Organic/inorganic compound flame-retardant rigid polyurethane foam and preparation method thereof

A rigid polyurethane and inorganic technology, applied in the field of thermal insulation materials, can solve the problems of limited large-scale application, low flame retardant efficiency of phosphorus-containing polyols, and high production costs, achieve good industrial production prospects, reduce construction difficulties, and improve resistance. flammable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

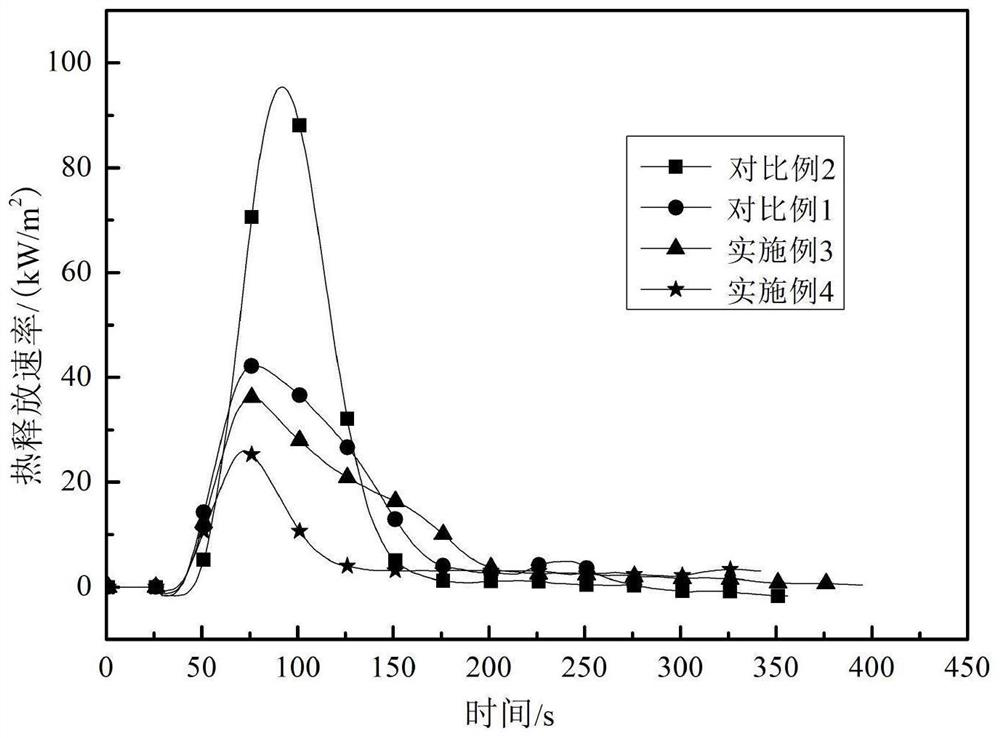

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the organic / inorganic composite flame-retardant rigid polyurethane foam, comprising the following steps:

[0033] 1) In a three-necked flask equipped with stirring, vacuum system, and thermometer, add DEEP, glycol, and catalyst;

[0034] 2) Slowly raise the temperature of the reaction system to 140-160° C. for transesterification for 3-3.5 hours;

[0035] 3) Ethanol is fractionally distilled off the product in step 2) under normal pressure, then decompressed and gradually heated to 165-180° C., and further esterified and condensed to obtain a phosphorus-containing polyol;

[0036] 4) Mix the prepared component A and component C, put it in the white material tank of the polyurethane foaming machine, and keep it warm at 35-45°C;

[0037] 5) Put component B in the black material tank of the polyurethane foaming machine, inject it into the interlayer of the high-density polyethylene outer protective tube at a pres...

Embodiment 1

[0043] In component A, the phosphorus-containing polyol is a phosphonate-type phosphorus-containing polyol, and its preparation method is as follows:

[0044] 1) Add 166g of DEEP, 70g of ethylene glycol, and 0.25g of dibutyltin oxide into a three-necked flask equipped with stirring, vacuum system, and thermometer;

[0045] 2) slowly raising the temperature of the reaction system to 150° C. for transesterification for 3 hours;

[0046] 3) Distill the ethanol from the product in step 2) under normal pressure, then depressurize and gradually heat up to 165°C for further esterification and condensation to obtain a hydroxyl value of 58mgKOH / g and an acid value of 0.7mgKOH / g at 25°C A phosphorus-containing polyol with a viscosity of 760mPa·S.

Embodiment 2

[0048] An organic / inorganic composite flame-retardant rigid polyurethane foam is composed of the following raw materials in parts by weight:

[0049]

[0050] Mix the prepared component A and MIL-53(Fe), put it in the white material tank of the polyurethane foaming machine, keep it warm at 45°C; then put component B in the black material tank of the polyurethane foaming machine, It is injected into the interlayer of the high-density polyethylene outer protective pipe at a pressure of 0.3Mpa, and foamed to obtain a finished organic / inorganic composite flame-retardant rigid polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com