Nano zinc oxide grafted aqueous UV light-cured polyurethane resin and preparation method thereof

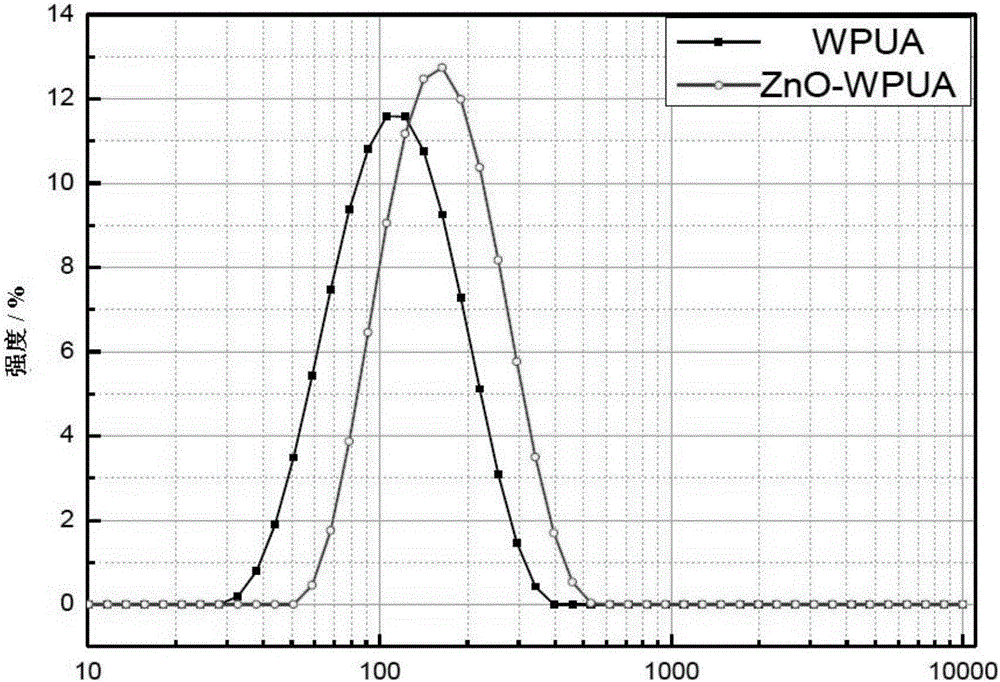

A technology of nano-zinc oxide and polyurethane resin, which is applied in the field of coatings, can solve the problems of complex modification process and high cost of modifiers, and achieve the effects of environmental friendliness, moderate particle size and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment of nano-zinc oxide: dry nano-zinc oxide in a vacuum drying oven at 60°C for about 3 hours at a relative vacuum pressure of -0.095MPa;

[0035] (2) Synthesis of polyurethane prepolymer I: Add 26.65g of toluene-2,4-diisocyanate (TDI-80) and 25.51g of polyether diol (M w =1000), drop 0.052g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 80°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0036] (3) Synthesis of polyurethane prepolymer II: cool down to 65°C, weigh 8.654g of dimethylolpropionic acid (DMPA), dissolve it with 18g of acetone, place it in a dropping funnel, drop it into a four-neck flask, drop The acceleration is 3-4s / drop, keep this temperature for 3 hours, add a proper amount of acetone to adjust the viscosity during the period, when the NC...

Embodiment 2

[0044] (1) Pretreatment of nano-zinc oxide: dry nano-zinc oxide in a vacuum drying oven at 60°C for about 3 hours at a relative vacuum pressure of -0.095MPa;

[0045] (2) Synthesis of polyurethane prepolymer I: Add 26.65g of toluene-2,4-diisocyanate (TDI-80) and 25.51g of polyether diol (M w =1000), add dropwise 0.052g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 85°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0046] (3) Synthesis of polyurethane prepolymer II: cool down to 65°C, weigh 8.654g of dimethylolpropionic acid (DMPA), dissolve it with 18g of acetone, place it in a dropping funnel, drop it into a four-neck flask, drop The acceleration is 3-4s / drop, keep this temperature for 3 hours, add a proper amount of acetone to adjust the viscosity during the period, whe...

Embodiment 3

[0056] (1) Pretreatment of nano-zinc oxide: dry nano-zinc oxide in a vacuum drying oven at 60°C for about 3 hours at a relative vacuum pressure of -0.095MPa;

[0057] (2) Synthesis of polyurethane prepolymer I: Add 26.65g of toluene-2,4-diisocyanate (TDI-80) and 25.51g of polyether diol (Mw =1000), drop 0.052g catalyst dibutyltin dilaurate, react in a constant temperature water bath, heat up to 80°C, keep this temperature for about 1.5h, and the NCO value of di-n-butylamine titration reaches or is slightly lower than the theoretical When the value is , the semi-blocked polyurethane prepolymer I is obtained;

[0058] (3) Synthesis of polyurethane prepolymer II: cool down to 65°C, weigh 8.654g of dimethylolpropionic acid (DMPA), dissolve it with 18g of acetone, place it in a dropping funnel, drop it into a four-neck flask, drop The acceleration is 3-4s / drop, keep this temperature for 3 hours, add a proper amount of acetone to adjust the viscosity during the period, when the NCO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com