Aqueous thin coating type aluminum alloy fireproof coating material and preparation method thereof

A technology of fire retardant coatings and aluminum alloys, applied in fire retardant coatings, antifouling/underwater coatings, polyester coatings, etc., can solve problems such as weak adhesion, thick coating thickness, property loss, etc. The effect of transparent film and strong aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

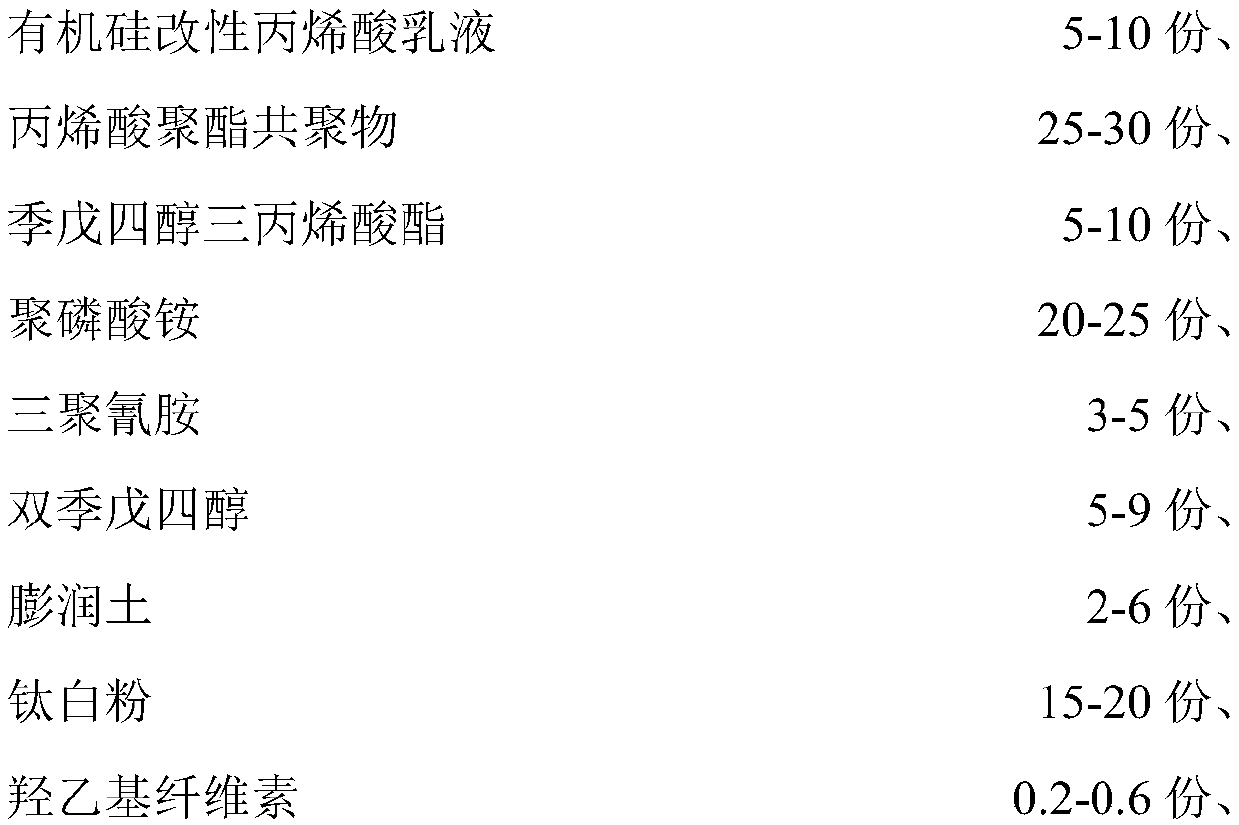

[0038] A kind of water-based thin coating type aluminum alloy fireproof coating of the present invention, this water-based thin coating type aluminum alloy fireproof coating is formed by mixing the raw materials of following parts by weight:

[0039]

[0040] The preparation method of the water-based thin coating type aluminum alloy fireproof coating of the present embodiment may further comprise the steps:

[0041] (1) Mix and disperse 90% water, 80% silicone-modified acrylic emulsion, 80% acrylic polyester copolymer, defoamer, all hydroxyethyl cellulose and dispersant at 1000r / min 5-15 minutes, after dispersing evenly, add titanium dioxide, melamine, dipentaerythritol, pentaerythritol triacrylate, bentonite, increase the speed to 1500r / min, continue stirring and dispersing for 15-25 minutes, and obtain a mixed slurry after dispersing evenly;

[0042] (2) Add remaining 20% silicone modified acrylic emulsion, acrylic polyester copolymer and defoamer while stirring in the ...

