High-performance nano carbon cooling composite material

A composite material and nano-carbon technology, which is applied in the direction of film/flaky adhesives, coatings, adhesives, etc., can solve the problems of poor thermal conductivity or heat dissipation of conductive materials, so as to improve adhesion, improve processability and Flexibility, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail through the following examples. These examples are preferred embodiments of the present invention and are only used to illustrate the present invention and do not limit the scope of the present invention.

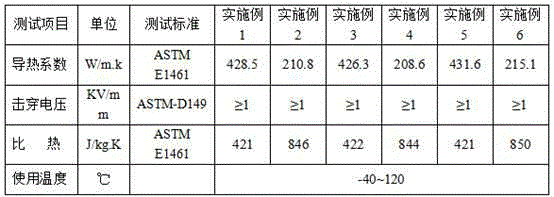

[0018] Embodiments 1 to 6 adopt the formula (composed by parts by weight) as shown in Table 1 to prepare the high-performance nano-carbon heat dissipation composite material of the present invention, wherein the nano-carbon is carbon nanotubes, carbon nanofibers, and nano-carbon spheres according to the mass It is obtained by mixing at a ratio of 1:3:4; the processing aids are: 3 parts of propyltrimethoxysilane, 7 parts of γ-methacryloxypropyltrimethoxysilane, and 1 part of polyethylene glycol.

[0019] During preparation, premix γ-methacryloxypropyltrimethoxysilane and nano-carbon for 5-15 minutes by spraying, then dry for 5 minutes under a vacuum of 0.04MPa, and then mix organic resin, propyltrimethoxysilane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com