Polymer modified asphalt waterproof roll and production method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt layered products, chemical instruments and methods, and synthetic resin layered products. Poor properties and other problems, to achieve the effect of improving the interface bonding strength, enhancing the interface bonding force, and enhancing the cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

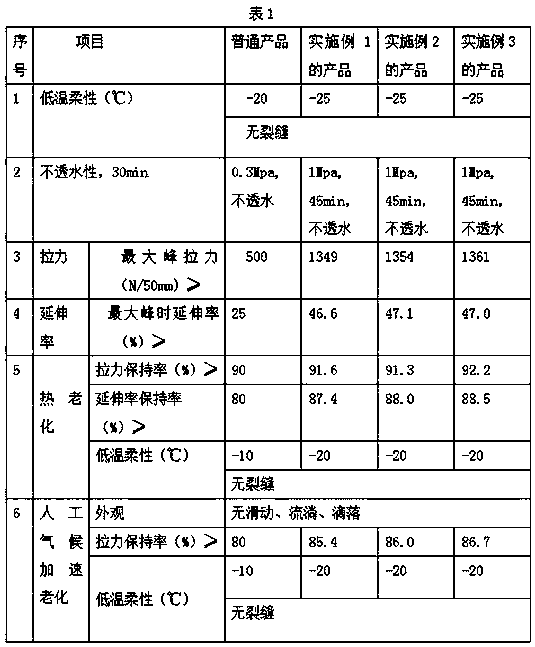

Embodiment 1

[0029] A polymer modified asphalt waterproofing membrane, the waterproofing membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper polymer modified asphalt layer, the base layer, the lower polymer modified asphalt layer and the lower surface isolation layer; the upper surface isolation layer and the lower surface isolation layer are PE films; the base layer is glass fiber mat;

[0030] The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 70 parts of 90# petroleum asphalt; 20 parts of machine oil; 18 parts of polymer modifier SBS thermoplastic rubber elastomer; 2 parts of γ-methacryloxypropyl trimethoxysilane; 1 part of softener dibutyl maleate; 8 parts of phenolized lignin; acetyl citric acid 1 part of trihexyl ester; 4 parts of viscosifier liquid coumarone; 1 part of sodium carboxymethy...

Embodiment 2

[0040] A polymer modified asphalt waterproofing membrane, the waterproofing membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper polymer modified asphalt layer, the base layer, the lower polymer modified asphalt Layer and lower surface isolation layer; upper surface isolation layer and lower surface isolation layer are PET film; base layer is glass fiber reinforced polyester felt;

[0041] The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 76 parts of 90# petroleum asphalt; 22 parts of machine oil; 20 parts of polymer modifier; 2.5 parts of γ-methacryloxypropyl trimethoxysilane; 1.5 parts of softener dibutyl maleate; 9 parts of phenolized lignin; 2 parts of acetyl trihexyl citrate ; 5 parts of viscosifier liquid coumarone; 2 parts of sodium carboxymethyl cellulose; 19 parts of modifi...

Embodiment 3

[0051] A polymer modified asphalt waterproofing membrane, the waterproofing membrane is a five-layer structure, from top to bottom: the upper surface isolation layer, the upper polymer modified asphalt layer, the base layer, the lower polymer modified asphalt layer and the lower surface isolation layer; the upper surface isolation layer and the lower surface isolation layer are PVC films; the base layer is glass fiber mat;

[0052] The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of modified asphalt, and the modified asphalt is made of the following raw materials in parts by weight: 80 parts of 90# petroleum asphalt; 25 parts of machine oil; 22 parts of polymer modifier; 3 parts of γ-methacryloxypropyltrimethoxysilane; 2 parts of softener dibutyl maleate; 10 parts of phenolized lignin; 3 parts of acetyl trihexyl citrate 6 parts of viscosifier liquid coumarone; 3 parts of sodium carboxymethyl cellulose; 15 parts of modified nano-cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com