Inhibitor with sustained release property and preparation method thereof

A chemical inhibitor and slow-release technology, which is applied in the field of slow-release inhibitors and their preparation, can solve the problems of increasing construction strength, increasing costs, and inconvenience in the spontaneous combustion process, so as to reduce construction strength, prolong flame retardant time, The effect of reducing the number of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The specific preparation process of the slow-release inhibitor in this embodiment is:

[0013] Put 2g of acrylonitrile-butadiene-styrene copolymer, 17.8g of acetone and 0.2g of alkylphenol polyoxyethylene ether in a three-necked flask, and stir mechanically at room temperature until the emulsion is transparent; weigh 18g of calcium chloride Add it to the above emulsion, reflux at 40°C, condense and mechanically stir for 2 to 3 hours, then place the resultant in an oven, bake at 60 to 80°C for 6 to 8 hours, and grind to obtain the slow-release product of the present invention. inhibitors.

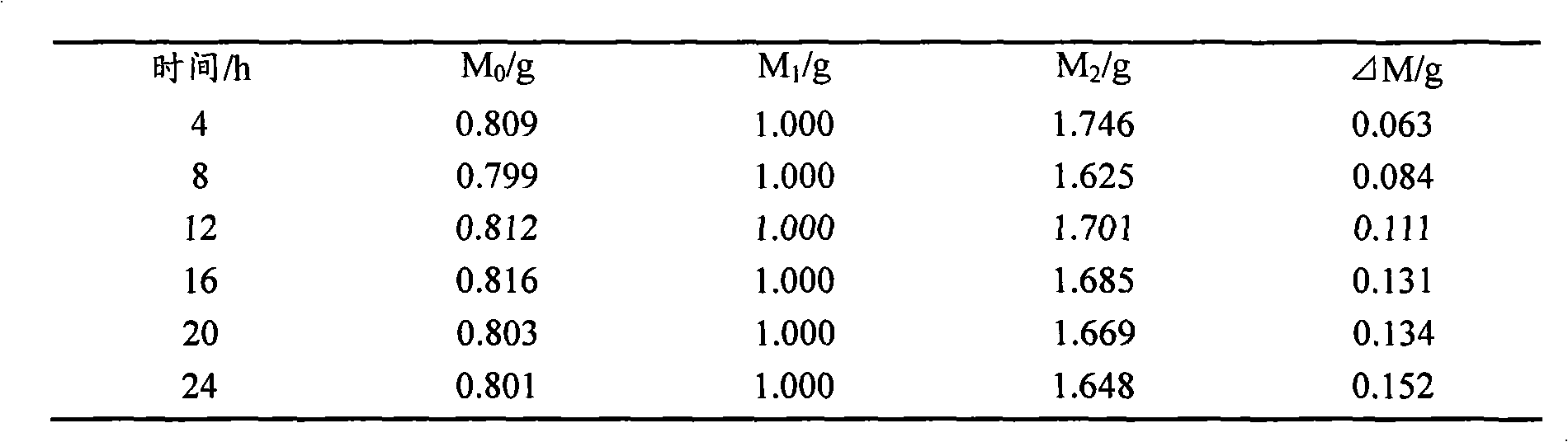

[0014] The slow-release inhibitor prepared in this example, its slow-release detection method is:

[0015] The first step, first weigh 1g of the inhibitor product prepared in this embodiment, and the quality is recorded as M 1 , then weigh the mass of a piece of filter paper, denoted as M 0 , and then wrap the product with filter paper;

[0016] In the second step, weigh five grou...

Embodiment 2

[0023] Put 3g of acrylonitrile-butadiene-styrene copolymer, 16.8g of acetone and 0.2g of alkylphenol polyoxyethylene ether in a three-necked flask, and mechanically stir at room temperature until the emulsion is transparent; then add 18g of magnesium chloride at 40°C Reflux and condense and mechanically stir for 2-3 hours, then place the resultant in an oven, bake at 60-80°C for 6-8 hours, and pulverize to obtain the slow-release inhibitor of the present invention.

