Si-N flame retardance high wet modulus viscose fiber and preparation method thereof

A technology of high wet modulus viscose and fiber, which is applied in the field of high wet modulus viscose fiber and its preparation, silicon nitrogen flame retardant high wet modulus viscose fiber and its preparation, and can solve the problems of dry and wet state strength and Low wet modulus, poor stability, slow combination of flame retardant and fiber, etc., achieve high dry and wet strength, improve bonding strength, and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

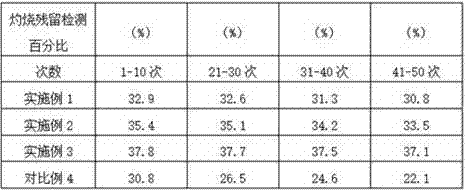

Examples

Embodiment 1

[0034] 1. Preparation of spinning dope:

[0035] Mix five batches of cotton and wood pulp with a degree of polymerization of about 830 and a cellulose content ≥ 95% in any proportion, then fully mix with the impregnating lye, and pass through 238±1g / L, 50℃ sodium hydroxide alkali solution After soaking for 60 minutes, press to make alkali cellulose; the alkali cellulose is crushed and aged, the aging temperature is 22°C, and the aging time is 1 hour; then it is mixed with CS 2 Mix and carry out yellowing reaction, yellowing temperature is 18°C, yellowing time is 60 minutes, and the amount of carbon disulfide added to methyl cellulose is 34% during yellowing to generate cellulose xanthate; after initial dissolution of cellulose xanthate in dilute alkali solution To obtain the spinning stock solution, add 4.5% denaturant of p-methylcellulose in the later stage of dissolution, which is composed of 3% PEG and 1.5% hydroxyethylamine; the spinning stock solution is followed by post-...

Embodiment 2

[0047] 1. Preparation of spinning dope:

[0048] Five batches of cotton and wood pulp with a degree of polymerization of about 1000 and a cellulose content ≥ 95% are mixed in any proportion and fully mixed with the impregnating lye, and then pressed to make alkali cellulose after impregnation; Crushing, aging treatment, aging temperature 26 ℃, aging time 120min; then with CS 2 Mix for yellowing reaction, yellowing temperature is 19°C, yellowing time is 65min, and the amount of carbon disulfide added to methyl cellulose is 36% during yellowing to generate cellulose xanthate; after initial dissolution of cellulose xanthate in dilute alkali solution To obtain the spinning stock solution, add 3% denaturant of p-methylcellulose in the later stage of dissolution, and its composition is 2% polyoxyethylene alkylphenol ether and 1% cyclohexylamine; the spinning stock solution is successively dissolved and filtered three times , defoaming, and aging to obtain spinning stock solution. ...

Embodiment 3

[0058] 1. Preparation of spinning dope:

[0059] Five batches of cotton and wood pulp with a degree of polymerization of about 1380 and a cellulose content ≥ 95% are mixed in any proportion and fully mixed with the soaking lye. After pulverization, aging treatment, aging temperature: 29 ℃, aging time 210min; and then with CS 2 Mix and carry out yellowing reaction, add 40% of carbon disulfide to methyl fiber during yellowing to generate cellulose xanthate; cellulose xanthate is initially dissolved in dilute alkali solution to obtain spinning stock solution, and add methyl fiber in the later stage of dissolution Fiber 2.5% denaturant, which is composed of 1.5% polyoxyalkylene glycol and 1.0% diethylamine; the spinning stock solution is followed by post-dissolution, three-way filtration, defoaming, and aging to obtain the spinning stock solution. Spinning dope index: methyl fiber: 9.8wt%, containing 8.9% alkali, esterification degree 68, viscosity 85S.

[0060] 2. Two pre-spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com