Preparation method of magnesium-based desulfurizing agent

A magnesium-based desulfurizer and desulfurizer technology, which is applied in the field of metallurgical molten iron desulfurization, can solve the problems of low automation, easy pollution, and short flame retardant time, and achieve high automation, low environmental pollution, and long flame retardant time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

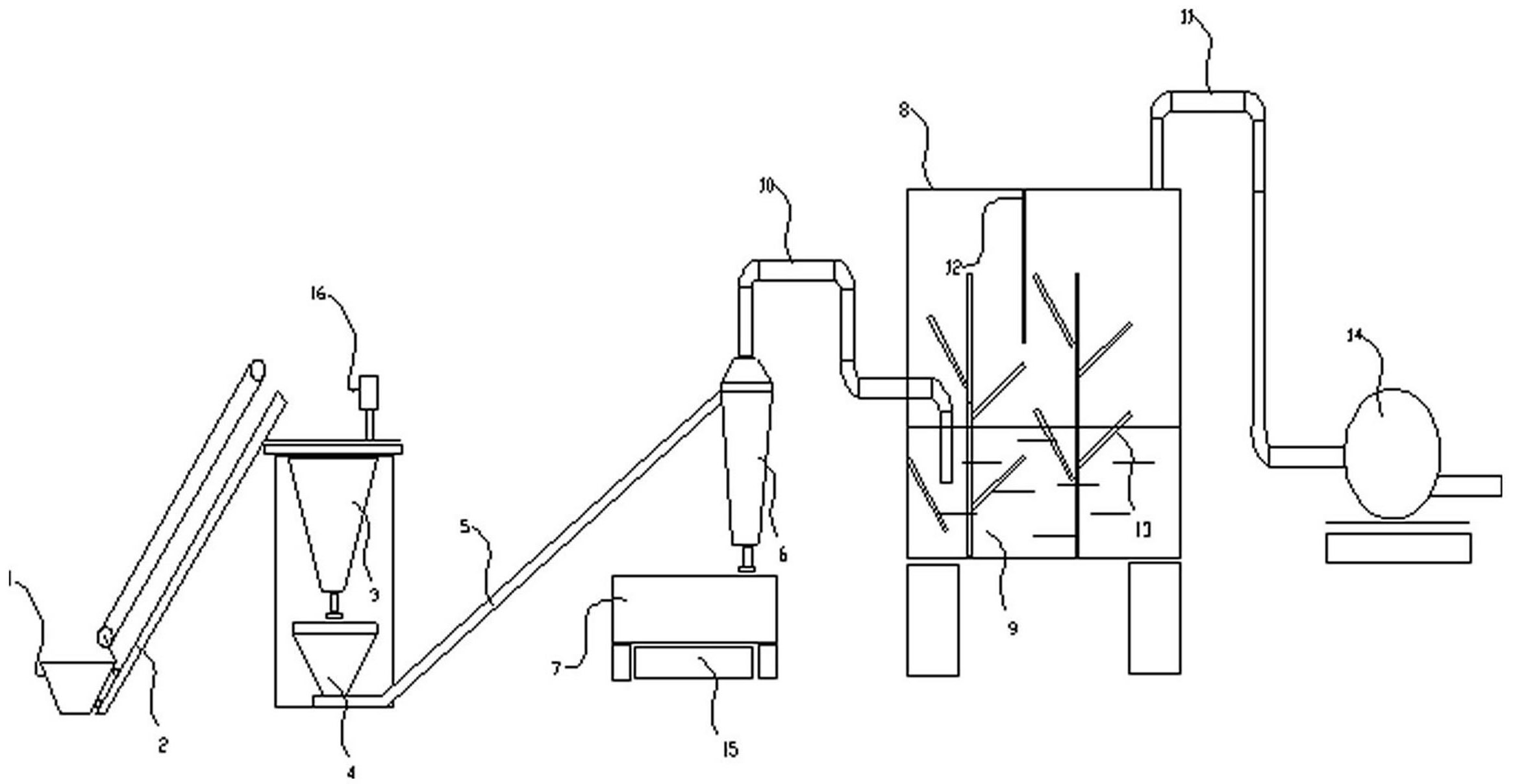