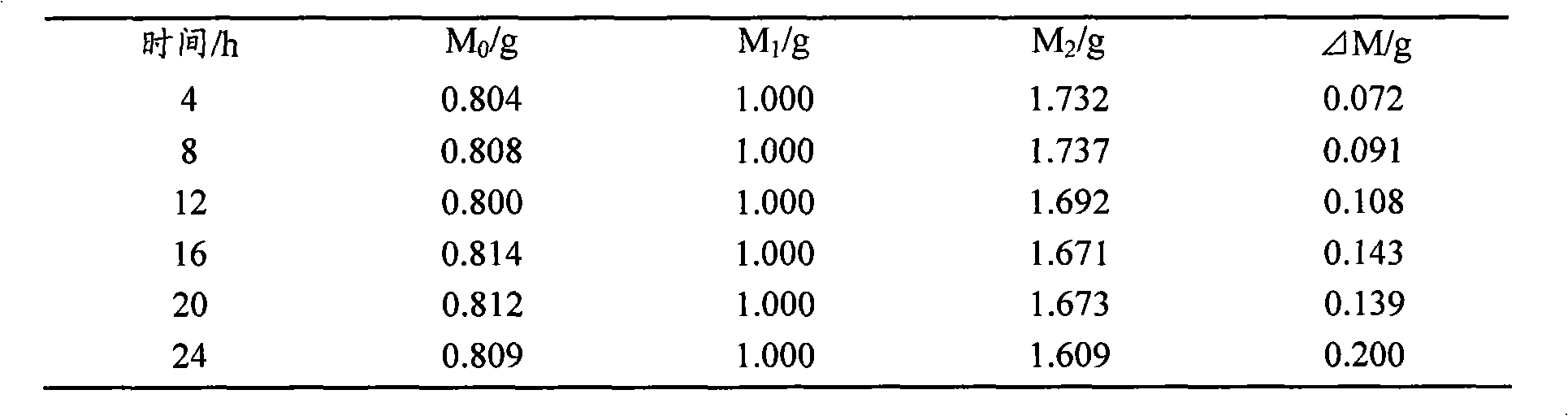

[0024] Detect the sustained release of the inhibitor prepared in this embodiment:

[0025] The first step, first weigh 1g of the product inhibitor of this embodiment, and the quality is recorded as M 1 , then weigh the mass of a piece of filter paper, denoted as M 0 , and then wrap the product with filter paper;

[0026] In the second step, weigh five groups of samples in the same way and wrap them with filter paper; stack these six groups of samples in turn in a beaker with a capacity of 500ml, and place a piec...

Embodiment 3

[0033] Put 4g of polymethyl methacrylate, 15.8g of acetone and 0.2g of alkylphenol polyoxyethylene ether in a three-necked flask, and mechanically stir at room temperature until the emulsion becomes transparent; then add 17g of potassium chlorate and reflux at 50°C to condense and mechanically stir After 2-3 hours, put the resultant in an oven, bake it at 60-80°C for 6-8 hours, and pulverize it to obtain the slow-release inhibitor of the present invention.

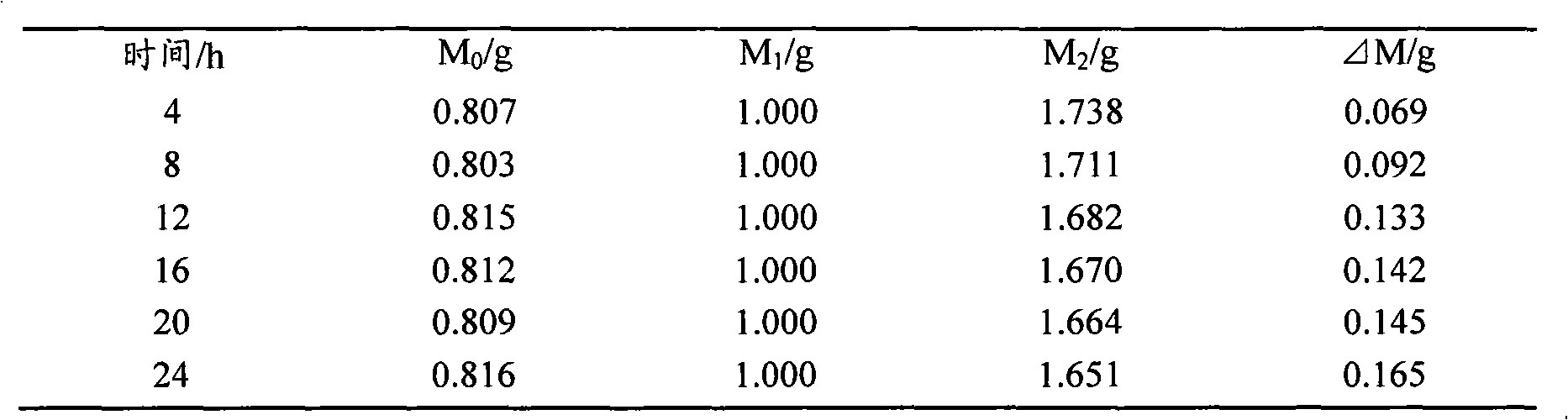

[0034] The sustained-release detection of the inhibitor prepared in this embodiment:

[0035] The first step is to weigh 1g of the inhibitor product first, and record the mass as M 1 , then weigh the mass of a piece of filter paper, denoted as M 0 , and then wrap the product with filter paper;

[0036] The second step is to weigh five groups of samples in the same way, stack these six groups of samples in turn in a beaker with a capacity of 500ml, and place a piece of filter paper between each two groups of samples and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com