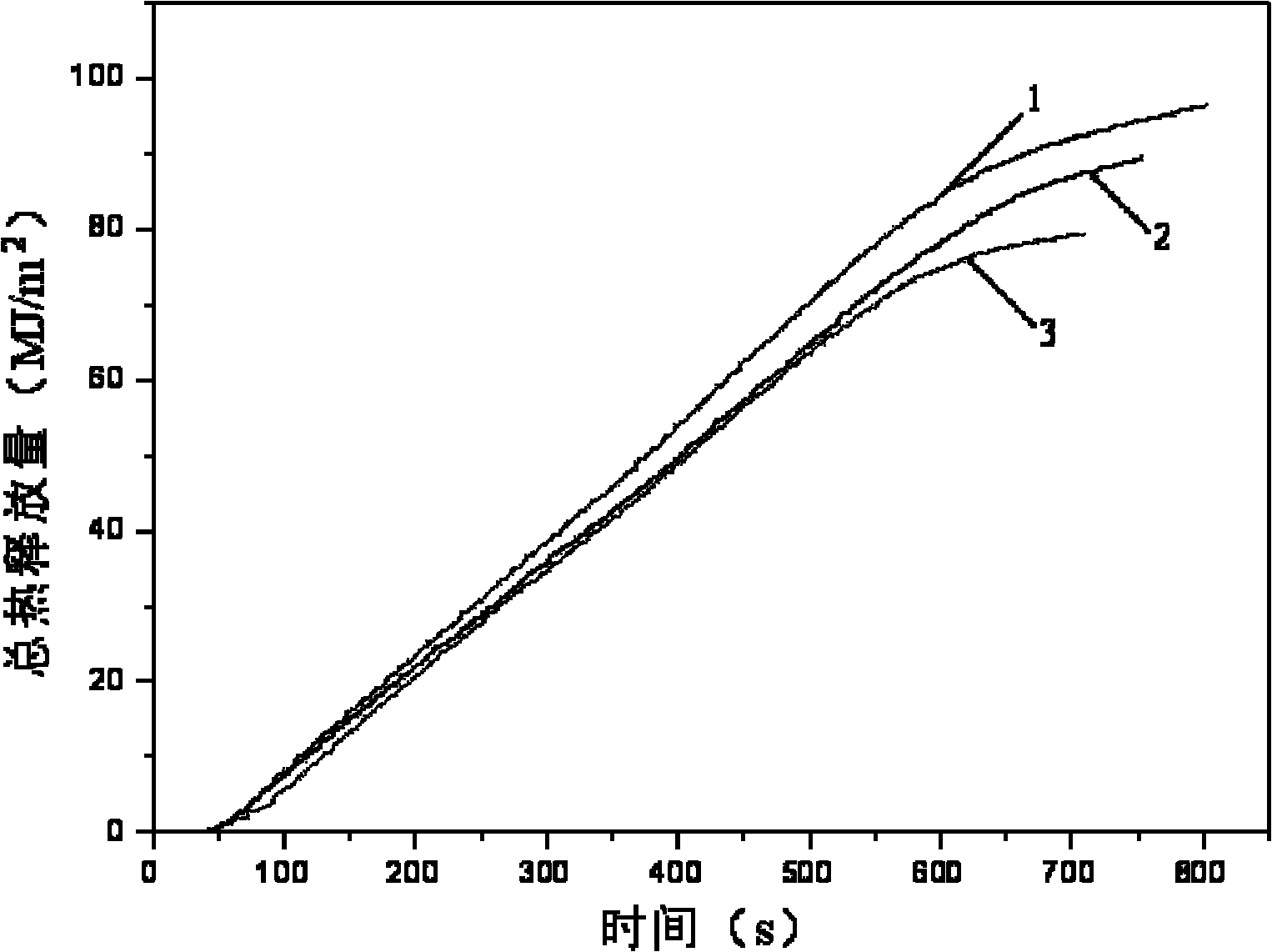

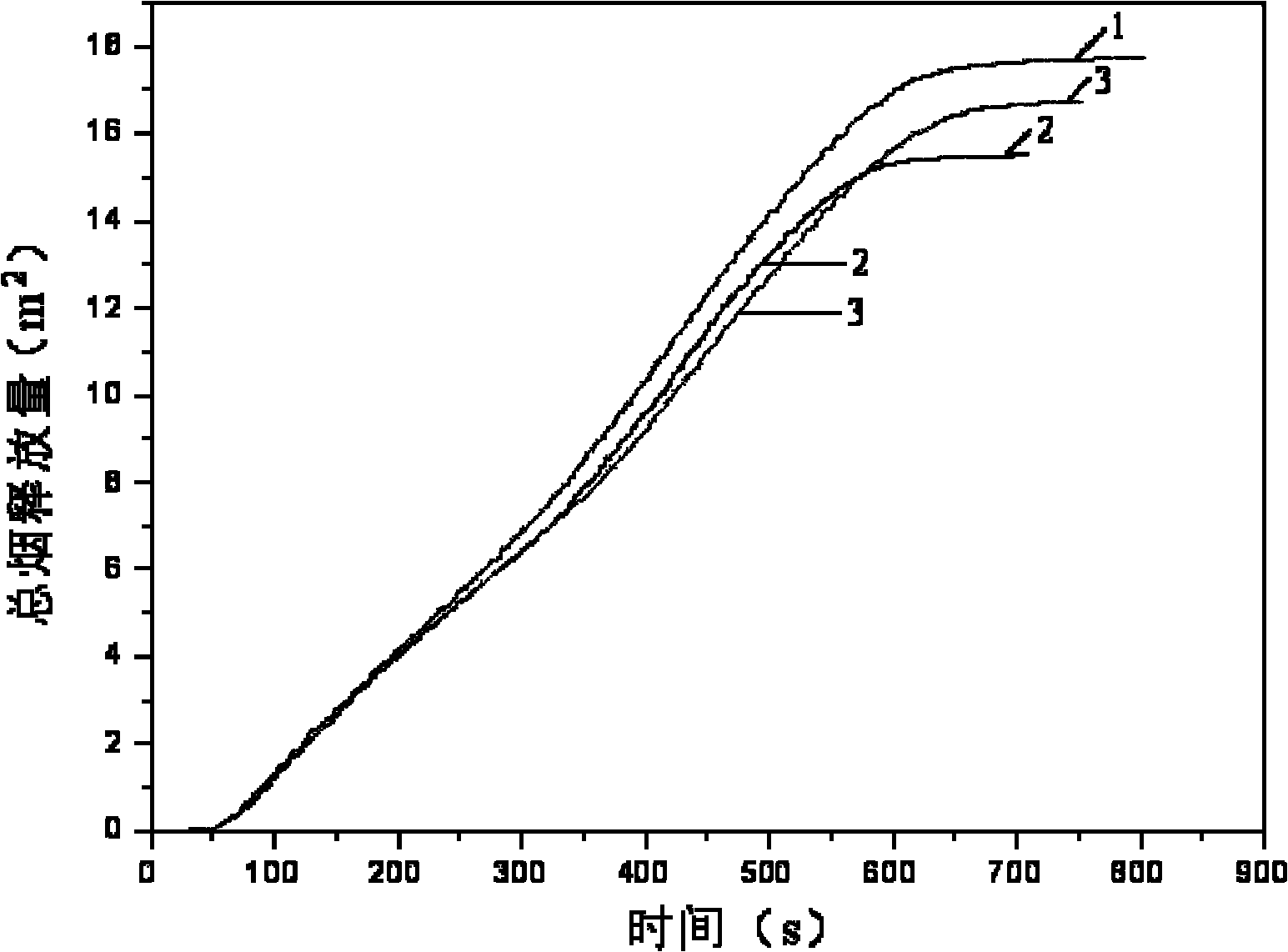

[0026] The wood powder / polypropylene wood-plastic composite material of this embodiment using silane-modified ammonium polyphosphate as a flame retardant has good mechanical properties, with a tensile strength of 24.93-28.04MPa, a bending strength of 61.98-65.68MPa, and an impact strength of 4.11~5.75kJ / m 2 ; Good heat resistance, the temperature at which the weight loss is 1% (T 1wt% ) is 102.3~108.3℃, t...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is by weight by 60 parts of wood flour, 40 parts of polypropylene, 20 parts of silane modified ammonium polyphosphate, 6 parts of m-isopropenyl-α, α - Made of dimethyl benzyl isocyanate grafted polypropylene coupling agent and 1 part antioxidant. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one is that by weight, 60 parts of wood flour, 40 parts of polypropylene, 25 parts of silane modified ammonium polyphosphate, 6 parts of m-isopropenyl-α, α - Made of dimethyl benzyl isocyanate grafted polypropylene coupling agent and 1 part antioxidant. Other parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com