Preparation method of molecularly imprinted polymer on nano-silica gel surfaces of sulfonylurea herbicides

A nano-silica gel and molecular imprinting technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as unsatisfactory polymer affinity efficiency and difficult removal, achieve efficient and rapid separation and enrichment, improve efficiency, Effects that are easy to chemically modify and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

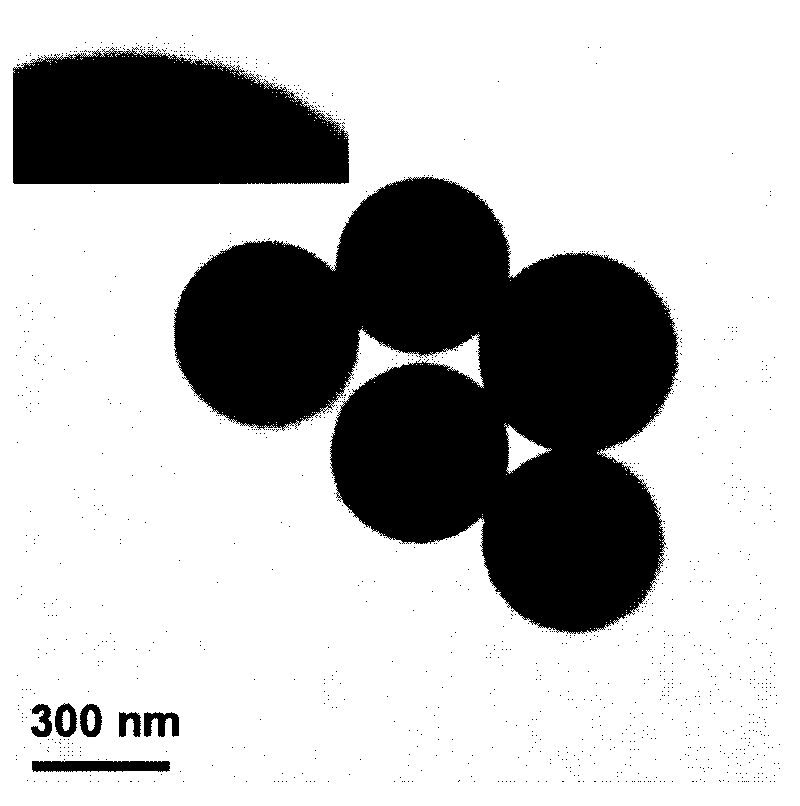

[0031] Embodiment 1. Preparation of SiO 2 small ball

[0032] Mix 50mL of absolute ethanol and 9mL of concentrated ammonia water to obtain solution A, and stir magnetically at high speed; then mix 30mL of absolute ethanol and 5mL of TEOS to obtain solution B; In the magnetically stirred solution A, react for 24 hours after the titration is completed; repeatedly ultrasonically wash with absolute ethanol until neutral, centrifuge, and vacuum-dry at 60°C until constant weight.

