Transparent foam sole formulation and method of using formulation to make sole

A technology of formula and plastic granules, which is applied in the direction of shoe soles, applications, footwear, etc., can solve the problem of monotonous luminous mode of PU resin luminous powder or PU resin fluorescent ink layer, the influence of physical parameters on sole elasticity, yellowing resistance, compression deformation, Problems such as PU resin luminous powder or PU resin fluorescent ink layer falling off, to improve the effect of yellowing resistance, improve mechanical properties and physical properties, and achieve the effect of small mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples.

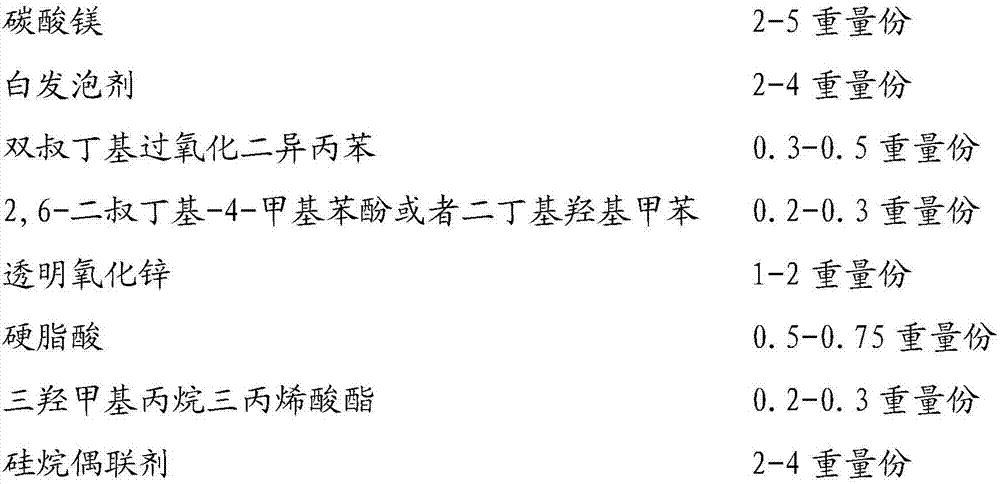

[0032] A formula for light-transmitting foamed shoe soles, consisting of plastic granules and ingredients, calculated on the basis of 100 parts by weight of plastic granules, and the ingredients are correspondingly composed of the following raw materials by weight:

[0033]

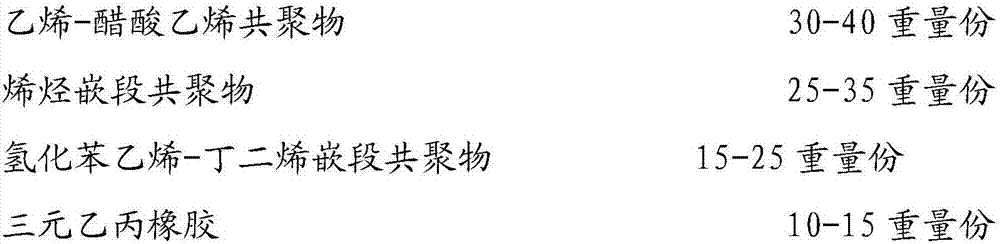

[0034] Wherein, 100 parts by weight of plastic granules consist of the following raw materials by weight:

[0035]

[0036] Wherein, the magnesium carbonate is in powder form with a particle size of 40-80 mesh.

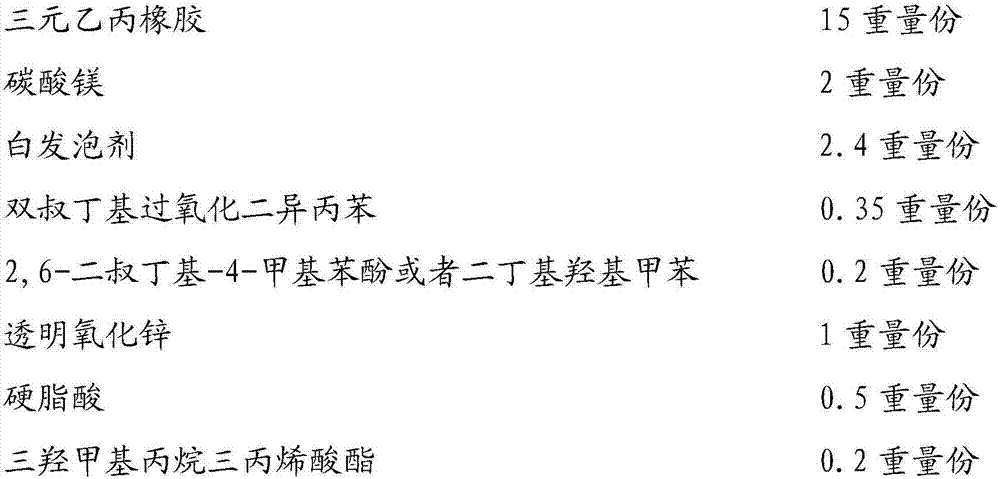

[0037] Through production practice, based on 100 parts by weight of plastic pellets, as a preferred embodiment, the ingredients are composed of the following raw materials by weight:

[0038]

[0039] As a preferred mode of the present invention, the ethylene-vinyl acetate copolymer model is EVA-265, purchased from DuPont Chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com