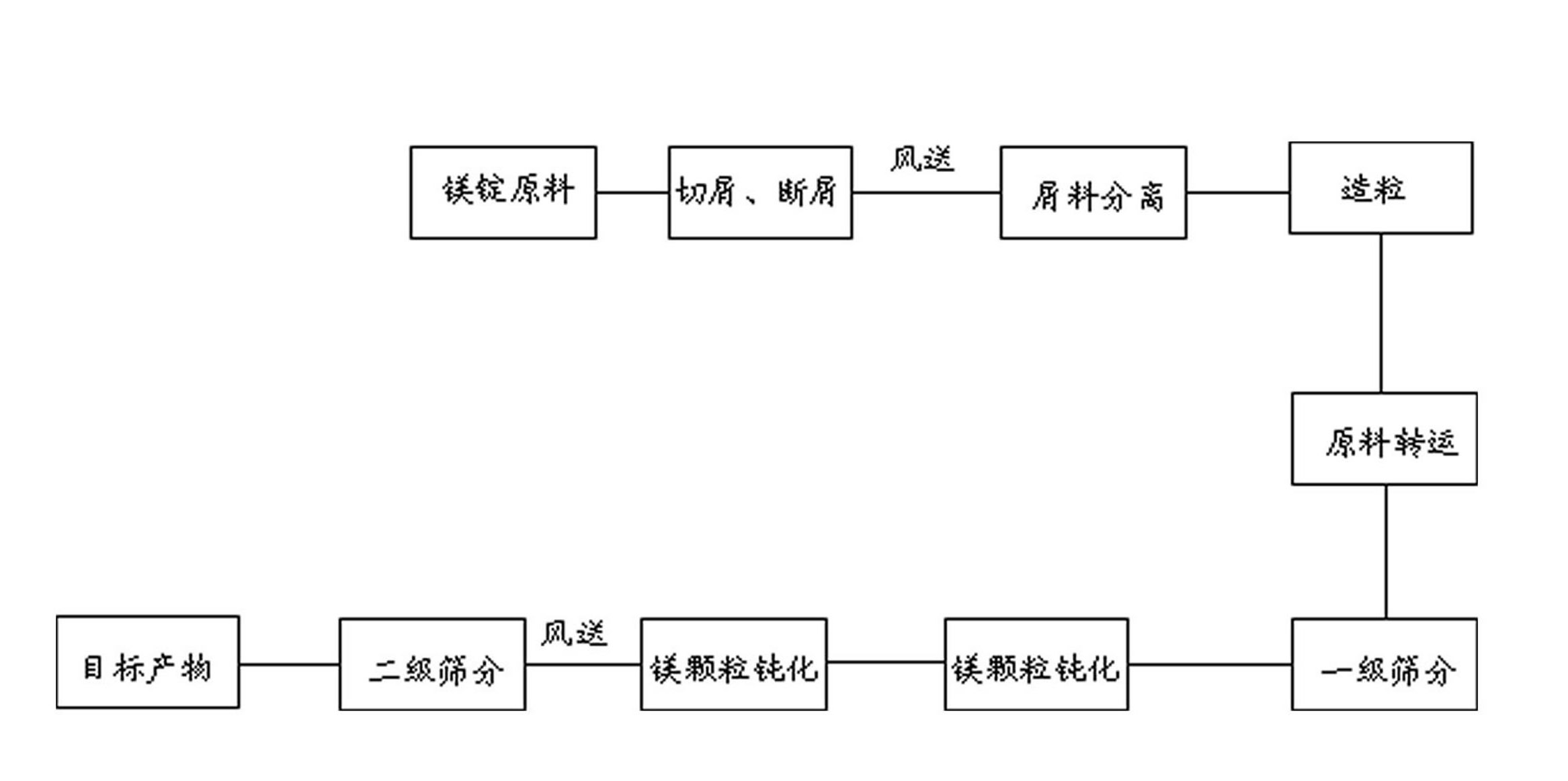

[0020] As shown in the figure, the preparation method of the magnesium-based desulfurizer can be implemented sequentially according to the following steps.

[0021] (1) Preparation of raw materials: firstly, the raw materials of magnesium ingots are chipped and broken, and sent to the chip separator for material separation; secondly, the separated magnesium materials are sent to the granulator for granulation grain.

