UV curing luminous plate and its preparing process

A technology of light-emitting panels and light-emitting layers, used in chemical instruments and methods, light-emitting materials, instruments, etc., can solve the problems of complex processes, environmental pollution by solvents, energy consumption, etc., and achieve high luminous brightness, no environmental pollution, and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with example the present invention will be further described.

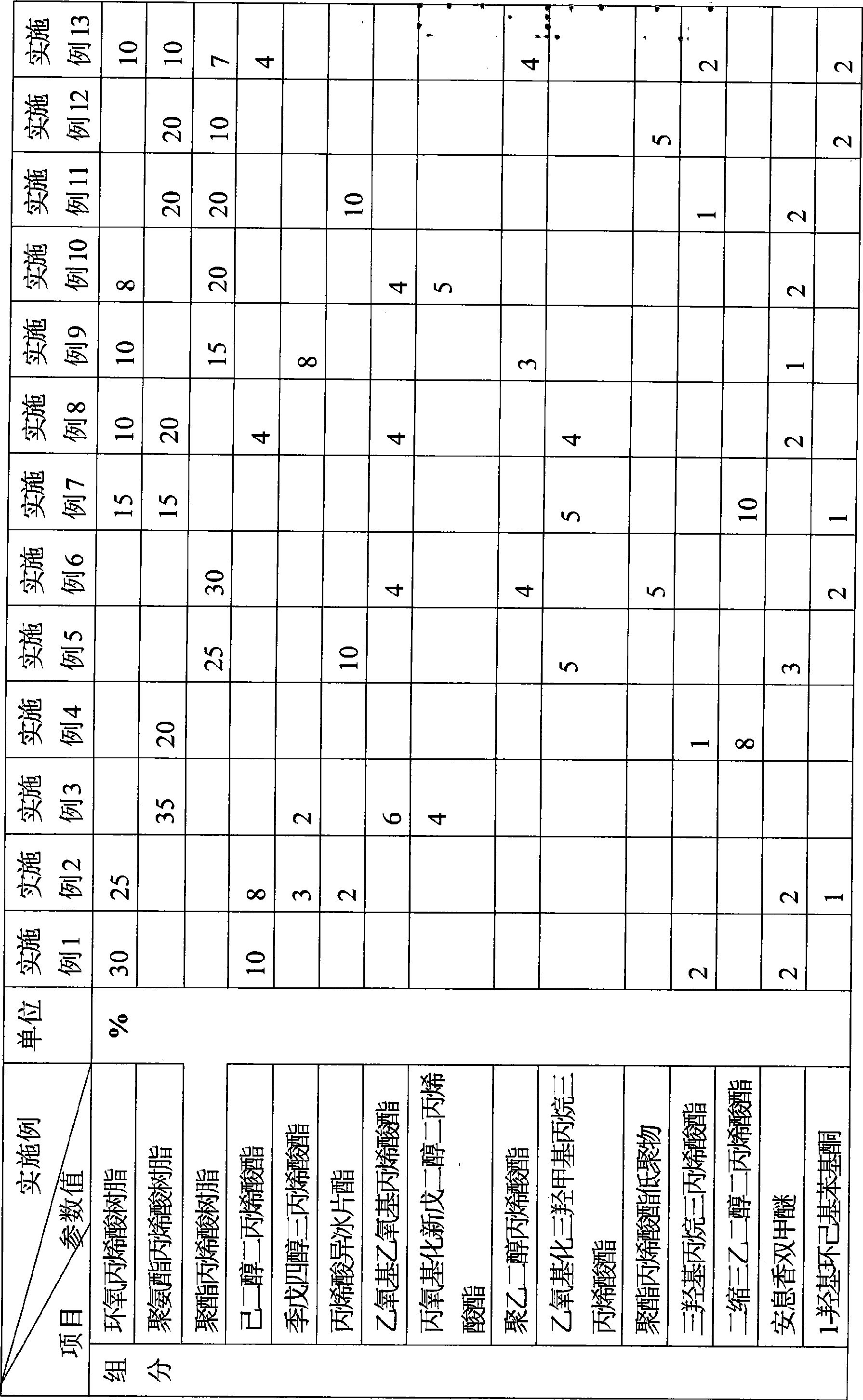

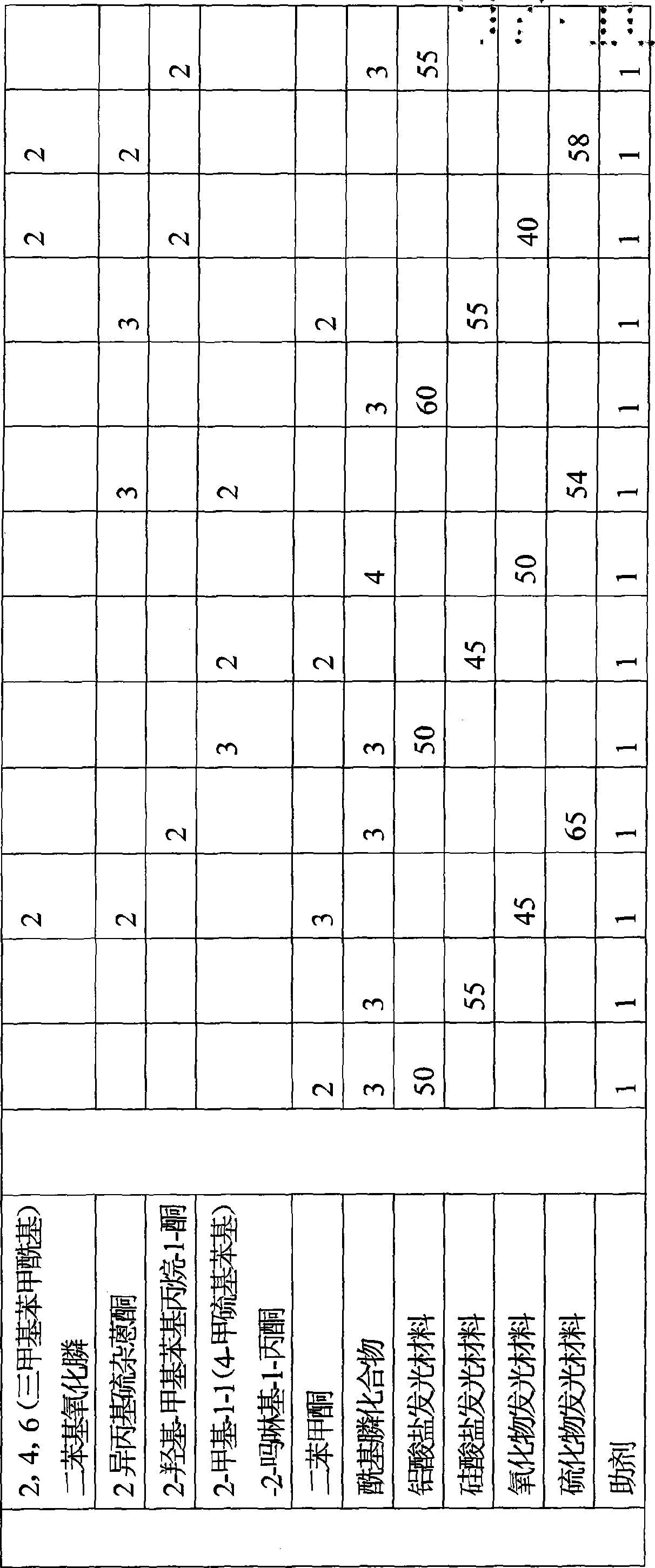

[0022] Various implementation examples and the contents of each component are listed in Table 1. The above example is the formulation of the luminescent layer. Weigh the raw materials according to the formula, add other materials except the luminescent material into the high-speed disperser, disperse evenly at high speed, and then add the luminescent material and disperse evenly at high speed to obtain the luminescent material.

[0023] There are three methods for making luminescent panels. The first is to apply luminescent paint directly on white or light-colored plates such as PVC whiteboards to form a luminescent layer with a thickness of 0.02-5.0mm and a wavelength of 200- 600nm, 5.6-8KW ultraviolet light source irradiation, speed 4.0-10.0m / min can get a uniform luminous panel. The second method is to directly use white or light-colored film as the reflective layer, apply luminesce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com