Embodiment 2

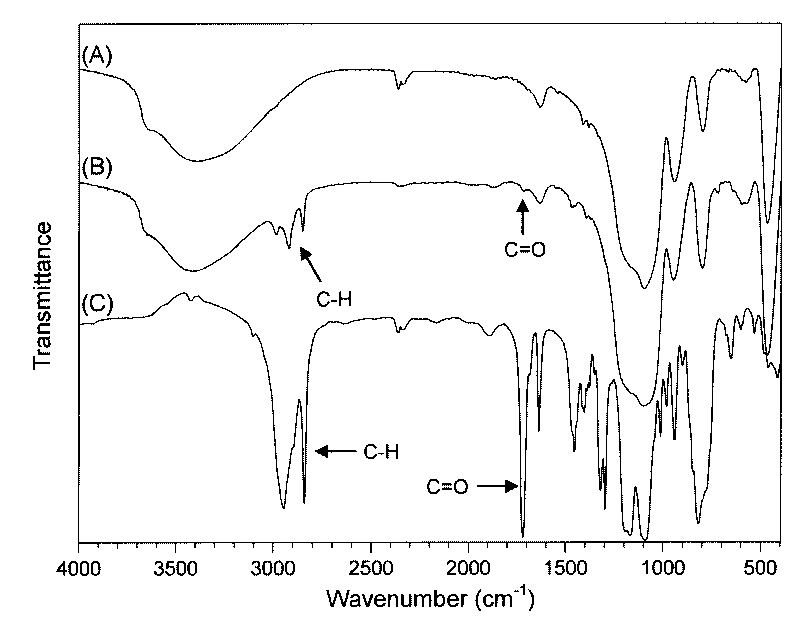

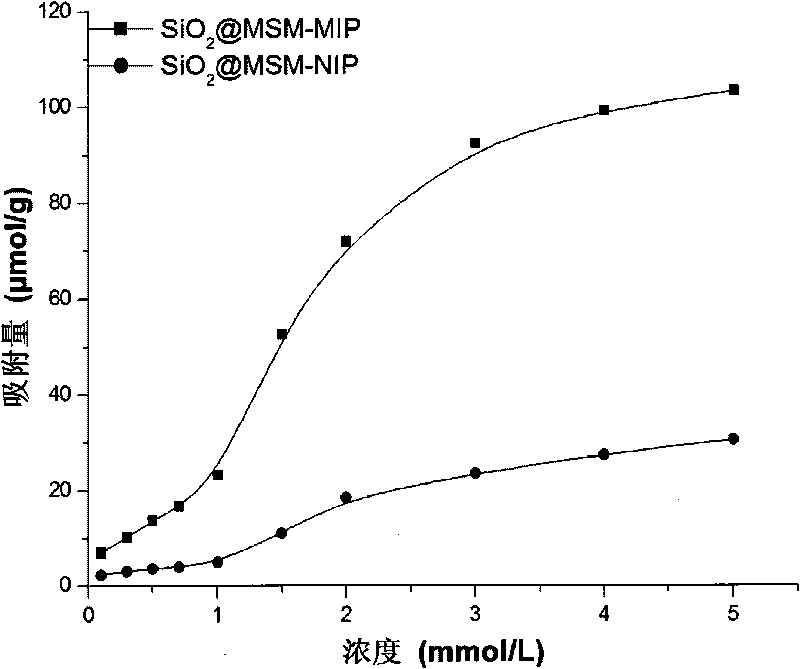

[0033] Example 2. Preparation of molecularly imprinted polymer SiO on the surface of metsulfuron-methyl silica gel 2 @MSM-MIP 1

[0034] (1) Add 0.2g SiO 2 Ultrasonic disperse the pellets in 40mL toluene solution, add 2mL γ-MPTS, pass N 2 Deoxygenation, magnetic stirring at 300rpm, reaction at 100°C for 12h, repeated ultrasonic washing with methanol, centrifugation to remove unreacted γ-MPTS, vacuum drying at 60°C to constant weight;

[0035] (2) Add 0.625mmol of MSM and 2.5mmol of MAA into 25mL of acetonitrile, mix well, shake well, and let stand for 4h to prepare a pre-assembly solution;

[0036] (3) 0.1g modified SiO 2 Ultrasonically disperse the beads in 25mL acetonitrile, add 5mmol EGDMA, 0.125mmol AIBN and the pre-assembly solution prepared in step (2), ultrasonicate for 5min in an ice bath, and pass N under magnetic stirring 2 Deoxygenation, temperature controlled heating to initiate polymerization, the heating program is as follows: react at 50°C for 6 hours, heat ...

Embodiment 3

[0040] Example 3. Preparation of molecularly imprinted polymer SiO on the surface of metsulfuron-methyl silica gel 2 @MSM - MIP 2

[0041] (1) Add 0.2g SiO 2 Ultrasonic disperse the pellets in 40mL toluene solution, add 2mL γ-MPTS, pass N 2 Deoxygenation, magnetic stirring at 300 rpm, reaction at 120°C for 12 hours, repeated ultrasonic washing with methanol, centrifugation to remove unreacted γ-MPTS, vacuum drying at 60°C to constant weight;

[0042] (2) Add 0.625mmol of MSM and 2.5mmol of MAA into 25mL of acetonitrile, mix well, shake well, and let stand for 4h to prepare a pre-assembly solution;

[0043] (3) 0.1g modified SiO 2 Ultrasonically disperse the beads in 25mL acetonitrile, add 5mmol EGDMA, 0.125mmol AIBN and the pre-assembly solution prepared in step (2), ultrasonicate for 5min in an ice bath, and pass N under magnetic stirring 2 Deoxygenation, temperature controlled heating to initiate polymerization, the heating program is as follows: react at 50°C for 6 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com