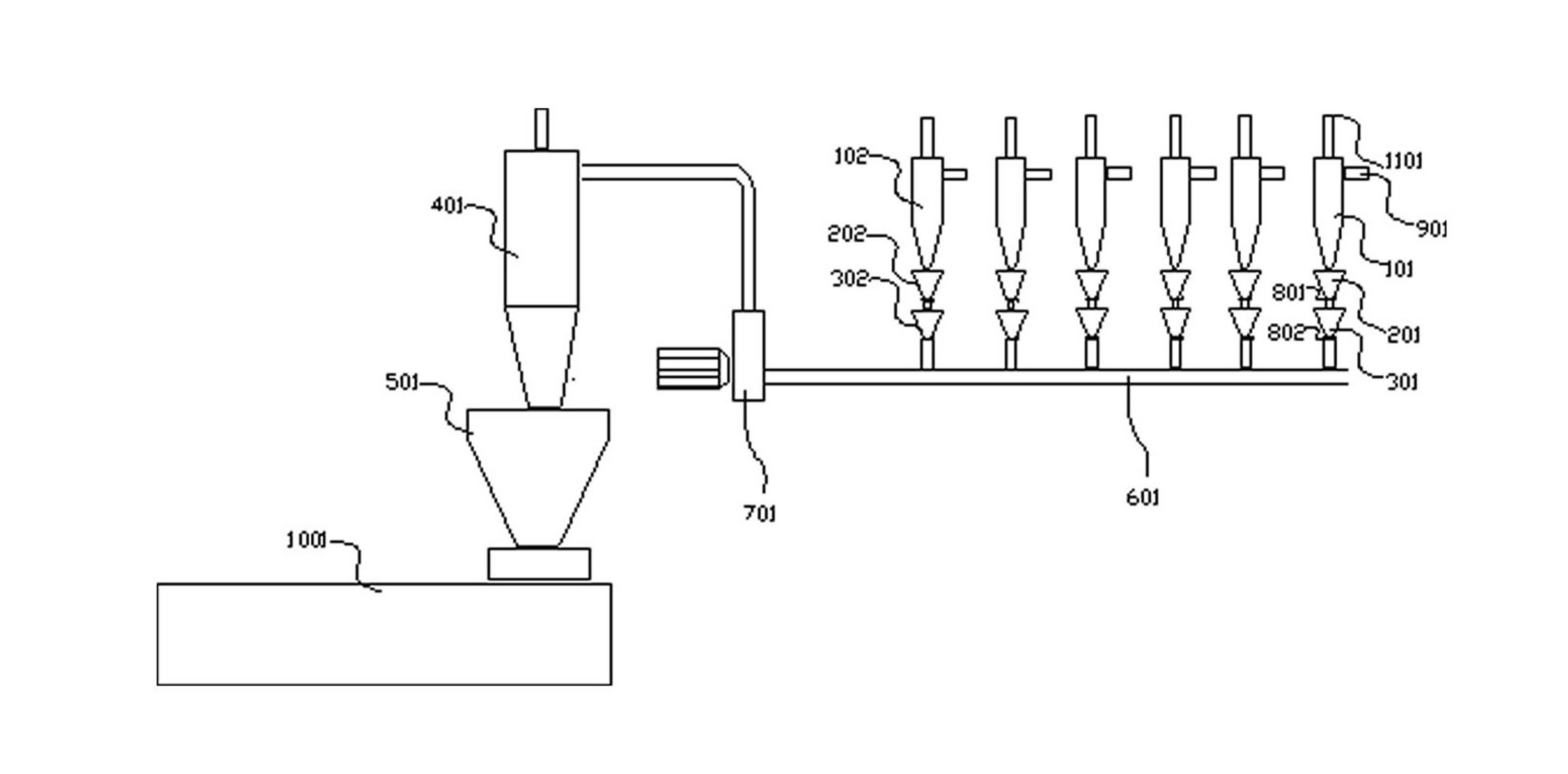

[0022] (2) Transport and screening of magnesium particles: see figure 2 , the product described in step (1) is sent to the inlet of the first group of cyclone tanks 101, and then enters the first group of primary blanking bins 201 from the outlet of the first group of cyclone tanks 101, and then the first group of one The discharge port of the first-stage blanking bin 201 enters the first group of secondary blanking bins 301, and then is sent to the last-stage cyclone tank 401 by the air duct 601 and the fan 701, and finally enters the final-stage storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com