Optical diffusion barrier

An optical diffusion and diffusion film technology, applied in the field of optical diffusion film, can solve the problems of reduced light transmittance, long production cycle, adhesion, etc., and achieve the effects of sufficient diffusion performance, good antistatic properties, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

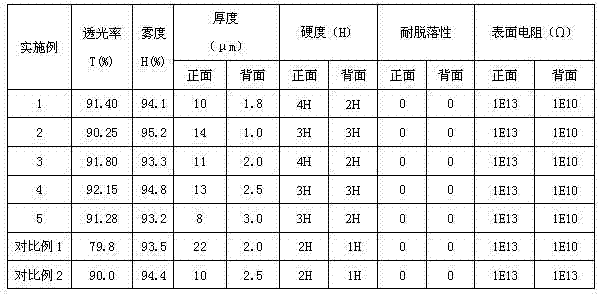

Examples

Embodiment 1

[0025] Preparation of diffusion layer coating solution:

[0026] EA 5 copies

[0027] 45 parts of 8-functionality PUA

[0028] 184 1.2 copies

[0029] 850 1.2 parts

[0030] BYK307 0.25 parts

[0031] Butanone 100 parts

[0032] 200 parts of toluene

[0033] PMMA microbeads (14μm) 161.5 parts

[0034] Silica (A-380) (2μm) 13.5 parts

[0035] Preparation of back coating solution:

[0036] PETA 5 copies

[0037] Caprolactone modified DPHA 45 parts

[0038] 184 1.2 copies

[0039] 850 1.2 parts

[0040] BYK307 0.20 parts

[0041] Butanone 250 parts

[0042] 100 parts of isopropyl alcohol

[0043] Silica (A-380, Degussa) (3μm) 9 parts

[0044] Antistatic agent (Adnano ITO, Degussa) 0.2 parts

[0045] Stir the above materials evenly, and apply the prepared diffusion layer coating material to one of the polyethylene terephthalate films (manufactured by China Lucky Film Group Corporation, trade name: FG22-188) as the substrate. On the surface, after drying th...

Embodiment 2

[0047] Preparation of diffusion layer coating solution:

[0048] EA 45 copies

[0049] 5 parts of 8-functionality PUA

[0050] 184 1.2 copies

[0051] 850 1.2 parts

[0052] BYK307 0.25 parts

[0053] Butanone 150 parts

[0054] 150 parts of toluene

[0055] Polystyrene microbeads (25μm) 150 parts

[0056] Titanium dioxide (4μm) 25 parts

[0057] Preparation of back coating solution:

[0058] PETA 45 copies

[0059] Caprolactone modified DPHA 5 parts

[0060] 184 1.2 copies

[0061] 850 1.2 parts

[0062] BYK307 0.20 parts

[0063] Butanone 200 parts

[0064] 150 parts of toluene

[0065] Titanium dioxide (2μm) 9 parts

[0066] Antistatic agent (Adnano ITO, Degussa) 0.2 parts

[0067] Stir the above materials evenly, and apply the prepared diffusion layer coating material to one of the polyethylene terephthalate films (manufactured by China Lucky Film Group Corporation, trade name: FG22-188) as the substrate. On the surface, after drying the formed coating at ...

Embodiment 3

[0069] Preparation of diffusion layer coating solution:

[0070] EA 15 copies

[0071] 35 parts of 8-functionality PUA

[0072] 184 1.0 copies

[0073] 850 1.4 parts

[0074] BYK307 0.25 parts

[0075] Butanone 100 parts

[0076] 50 parts of isopropyl alcohol

[0077] 150 parts of toluene

[0078] PMMA microbeads (16μm) 150 parts

[0079] Silica (A-380, Degussa) (2μm) 25 parts

[0080] Preparation of back coating solution:

[0081] PETA 15 copies

[0082] Caprolactone modified DPHA 35 parts

[0083] 184 1.2 copies

[0084] 850 1.2 parts

[0085] BYK307 0.20 parts

[0086] Butanone 175 parts

[0087] 175 parts of toluene

[0088] Calcium carbonate (3μm) 9 parts

[0089] Antistatic agent (Adnano ITO, Degussa) 0.2 parts

[0090] Stir the above materials evenly, and apply the prepared diffusion layer coating material to one of the polyethylene terephthalate films (manufactured by China Lucky Film Group Corporation, trade name: FG22-188) as the substrate. On the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com