Embodiment 2

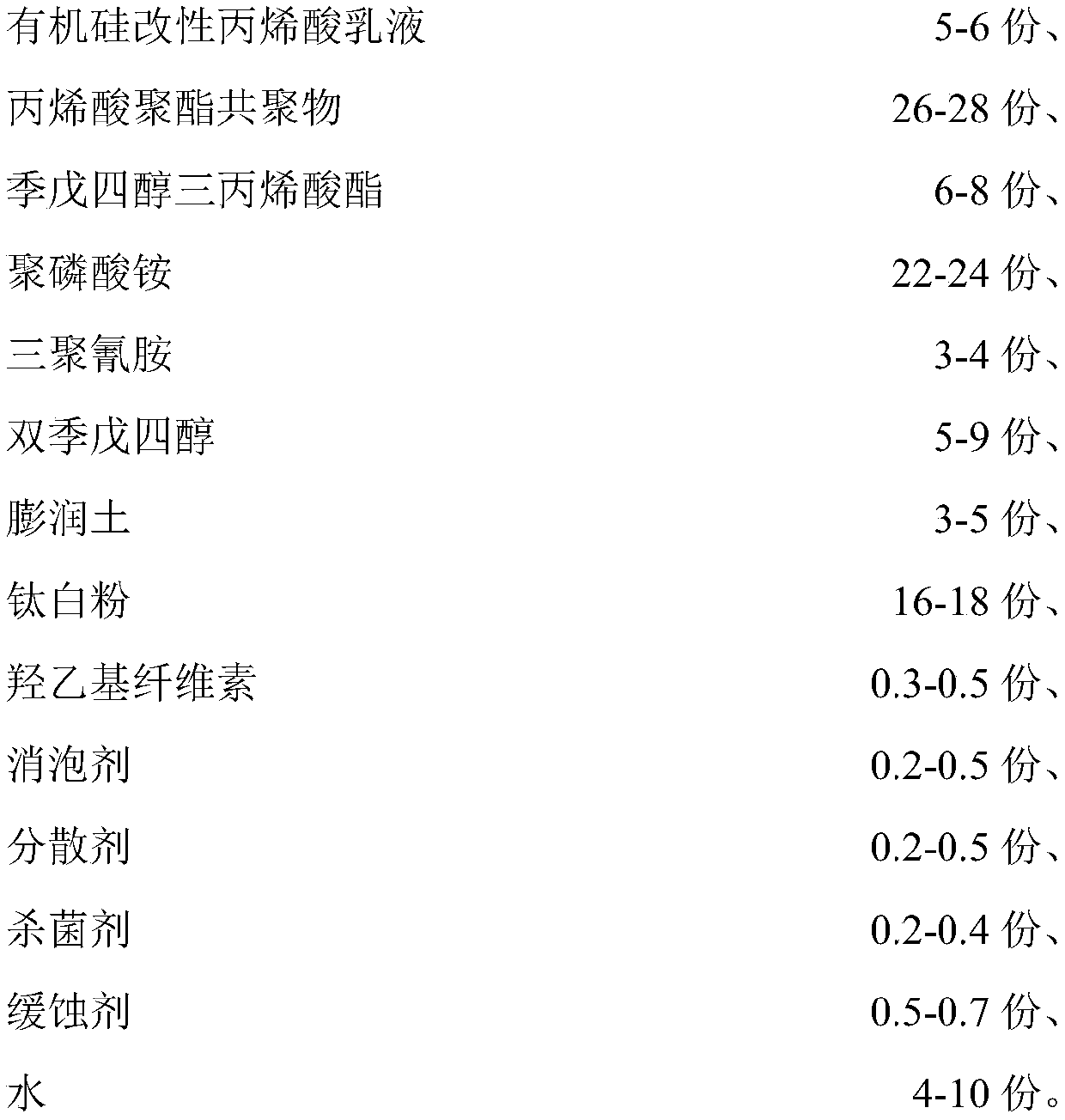

[0045] A kind of water-based thin coating type aluminum alloy fireproof coating of the present invention, this water-based thin coating type aluminum alloy fireproof coating is formed by mixing the raw materials of following parts by weight:

[0046]

[0047] The preparation method of the water-based thin coating type aluminum alloy fireproof coating of the present embodiment may further comprise the steps:

[0048] (1) Mix and disperse 90% water, 80% silicone-modified acrylic emulsion, 80% acrylic polyester copolymer, defoamer, all hydroxyethyl cellulose and dispersant at 1000r / min 5-15 minutes, after dispersing evenly, add titanium dioxide, melamine, dipentaerythritol, pentaerythritol triacrylate, bentonite, increase the speed to 1500r / min, continue stirring and dispersing for 15-25 minutes, and obtain a mixed slurry after dispersing evenly;

[0049] (2) Add remaining 20% silicone modified acrylic emulsion, acrylic polyester copolymer and defoamer while stirring in the ...

Embodiment 3

[0052] A kind of water-based thin coating type aluminum alloy fireproof coating of the present invention, this water-based thin coating type aluminum alloy fireproof coating is formed by mixing the raw materials of following parts by weight:

[0053]

[0054] The preparation method of the water-based thin coating type aluminum alloy fireproof coating of the present embodiment may further comprise the steps:

[0055] (1) Mix and disperse 90% water, 80% silicone-modified acrylic emulsion, 80% acrylic polyester copolymer, defoamer, all hydroxyethyl cellulose and dispersant at 1000r / min 5-15 minutes, after dispersing evenly, add titanium dioxide, melamine, dipentaerythritol, pentaerythritol triacrylate, bentonite, increase the speed to 1500r / min, continue stirring and dispersing for 15-25 minutes, and obtain a mixed slurry after dispersing evenly;

[0056] (2) Add remaining 20% silicone modified acrylic emulsion, acrylic polyester copolymer and defoamer while stirring in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com